Site pages

Current course

Participants

General

20 February - 26 February

27 February - 5 March

6 March - 12 March

13 March - 19 March

20 March - 26 March

27 March - 2 April

3 April - 9 April

10 April - 16 April

17 April - 23 April

24 April - 30 April

Lesson 7. METAL CUTTING

Module 4. Heat treatment process

MEATL CUTTING

All metal cutting operations basically involve forcing a cutting tool with one or more cutting edges progressively through the excess material on the work piece. The work piece and the tool are securely held in a machine tool and its accessories while power is supplied to provide relative motion between the tool and the work piece. This results in removal of any excess material interfering with the relative motion in the form of chips. Metals are cut primarily to produce surfaces of desired shape, accuracy or surface finish depending upon their use. Since all machining involves considerable amount of labour, cost and loss of material as chips, machining should never be overdone to the extent of producing surfaces which are more accurate or better finished than those required for proper functioning of the product.

7.2 The Machine Tool

Machining is done with the help of power driven non-portable machines known as machine tools in order to perform its function. The machine tool must incorporate means for holding the workpiece and the tools and for providing relative motion between the tool and the workpiece. The form of surface produced in a particular machine tool depends upon the shape of the cutting tool, the path of the tool as it traverses through the material or both. If the tool moves past the workpiece in a linear path as in shaping or vice versa as in planning a straight cut plane surface is produced. On the other hand, if either the tool (boring) or workpiece (turning) is rotating and the other unit is travelling in a definite path relative to the axis, a surface of revolution is generated. Machining operations are named and classified according to the shape of the cutter, nature of relative movement, shape of the generated surface and the type of finish.

Performance wise a machine tool is expected to satisfy the following requirements:

1. It must have a high efficiency.

2. It must be possible to produce the specified dimensional accuracy, surface finish and form consistently and preferable independent of operator’s skill.

3. It should have a high enough production rate corresponding to latest development in technology.

7.2.1 Types of machine tools

Machine tools of different types and sizes have been developed because of variation in shape of the surface to be machined, size of the workpiece, surface accuracy desired and quantity required to be produced.

Broadly speaking machine tools may be classified into three major categories:

1. General purpose machine tools.

2. Production machine tools.

3. Special purpose machine tools.

1. General purpose machine tools

General purpose machine tools are machine tools like lathe, drilling machine and milling machine that are designed to deal with a variety of work and can perform a reasonably large number of operations within their range. A lathe, for example, can be used to do turning, knurling, threading or tapering on a job held between centres, turning, drilling, boring or facing on a job held in a chuck, turning, boring or facing on a job held on the face plate or boring in work held on the carriage using a boring bar held in the spindle. It can also be used for milling, grinding ore relieving with suitable attachments. Similarly a milling machine can be used for plain milling, slotting, angular cutting, indexing or helical milling operations. General purpose machine tools are useful in smaller machine shops and repair shops or for small quantity production.

2. Production Machine Tools

Production machine tools are designed to increase the rate of production and to reduce the manufacturing costs. Features like multiple spindle heads, multi-tool turrets and specially designed fixtures are incorporated in these machine tools to reduce the non-productive time or to combine more than one operation. Typical examples of this category are capstan and turret lathes, automatic screw machines, multi-spindle drilling machines and production milling machines. They are used for medium size production and batch work.

3. Special Purpose Machine Tools

Special purpose machine tools are machines which have been designed for some specific purpose and perform only one or a limited number of operations. Machines of this category include cam shaft grinders, gear generators and piston turning lathes. Special purpose machines, in most cases, perform operations that may be done on basic machines but for larger quantities they are much more economical than standard machine tools.

7.3 Cutting Tools

Metal cutting tools may be classified as single-point, double-point or multi-point tools depending upon the number of active cutting edges on the tool. Tools used on lathe, shaper or planer have a single cutting edge and are called single-point tools. Drilling tools have two cutting edges while milling cutters, in general, have more than two cutting edges. Grinding is a more general form of multi-point cutting in that the abrasive grains taking part in cutting do not have any fixed geometry or orientation. As far as their metal cutting action is concerned a double or multi-point tool behaves just the same way as a combination of so many single-point tools. The properties of cutting tools are thus discussed with reference to single point tools of the type used on lathe for turning.

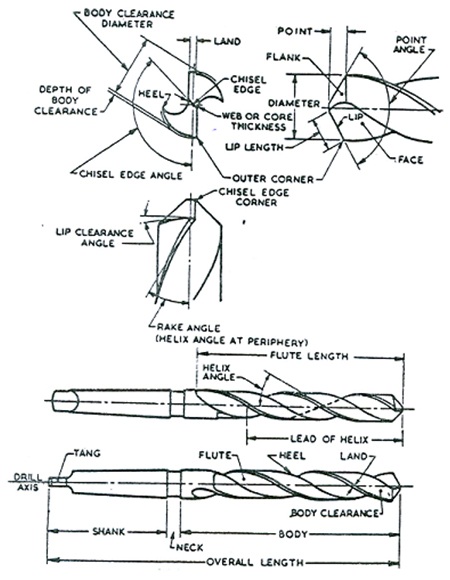

Fig. 7.1 Twist drill nomenclature

In order for a machining operation to proceed at a fast rate with minimum tool and machining cost the cutting tool material must satisfy certain basic requirements. The more important of these requirements are given below:

7.4.1 Hot hardness

This represents the capacity of the tool to retain its cutting ability and hardness at the high temperatures developed at the chip-tool interface. To be effective the tool material must remain harder than the work material at all temperatures. Hot hardness of the tool material becomes more significant as the cutting speed is increased or the hardness of the metal to be machined becomes higher.

7.4.2 Wear resistance

The life of a tool is determined by the wear developed on its cutting face due to motion of the chip and on its flanks due to contact with the machined surface. In order for the tool to continue to perform its duties satisfactorily it is important that the wear characteristics of its material relative to that of the work piece are such that excessive tool wear does not occur during the machining process.

7.4.3 Toughness

Toughness is necessary to enable the tool to withstand cutting forces, to absorb shock and to prevent the chipping of the cutting edge. The tool must not become so hard that it becomes brittle. Toughness is particularly important for tools like milling cutters which are subjected to impact loading due to interrupted cutting.

7.4.4 Low friction

The co-efficient of friction between the tool material and the chip should be low. This is important for reducing tool forces, keeping chip-tool interface temperature low, increasing tool life and improving surface finish.

7.4.5 Thermal conductivity

A material with a high thermal conductivity can conduct heat away from the chip tool interface faster. This results in a lower chip-tool interface temperatures, less interface welding and longer tool life.

7.4.6 Cost

This includes the cost of material, cost of grinding and the cost of replacement when the tool is worn out. A cheap material that requires frequent stopping of the machine for tool changing may prove much costlier in the long run compared to the one which has a higher initial cost but can be operated for a longer time at a higher speed.

The properties of the tool material as outlines above are often contradictory and inter-dependent. For example, a material that has a good wear resistance will not generally have high toughness. There is no single tool material that satisfies all the requirements specified above.

7.5 Commonly Available Tool Materials and Their Characteristics are Discussed Below

Carbon tool steels contain carbon in amount ranging from 0.90 to 1.20 percent. These steels are relatively cheap and the tools are relatively easy to make and harden. With proper heat treatment these steels can attain hardness as much as any of the high speed alloys but they begin to lose their hardness at around 300oC. Cutting tools of carbon steels are limited to show speeds and light duty work. Carbon steels are used for machining soft materials like wood and for hand tools like files and chisels.

7.5.2 High speed steels

High speed steels were so named because they could cut at speeds higher than those of carbon steels. The name is misleading because the speeds at which these materials cut are actually much lower than those used for many other materials like carbides and stellites that are now available.

High speed steels have excellent hardenability and can retain their hardness up to 650oC. They are relatively tough and moderately priced. They can be shaped easily. As such high speed steels are commonly used for drills, reamers; counter bores, milling cutters and single point tools. One of the oldest and the most common variety of high speed steels is 18-4-1. It contains 18 percent tungsten, 4 percent chromium, 1 percent vanadium and about 0.5 to 0.75 percent carbon. It is considered to be one of the best all purpose tool steels. Many high speed steels use molybdenum to replace tungsten partially or completely because one part of molybdenum can replace two parts of tungsten. Molybdenum high speed steels such as 6-6-4-2 containing 6 percent tungsten, 6 percent molybdenum, 4 percent chromium and 2 percent vanadium with about 0.6 percent carbon have excellent toughness and cutting ability.

Cobalt is sometimes added to high speed steels to improve their red-hardness. These super high speed steels are used for heavy cutting operations involving higher cutting pressures and temperatures on the tool but are too costly for general purpose work. One composition of these super high speed steel alloys contains 20 percent tungsten, 4 percent chromium, 2 percent vanadium, and 12 percent cobalt.

High speed steels have one major disadvantage in that they require lot of care in heat treatment. Rather complex heat treatment cycles are used to develop the most favourable properties.

7.5.3 Cast non-ferrous alloys

These are alloys containing principally chromium cobalt and tungsten with smaller percentages of one or more carbide forming elements like tantalum, molybdenum and boron but no iron. They also contain 1 to 4 percent carbon. A typical alloy of this type known as stellite contains 30 to 35 percent chromium, 43 to 48 percent cobalt, 17 to 19 percent tungsten and about 2 percent carbon.

Cast non-ferrous alloys are able to maintain good cutting edges up to 900oC. Compared with high speed steels they can be used at twice the cutting speeds. They have a good resistance to cratering. They can take a good polish which helps metal from sticking on the tool face and forming the built-up-edge. They are also corrosion resistant. But they are brittle, can be machined only by grinding and do not respond to heat treatment. Intricate tools can only be made by casting and grinding.

7.5.4 Carbides

Carbide cutting tool inserts principally consist of tungsten carbide particles held together by cobalt or nickel as binder. Straight tungsten carbide tools containing about 94 percent tungsten carbide and 6 percent cobalt are used for machining cast iron and most other materials. They cannot be used for machining steel because the chips tend to stick to the tool. Tantalum, Titanium carbides are added in steel cutting tungsten carbide grades in addition to increasing their cobalt content to overcome this difficulty. A typical analysis of a steel cutting grade may contain 82 percent tungsten carbide, 10 percent titanium carbide and 8 percent cobalt. Such a carbide has very low coefficient of friction and thus has less tendency for sticking.

Carbide tools are made by powder metallurgy techniques. They have a high initial cost but can be used at speeds which are two-to-three times those for cast nonferrous alloys. They can retain their cutting edges up to 1200 oC. They are very hard and have a high compressive strength but they are brittle and cannot withstand impact loading. Grinding is difficult and can only be done with silicon carbide or diamond wheels. Because of these reasons carbide tools are generally used as brazed or throw-away inserts. Even they have to be rigidly clamped. The need to provide high rotational speeds and yet assure extreme rigidity has led to considerable improvement in the design of machine tools used with these inserts.

7.5.5 Ceramics

Ceramics, sintered oxides, or cemented oxides are essentially aluminum oxide powder along with additives of titanium, magnesium or chromium oxide with a binder processed by powder metallurgy in the form of tool inserts. These inserts are either clamped into a tool holder or bonded to it. Ceramics are harder than other materials discussed so far and retain their hardness up to 1100 o C. They have a low coefficient of friction and a good resistance to cratering. The surface finish produced by ceramics is comparable with that produced by carbides but ceramics consume about 20 percent lesser power. The use of ceramic tools is limited only by their brittleness and the lack of rigidity and speed range on the conventional machine tools.

7.5.6 Diamond

Diamond is the hardest known material and can be used for machining at very high cutting speeds up to 25 m/s. Because of its high cost diamond is justified only when machining hard materials which are difficult to cut with other tool materials or for applications where very high accuracy and surface finish are desired. Diamond is also brittle, does not conduct heat well and can take only light cuts. Typical applications are precision boring of holes and machining of highly abrasive materials like fiber glass. Diamonds are also used for dressing grinding wheels and in finishing operations like lapping, honing and super finishing. When uses as cutting tools diamonds must be held very rigidly to avoid shock loading.

7.6 Cutting Parameters

Cutting speed, Feed and depth of cut:

Cutting speed, feed and depth of cut are the parameters which determined the relative motion of the tool and work piece in a cutting operation and represent the rate at which excess material is removed per unit time. A proper selection of these parameters is essential for efficient machining.

7.6.1 Cutting speed

The cutting speed is defined as the surface rate of travel of the cutting edge relative to the work piece. It is expressed in meters per second. The amount of heat generated at the chip tool interface during a machining operation and the life of the tool are directly influenced by the cutting speed.

The speed selected for any operation depends on the work material, cutting tool material, cutting fluid used and the type of cut. Lower speeds are used for harder materials and for heavier roughing cuts while finishing cuts in softer materials can be taken at much higher speeds.

7.6.2 Feed

Feed is defined as the rate at which the cutting tool advances along or into the surface of the work piece. For machines in which either the job or the tool rotates, feed is expressed in millimeters per revolution of the rotating member. For machines in which the work piece or tool reciprocates feed is expressed as millimeters per stroke. Other methods of expressing feed include feed in millimeters per second or millimeters per tooth of the cutter.

Feed has an important influence on the tool forces and surface finish. Lower feed values have to be used when machining with higher speeds, harder work pieces, less rigid machine tools, lesser supply of cutting fluid or a blunt tool.

7.6.3 23xDepth of cut

Depth of cut is the normal distance from the original surface to the surface being exposed by the tool. It is measured in millimeters. Either tool or work piece may be moved to give depth of cut depending upon the machine.

It must be pointed out that the direction of feed and depth of cut must be established carefully with reference to the type of operation. On a lathe for example, the longitudinal movement of the tool along the length of the bed constitutes feed motion in plain turning but a depth motion in facing. Similarly the motion at right angles to the bed axis with the help of cross slide constitutes a depth motion for turning but a feed motion for facing.

7.7 Cutting Fluids

7.7.1 Functions of the cutting fluid

Cutting fluids are used in metal cutting primarily for two reasons:

1. To reduce friction at the tool work and tool chip contact zones lubricating action.

2. To dissipate the heat generated during the cutting process – cooling action.

In addition, cutting fluids also help in washing away the chips from the cutting zone and in lubricating some of the moving parts of the machine.

The lubricating action of the cutting fluids reduces forces, increase tool life, reduces the tendency to form built-up-edge and improves surface finish. Since in metal cutting the ratio of real area of contact to the apparent area of contact is very close to unity and contact pressures are very higher, there is no possibility of fluid film existing between the surfaces in contact. The lubricating action of the cutting fluid is primarily due to the formation of a low shear strength film in the metal surface which can be easily sheared. The formation of such films takes time. Therefore, lubricating action of cutting fluids is not very predominant for high speed machining operations such as grinding. Again, the chemical properties of the cutting fluid are more important than its physical properties. Additives are often added to the fluids to improve their lubricating properties.

The cooling action of the cutting fluid helps carry away the heat generated during cutting and hence helps in retaining the strength of the tool. Cooling the work piece also helps in maintaining the dimensional accuracy by reducing the distortion caused due to heat. It also makes work handling easier. Amongst all the fluids, water based fluids are the most efficient for cooling because of their high specific heat and thermal conductivity. Compared to oils, water based fluids are two to three times faster. But water is likely to cause corrosion of machine parts. Anti-corrosive additives are mixed with water based coolants to control this corrosive action.

7.7.2 Types of cutting fluids

The cutting fluids commonly used may be divided into : (i) neat oils (ii) water soluble oils (iii) synthetic coolants and (iv) gaseous fluids.

(i) Neat oils: Neat oils or straight cutting oils are mineral oils, vegetable oils or combination of these two. Neat oils can be further divided into straight mineral oils, compounded oils for E.P. oils. Straight minerals oils without any additives are suitable only for light loads and hence are used for machining nonferrous metals like aluminum and magnesium.

(ii) Water soluble oils: Water soluble oils are blends of mineral oils, emulsifying agents, and coupling agents. For use these oils are mixed with water to form a water emulsion. Water provides the cooling effect and the oil is used for its lubricating properties.

(iii) Synthetic coolants: Synthetic coolants are non-petroleum products which are blended with water in the ratio of 50 to 250 parts of water for each part of the chemical. They have cooling properties better than soluble oils and are used chiefly for grinding.

(iv) Gaseous fluids: One of the major problems in cutting fluid application is the difficulty for the cutting fluid to actually reach the cutting zone during machining. The effectiveness of the cutting fluid can be considerably increased by supplying the cutting fluid in the form of a gas. Mist is the most commonly used gaseous fluid. In a mist cooling system, compressed air is used to atomize the coolant.

7.7.3 Selection of cutting fluids for different operations

The type of cutting fluid to be used depends upon the work material and the characteristics of the machining process. No single cutting fluid can be specified as the best of meet all requirements. The following general guide lines may be used.

a) Effect of work piece material

Cast Iron: Cast iron is generally cut without any cutting fluid. The graphite flakes in the structure of cast iron help in its easy machining. Sometimes cast iron is also cut with water soluble oils or using compressed air. The use of compressed air necessitates and exhaust system to remove the dust caused by blowing of fine iron particles.

Wrought iron: lard oil or water soluble oil

Steel: 1. Low and medium carbon steels: Water soluble oil

2.High carbon and nickel chromium alloy steel: Heavy duty soluble oils

Stainless steel: Heavy duty soluble oil or neat oil, with chlorine

Aluminium: Soluble oil or kerosene.

Brass, Bronze: Worked dry or with paraffin or lard oil.