Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 4. Physical characteristics of biomaterials: volume, density, specific gravity and surface area

In this lesson physical characteristics of biomaterials like volume, specific gravity and surface area and their methods of measurements are discussed. Their importance in handling, agro processing, storage and implications on the quality parameters are delineated.

4.1 INTRODUCTION:

Volume, density and specific gravity of food materials and agricultural products play an important role in many applications i.e. drying, storing, design of storage of mechanical compressing of ensilage, separation of undesirable material, determining the purity of seeds, separation and grinding maturity evaluations, for example texture and softer of fruits estimation of products, where their density increases with maturity. Volume, which affects consumer acceptance, can be calculated from the measured dimensions or by using various methods such as liquid, gas, or solid displacement methods and image processing. Volume measurement methods can also be used for measuring the density of solids. Volume/density can be expressed in different forms such as solid, apparent, and bulk volume/density depending on pores. Porosity is a physical property characterizing the texture and the quality of dry and intermediate moisture foods. Total porosity of particulate materials includes the voids within and among the particles. Porosity can be determined from the difference between bulk volume of a piece of porous material and its volume after destruction of all voids by compression, optical methods, density methods, or by using a pycnometer or porosimeter. Surface area measurement is required to estimate the pesticide application or weeding and other similar agricultural practices through image vision system. Surface area measurement can be done with planimeter, coating method, peeling method, and by image analysis.

4.2. Volume:

Volume is defined as the amount of three-dimensional space occupied by an object, usually expressed in units that are the cubes of linear units, such as cubic inches and cubic centimeters, or in units of liquid measure, such as gallons and liters. In the SI system, the unit of volume is m3.

4.2.1Apparent volume/ bulk volume: The volume of substance includes all pores within the material (internal pores) and also the void volume outside the boundary of individual particles when stacked in bulk (external pores). Bulk volume can be calculated by measuring the volume of the bulk sample by keeping the material in a container.

4.2.2. Solid volume/ True volume: This volume is the actual volume of the solid granular material, which devoid of the volume of internal pore space as well as intergranular spaces.

4.2.3. Expression and measurement of volume: Solid volume of solid material including water including any interior pores that are filled with air. It can be determined by gas displacement method, in which the gas is capable of penetrating all open pores up to the diamond of gas molecule.

\[volume\left( {{m^3}} \right) = \frac{{wt.ofdisplacedwater(kg)}}{{wt.densityofwater(kg/{m^3})}}\]

\[specificgravity = \frac{{wt.inair \times Sp.gravityofwater}}{{wt.ofdisplacedwater}}\]

Air comparison pycnometer:-

This is a commercially available instrument for volume measurement. The apparatus consist basically of two chambers and two pistons, a valve connecting the two chambers, a different pressure indicator, and a digital counter calibrated for readings in cubic centimeters. With the connecting valve closed any charge of the position of one piston must be duplicate by an identical stroke in the other in order to maintain the same pressure on each side of the differential pressure indicator. If the connecting valve is closed and both pistons are advanced the same amount to a given position, inserting a sample in the measuring chamber would cause a pressure differential which is brought to zero by withdrawing the piston in this chamber. Under this condition, the distance that the measuring piston differs from its position before inserting the sample will be proportional to the volume being measured. This instrument measures the true volume of a sample. For measurement of the apparent volume, i.e., the volume of the sample enclosed by its outer surface plus the volume of its open pores, the manufacturer recommends filling the pores first by immersing the sample in molten wax bath. Knowing the apparent and true volume of sample, the open-pore volume can be calculated as an index of porosity.

Pycnometer Method:

For seeds and grains, the method of specific gravity bottle or pycnometer and toluene has been the practice for many years. Toluene has the advantages of (1) Little tendency to soak into kernel;(2) a low surface tension, enabling it to flow smoothly over the kernel surface;(3) little solvent action on constituents of the kernel especially fats and oils;(4) a fairly high boiling point;(5) not changing its specific gravity and materially on exposure to the atmosphere; and (6) having a low specific gravity.

Gas expansion pycnometer is also known as constant volume gas pycnometer. The simplest type of gas pycnometer (due to its relative lack of moving parts) consists of two chambers, one (with a removable gas-tight lid) to hold the sample and a second chamber of fixed, known (via calibration) internal volume – referred to as the reference volume or added volume. The device additionally comprises a valve to admit a gas under pressure to one of the chambers, a pressure measuring device – usually a transducer – connected to the first chamber, a valved pathway connecting the two chambers, and a valved vent from the second of the chambers. In practice the sample may occupy either chamber that is gas pycnometers can be constructed such that the sample chamber is pressurized first, or such that it is the reference chamber that starts at the higher pressure. Various design parameters have been analyzed by Tamari.[4] The working equation of a gas pycnometer wherein the sample chamber is pressurized first is as follows:

V= Vc + Vs /[1-p1/p2]

where Vs is the sample volume, Vc is the volume of the empty sample chamber (known from a prior calibration step), Vr is the volume of the reference volume (again known from a prior calibration step), P1 is the first pressure (i.e. in the sample chamber only) and P2 is the second (lower) pressure after expansion of the gas into the combined volumes of sample chamber and reference chamber.

Variable volume pycnometer (or gas comparison pycnometer) consists of either a single or two variable volume chambers. The volume of the chamber(s) can be varied by either a fixed amount by a simple mechanical piston of fixed travel, or continuously and gradually by means of a graduated piston. Resulting changes in pressure can be read by means of a transducer, or nullified by adjustment of a third ancillary, graduated variable-volume chamber.

4.3. Density (r):

Bulk Density (rb): It is the density of material when stacked or packed in bulk. Bulk density of the material is determined by dividing the material volume inclusive of voids to weight of product. There are two kinds of voids, voids between particles and void within particles. The bulk density is an important in packaging requirement and is often 2-20% of true density

Tapped Bulk Density: Tap bulk density is measured for powdery samples. The volume is measured after tapping the powdery material so that the product is adjusted to intergranular spaces, but it cannot eliminate all the intergranular spaces.

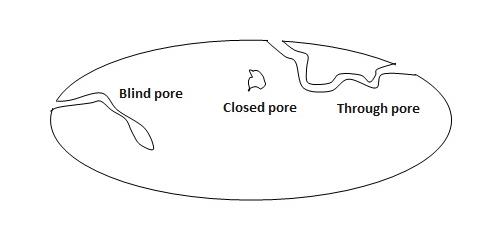

Particle density / true density (rp): Density of solid material constituting the true volume of the occupied by the material, excluding any interior pores that are filled with air (blind and through pores). It can be calculated by dividing the sample weight by solid volume determined by the gas displacement method in which inert gas is capable of penetrating all open pores up to the diameter of the gas molecule. Gas displacement method is employed to find out the particle density. In gas displacement method, helium enters every nook and corner of material being lighter and inert gas.

Solid/substance density: is the density of a material measured when the material has been broken into pieces small enough to be sure that no closed pores remain.

Solid/substance density: is the density of a material measured when the material has been broken into pieces small enough to be sure that no closed pores remain.

Apparent Density: Apparent density (ρapp) is the density of a substance including all pores within the material (internal pores). Apparent density of regular geometries can be determined from the volume calculated using the characteristic dimensions and mass measured. Apparent density of irregularly shaped samples may be determined by solid or liquid displacement methods.

Solid displacement method:

Liquid displacement method:

Gas displacement method:

Image vision system:

Mercury displacement is used to find out as mercury cannot enter the small inters-particles pores because of its high density and surface tension and does not wet the surface.

4.4. Porosity: (inter granular space)

It is the measure of void space between the materials.

It is defined on the percentage of volume of inter grain space to the total volume of grain bulk.

Porosity depends on-

Shape

Dimension/Size

Roughness of grain surface

\[Porosity\left(\varphi\right)=1\]\[-\frac{{bulkdensity}}{{truedensity}}\]

Method of measurement:

Quality of food materials can be assessed by measuring their densities. Density data is required in separation process, such as centrifugation, sedimentation, hydraulic transport, for liquid, pumping power calculation.

Specific gravity balance: For, smaller objects such as small fruits, peas and beans, kernels of corns, etc., an analytical balance or more conveniently a specific gravity balance can be used to determine volume, density, and specific gravity employing the following expressions.

Sp. Gravity balance= volume =\[\frac{{wt.inair \times wt.inwater}}{{wt.densityofwater}}\]

Sp. Gravity =\[\frac{{wt.inair}}{{wt.inair - wt.inwater}} \times Sg.ofwater\]

=\[\left[ {\frac{{wa.object}}{{\left( {wa - ww} \right)both - \left( {wa - ww} \right)\sin \ker }}} \right] \times Sg.ofwater\]

D= diameter of a sphere having volume equal to that of a grain Cv=(wt./density)

d = diameter of a sphere found by taking the geometric mean of the 3 mutually perpendicular measured seed dimension

davg =Average of maximum & minimum diameter of the fruit.

Specific gravity gradient tube:

Water = 997.T3+3.143910-3 T-3.757410-3 T2

CHO = 1599.1 - 0.31046T

Protein = 1330 - 0.5148T

Fat = 925.59 – 0.41754T

Ash = 2423.8 – 0.28063T

Ice = 916.89 – 0.1307T

4.5. Surface area:

Knowledge of surface area of some parts of plant materials, such as leaf area and surface area of fruits, is important to plant scientist as well as engineers handling and processing the products. Leaf area is an indicator of photosynthetic capacity and growth rate of a plant and its measurement is of value in studies of plants competition for light and nutrients, plant-soil-water relations, determining application rates of insecticides and fungicides. In crop like tobacco, where the leaf is the major commercial product, leaf area is a good indicator of yield potential. Likewise, surface areas of fruits are important in investigation related to spray coverage, removal of spray residues, respiration rate, light reflectance and color evaluation, and heat transfer studies in heating and cooling processes.

Fig: planimeter

Leaf and stalk surface area: Some of the methods used for measuring leaf and stalk surface area are contact printing the surface on light sensitive paper and measuring the area by a planimeter; tracing the area on a graph paper and counting the squares; use of photographic projector similar to the method described for seeds and grains; light interception method and the use of photronic cell to measure the intercepted light ; use of an air flow planimeter which measure the area of a function of the surface obstructing the flow of air and a measurement of length and width of a leaf and relating these measurements to the area of the leaf.

Fruit surface area: For measurement of surface areas of fruits, the fruit is peeled in narrow strips and the planimeter sum of the areas of tracing of the strips taken as the surface area of the fruit.

Specific Surface by the Coating Method: The specific area of a number of grains may be determined by coating the grains with a single layer of metal powder and measuring the change in weight. A control group, consisting of geometric shapes of known surface area and of a density close to the grain being tested, is run through the coating process with the grain. A factor representing the coating weight per unit surface area for the control group is used to calculate the surface area of the grain. The bulk volume of the grain sample is measured and entered into the calculation of specific surface along with the calculated surface area.

Selected references:

Mohsenin, N.N. 1986. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach Science Publishers: New York

Moreda, G.P., Ortiz-Cañavate, J., García-Ramos, F.J. & Ruiz-Altisent, M. (2009). Non-destructive technologies for fruit and vegetable size determination – a review. Journal of Food Engineering 92 119–136

Sahin S. & Sumnu, S. G. 2006. Physical Properties of Foods. Springer, USA