Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 31. Food Safety Management System-Iso 22000:2005

31.1 Introduction:

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is carried out through ISO technical committees.

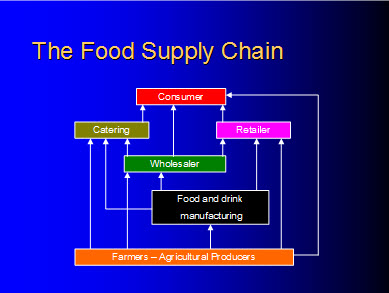

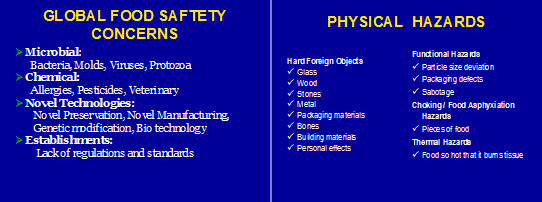

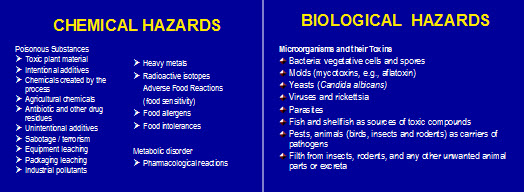

Food safety is related to the presence of food-borne hazards in food at the point of consumption. As the food safety hazards can occur at any stage of the food chain, adequate control throughout the food chain is essential. Thus, food safety is ensured through the combined efforts of all the parties participating in the food chain.

The International Standard ISO 22000:2005 specifies the requirements for a food safety management system that combines the following generally recognized key elements to ensure food safety along the food chain, up to the point of final consumption:

The International Standard integrates the principles of the Hazard Analysis and Critical Control Point (HACCP) system and application steps developed by the Codex Alimentarius Commission. By means of auditable requirements, it combines the HACCP plan with prerequisite programmes (PRPs). Hazard analysis is the key to an effective food safety management system, since conducting a hazard analysis assists in organizing the knowledge required to establish an effective combination of control measures.

Since ISO 22000 is a generic food safety management standard, it can be used by any organization directly or indirectly involved in the food chain. It applies to all organizations in the food chain. It doesn't matter how complex the organization is or what size it is, ISO 22000 can help ensure the safety of its food products.

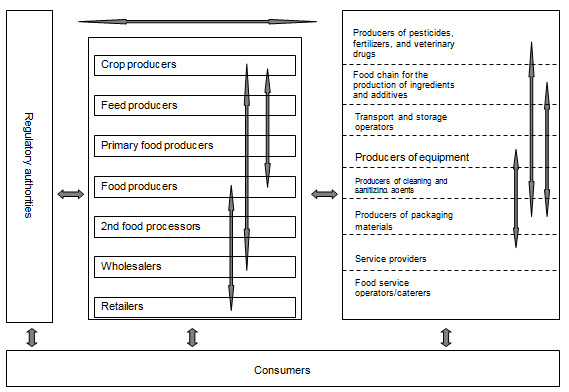

The food chain consists of the entire sequence of stages and operations involved in the creation and consumption of food products. This includes every step from initial production to final consumption. More precisely, it includes the production, processing, distribution, storage, and handling of all food and food ingredients.

The food chain also includes organizations that do not directly handle food. These include organizations that produce feed for animals. It also includes organizations that produce materials that will eventually come into contact with food or food ingredients.

31.1.1 Advantages of ISO 22000: 2005

ISO 22000 will help you to achieve the following objectives:

a) To establish a food safety management system (FSMS).

b) To ensure that products do not cause adverse health effects.

c) To demonstrate compliance with external safety requirements.

d) To evaluate customers' food safety requirements.

e) To provide safe products and enhance customer satisfaction.

f) To export food products and penetrate international markets.

g) To communicate safety issues throughout the food chain.

h) To ensure compliance with company’s food safety policy

31.2 Key Elements of ISO 22000:

-

Interactive communication: Communication is essential along the food chain to ensure all relevant food safety hazards are identified and adequately controlled at each step within the food supply chain. This implies for both upstream and down steam in organizations.

-

System Management: The most effective food safety systems are to be designed, operated within the framework of structured management system then and incorporated into the overall management activities of the organization.

-

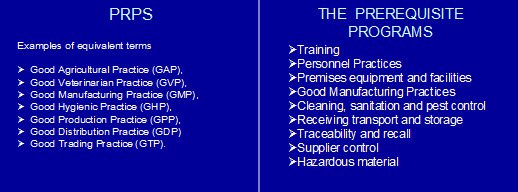

Prerequisite Program: The prerequisite programmes are classified into 2 subcategories. The Infrastructure and Maintenance programs which cover permanent features in food safety. The Operational prerequisite programs are designed to reduce the risk of hazards in the product or processing environment.

-

HACCP Principles: The HACCP plan is used to manage the critical control points determined to eliminate, prevent or reduce specific food safety hazard from the product, as determined during hazard analysis.

Interactive Communication

ISO 22000 requires that interactive communication (i.e. proactive, open, continuous

dialogue with the stake holders to ensure that:

a) all relevant food safety hazards are identified and adequately controlled at each step within the food chain through communication to all parties in the food chain.

b) Communication with customers and suppliers, based on the information

generated through systematic hazard analysis is maintained to establish customer and supplier requirements in terms of feasibility, need and impact on the end product.

31.3 Prerequisite Programme

Prerequisite programs (PRPs) are the conditions that must be established throughout the food chain and the activities and practices that must be performed in order to establish and maintain a hygienic environment. PRPs are also referred to as good hygienic practices, good agricultural practices, good production practices, good manufacturing practices, good distribution practices, and good trading practices.

Operational prerequisite programs (OPRPs) are prerequisite programs (PRPs) that are essential. They are essential because a hazard analysis has shown that they are necessary in order to control specific food safety hazards.

31.4HACCP Principles

ISO 22000 integrates the HACCP 7 principles developed by the Codex Alimentarius Commission and dynamically combine it with PRPs necessary to control and reduce any food safety hazards identified for the end products delivered to the next step in the food chain to acceptable levels.

HACCP PRINCIPLES

1. Conduct a hazard analysis;

2. Determine the Critical Control Points (CCP’s);

3. Establish critical limit(s);

4. Establish a system to monitor control of the CCP;

5. Establish the corrective action to be taken when monitoring indicates that a particular CCP is not under control;

6. Establish procedures for verification to confirm that the HACCP system is working effectively; and

7. Establish documentation concerning all procedures and records appropriate to these principles and their applications

31.5 ISO 22000 Food Safety Management System

FSMS is a set of interrelated to establish policy and objectives and to achieve those objectives used to direct and control an organization with regard to food safety.

An effective FSMS should be well-established, documented, implemented, maintained and continually improved / updated and has its products / services that actually meet its intended usage and are safe and is proactive and innovative, scientific, risk-avoiding and prevention-oriented

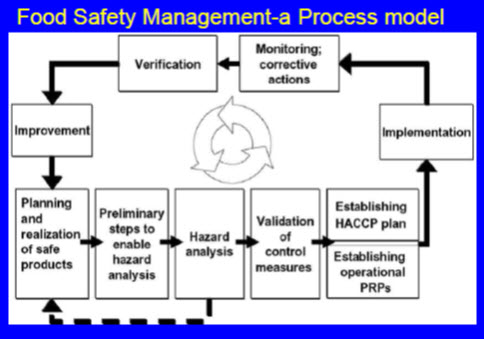

Model of the ISO 22000

The ISO 22000 model is a continuous improvement process-based FSMS with systematic approach to developing, planning, validating, establishing, implementing, monitoring, verifying and improving the FSMS.

Fig Food Safety Management-a Process model

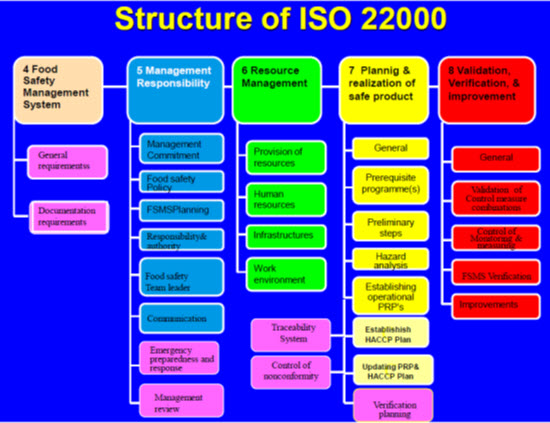

Key Requirements of the ISO 22000: 2005

The ISO 22000 standard is a management system standard that sets requirements for results without setting requirements for resources. This standard sets out specific requirements for the five areas shown in the fig.08).

Clause wise requirements of ISO 22000

Implementation model for food safety control measures

ISO 22000 requires that organizations to plan and develop processes needed for realization of safe product, implement, operate and ensure effectiveness of planned activities. This includes PRP’s, Operational PRP’s and/or HACCP plan.The organization uses a dynamic and systematic process approach to develop the food safety management system. This is achieved through effective development, implementation, monitoring of planned activities, maintenance and verification of control measures, updating the food processes and process environment, and through appropriate actions in the event of the production of nonconformities.

ISO 22000 groups control measures into three groups( See Fig 10):

i) Prerequisite programmes (PRPs) that manage the basic conditions and activities; the PRPs are not selected for the purpose of controlling specific identified hazards but for the purpose of maintaining a hygienic production, processing and/or handling environment;

ii) Operational prerequisite programmes (OPRPs) that manage those control measures that the hazard analysis identifies as necessary to control identified hazards to acceptable levels, and which are not otherwise managed by the HACCP plan; and

iii) HACCP plan to manage those control measures that the hazard analysis identifies as necessary to control identified hazards to acceptable levels, and which are applied at critical control points (CCP’s).

FOOD SAFETY MANAGENT SYSTEM PLAN

CONSTITUTION OF A MULTIDISCIPLINARY FOOD SAFETY TEAM

Gathering information for prerequisites

Gathering information for hazard analysis

1. Recommended International Code of Practice General Principles of FoodHygiene(Codex)

1. Product characteristics

a) Raw materials, ingredients and product-contact materials

b) Characteristics of end products

2. Industry specific guidelines /codes

2. Intended use

3. Statutory & regulatory requirements in that specific area

3. Flow diagrams, onsite verification.

Process steps and control measures

ISO 22000 Certification

ISO 22000 is designed to be used for certification/registration purposes. In other words, once company has established a FSMS that meets ISO's requirements, it can apply for certification to a certification agency to audit the system. If certification agency find after audit that the implemented system meets the ISO 22000 requirements, it will issue an official certificate that states that company’s FSMS meets the food safety requirements.

However, it is not mandatory to go for certification. A company can be in compliance without being formally certified by an accredited certification agency. It can self assess the system implemented and declare ISO 22000 compliant company. But company customers and business partners are not likely to accept that the company has an effective FSMS if it is not certified.

Benefits of ISO 22000 for users

Organizations implementing the standard will benefit from:

-

Organized and targeted communication among trade partners ;

-

Optimization of resources (internally and along the food chain);

-

Improved documentation;

-

Better planning, less post process verification;

-

More efficient and dynamic control of food safety hazards;

-

All control measures subjected to hazard analysis;

-

Systematic management of prerequisite programmes;

-

Wide application because it is focused on end results;

-

Valid basis for taking decisions;

-

Increased due diligence;

-

Control focused on what is necessary, and

-

Saving resources by reducing overlapping system audits