Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Lesson.12 Methods of Drying

Foods are dried using several methods falling into various categories. The drying methods being used for foods

along with the process parameters are given in Table 3. It can be observed from the table that sun/solar drying, hot air, osmotic dehydration, microwave assisted drying, infra-red, freeze, vacuum and hybrid drying are most commonly used methods for majority of the foods. The foregoing sections illustrate these methods of food drying.

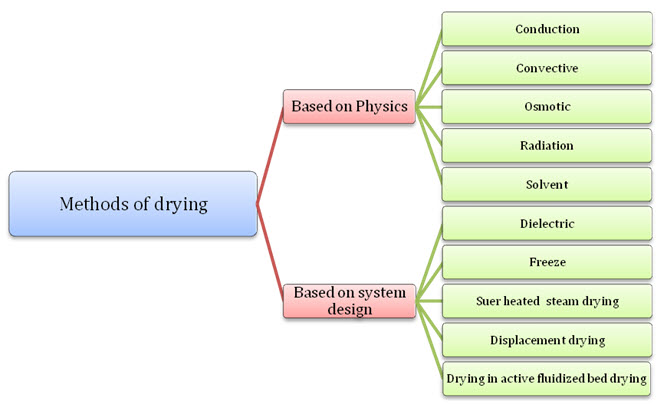

Figure 2: Chart showing the classification of dryers based on methods of drying

Hot air drying

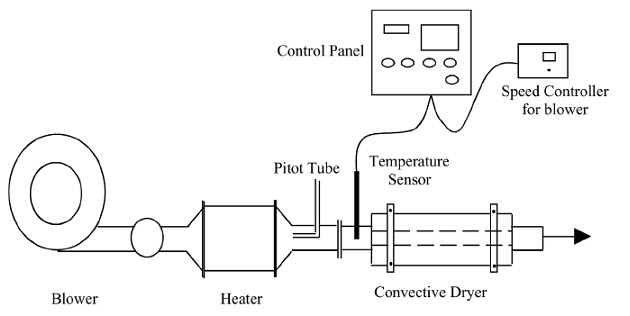

The hot air dryer is used to dry several fruits and vegetables and biomaterials. Heating ambient air to use for drying, a simple cost-effective procedure. Increase in the air temperature decreases the humidity of air which makes favourable conditions to increase the surface mass transfer during drying. A typical hot air dryer consists of a cabinet with fitted blower, speed regulator, temperature controller, heaters and humidity sensing device. The product is generally The relative humidity and temperature of the ambient air were in the range 60–65% and 30°C, respectively. The typical setup of HAD is shown in Fig. 1.

FIG. 1. Hot air dryer (HAD) set up for dehydration.

Heat Pump Dryer

High temperature drying deteriorates the material structure and can render it unsuitable for further use. Low temperature drying of specialty crops reduces the risk of loss in nutrient content and damage to physical properties. Drying system incorporating a dehumidification cycle have been developed that both conserve energy and handle the material gently. The dryer operates using a heat pump where both sensible and latent heats are recovered from the exhaust air. The heat is then recycled back through the dryer by heating the air entering the dryer. The heat pump drying system is a combination of two sub-systems: a heat pump and a dryer.

The heat pump operates according to a basic air conditioning cycle involving four main components: the evaporator, the compressor, the condenser and the expansion valve.

The working fluid (refrigerant) at low pressure is vaporized in the evaporator by heat drawn from the dryer exhaust air. The compressor raises the enthalpy of the working fluid of the heat pump and discharges it as superheated vapor at high-pressure. Heat is removed from the working fluid and returned to the process air at the condenser. The working fluid is then throttled to the low-pressure line (using an expansion valve) and enters the evaporator to complete the cycle.

In the dryer system, hot and dry air at the exit of condenser is allowed to pass through the drying chamber where it gains latent heat from the material. The humid air at dryer exit then passes through the evaporator where condensation of moisture occurs as the air goes below dew point temperature.

A performance study of a heat pump dryer system is required to fully understand its operating characteristics based on different materials to be dried. To accomplish this objective, the project was divided into three tasks (steps). Task A is concerned with the design and construction of a prototype heat pump dryer system. Task B involves field-testing of a prototype system using specialty crops or material with similar characteristics. Finally, task C is to develop a comprehensive computer model using the fundamentals of thermodynamics for a heat pump dryer system and to determine its accuracy compared to experimental results.

Sun/Solar drying

Sun drying is common method to preserve the root products in tropical countries. Sun drying consists of direct and indirect drying. Open sun drying is considered as direct sun drying process. It is generally used in the developing and undeveloped countries and carried out by spreading foods either on the floor or on supporting structures made from locally available material like wood, bamboo etc. However, this technique is extremely weather dependent and has the problems of contamination with dust, wind-blown debris, sand particles and environmental pollution, insect infestation, damage to the product by rodents, birds and animals, growth of microorganisms and additional losses during storage due to insufficient or non-uniform drying. Also, degradation through exposure to direct irradiation of the sun and to rain, storm and dew takes place as well as the required drying time can be quite long. Losses during open sun drying can be estimated at more than 30% and could be reduced to a great extent by improved methods of solar drying. Therefore, indirect method of sun drying that is use of solar assisted mechanical dryers, which are far more rapid, providing uniformity and hygiene, are inevitable for root drying processes. The literature shows that most of the fruit and vegetables can be dried using indirect type of solar drying with drying time from few hours to 5 days depending upon the product to be dried.

Disadvantages of Open Sun Drying

-

Damage to the product by rodents, birds and animals

-

Degradation through exposure

-

Contamination

-

Insect infestation

-

Growth of microorganisms

-

Insufficient or non-uniform drying

-

Losses > 30%

Main Parts of Solar Dryers

-

Drying cabinet, where the material to be dried is placed and where the drying takes place

-

Collector to convert solar radiation into heat

-

Means for keeping the drying air in flow

-

Ducts, pipes, and other appliances

-

Measuring and control equipment

-

Auxiliary energy source (optional)

-

Heat transfer equipment for transferring heat to the drying air or to the material (optional)

-

Heat storage unit (optional).

Classification of Solar Dryers

-

solar dryers can be classified on the basis of energy sources used in to following types:

1. Solar natural dryers using ambient energy sources only.

2. Semiartificial solar dryers with a fan driven by an electric motor for keeping a continuous air flow through the drying space.

3. Solar-assisted artificial dryers able to operate by using a conventional (auxiliary) energy source if needed.

FIG. 1. Schematic diagram and photograph of a solar cabinet dryer.

1. Inlet from atmosphere; 2. control valve for inlet air; 3. duct carrying atmospheric air to the collector panels; 4. solar collector panel; 5. duct carrying heated air from collector panels to the blower; 6. blower; 7. drying cabinet; 8. control valve for hot air dryer outlet.