Site pages

Current course

Participants

General

Module 1. Micro-irrigation

Module 2. Drip Irrigation System Design and Instal...

Module 3. Sprinkler Irrigation

Module 4. Fertigation System

Module 5. Quality Assurance & Economic Analysis

Module 6. Automation of Micro Irrigation System

Module 7. Greenhouse/Polyhouse Technology

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 20. Fertilizers Application Methods

Fertilizers are substances containing chemical elements that improve the growth of plants. They give nutrition to the crops. Fertilizers do not only assist in increasing yields but also promote healthy growth and development of plants. They contain nitrogen which acts as a growth booster which can be characterized by the green color of plants. Phosphorus substance in fertilizers aids in the faster formation of seeds and root development. In order to get maximum benefit from manures and fertilizers, they should not only be applied in proper time and in right manner but any other aspects should also be given careful consideration. Different soils react differently with fertilizer application. Similarly, the N, P, K requirements of different crops are different and even for a single crop the nutrient requirements are not the same at different stages of growth.

Theses fertilizers are available in solid granules and are fully soluble or partially soluble. Fertilizers are also available in liquid form. The modes of application solid and liquid fertilizers differ.

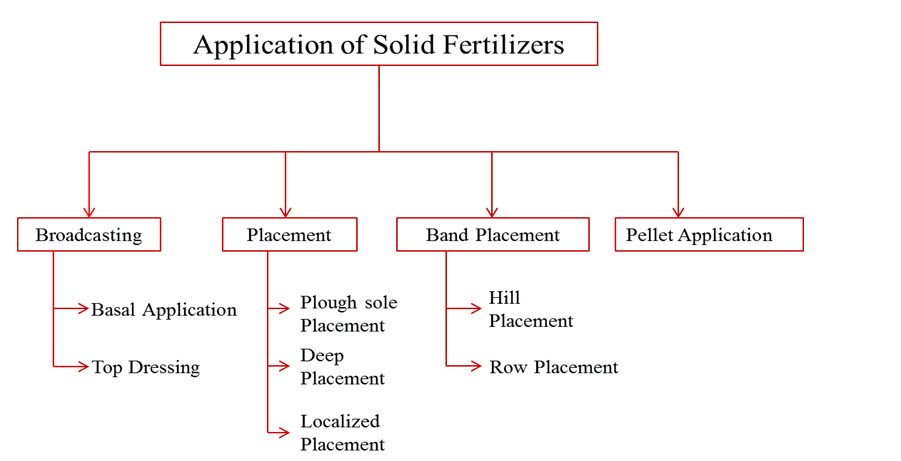

20.1 Solid Fertilizers Application Methods

The different methods of solid fertilizer application are shown through the following classification chart.

20.1.1 Broadcasting

The broadcasting refers to spreading fertilizers uniformly all over the field. It is suitable to crops with dense stand, the plant roots permeate the whole volume of the soil. Normally broadcasting increases application of high doses. Insoluble phosphatic fertilizers such as rock phosphate are used in this method of application. The broadcasting of fertilizers is of two types.

a) Broadcasting at sowing or planting (Basal application)

The main objectives of broadcasting the fertilizers at sowing time are to uniformly distribute the fertilizer over the entire field and to mix it with soil.

b) Top dressing

It is the broadcasting of fertilizers particularly nitrogenous fertilizers in closely sown crops like paddy and wheat, with the objective of supplying nitrogen in readily available form to growing plants.

Disadvantages of broadcasting

The main disadvantages of application of fertilizers through broadcasting are:

i) Nutrients cannot be fully utilized by plant roots as they move laterally over long distances.

ii) The weed growth is stimulated all over the field.

iii) Nutrients are fixed in the soil as they come in contact with a large mass of soil.

20.1.2 Placement

It refers to the placement of fertilizers in soil at a specific place with or without reference to the position of the seed.

Placement of fertilizers is normally recommended in small quantity of fertilizers application. Due to poor root development and low soil fertility and Phosphatic and Potassic fertilizer requirements, this method is preferred.

The most common methods of placement are as follows:

a) Plough sole placement

In this method, fertilizer is placed at the bottom of the plough furrow in a continuous band during the process of ploughing.

Every band is covered as the next furrow is turned.

This method is suitable for areas where soil becomes quite dry upto few centimeters below the soil surface and soils having a heavy clay pan just below the plough sole layer.

b) Deep placement

It is the placement of ammoniacal nitrogenous fertilizers in the reduction zone of soil particularly in paddy fields, where ammoniacal nitrogen remains available to the crop. This method ensures better distribution of fertilizer in the root zone soil and prevents loss of nutrients by runoff.

c) Localized placement

It refers to the application of fertilizers into the soil close to the seed or plant in order to supply the nutrients in adequate amounts to the roots of growing plants. The common methods to place fertilizers close to the seed or plant are as follows:

Drilling:

In this method, the fertilizer is applied at the time of sowing by means of a seed-cum-fertilizer drill. This places fertilizer and the seed in the same row but at different depths. Although this method has been found suitable for the application of Phosphatic and Potassic fertilizers in cereal crops, but sometimes germination of seeds and young plants may get damaged due to higher concentration of soluble salts.

Side dressing:

It refers to the spreading of fertilizer in between the rows and around the plants. The common methods of side dressing are:

1) Placement of nitrogenous fertilizers by hand in between the rows of crops like maize, sugarcane, cotton etc., to apply additional doses of nitrogen to the growing crops and

2) Placement of fertilizers around the trees like mango, apple, grapes, papaya etc.

20.1.3 Band placement

If refers to the placement of fertilizer in bands. There are two types of band placement of fertilizer and these are stated below:

a) Hill placement

It is practiced for the application of fertilizers in orchards. In this method, fertilizers are placed close to the plant in bands on one or both sides of the plant. The length and depth of the band varies with the nature of the crop.

b) Row placement

When the crops like sugarcane, potato, maize, cereals etc., are sown close together in rows, the fertilizer is applied in continuous bands on one or both sides of the row, which is known as row placement. Fig. 20.1 shows the row placement of fertilizer.

20.1.4 Pellet application

-

It refers to the placement of nitrogenous fertilizer in the form of pellets 2.5 to 5 cm deep between the rows of the paddy crop.

-

The fertilizer is mixed with the soil in the ratio of 1:10 and made small pellets of convenient size to deposit in the mud of paddy fields.

(Source:http://agritech.tnau.ac.in/agriculture/agri_nutrientmgt_methodsoffertilizerappln.html)

(Source:http://agritech.tnau.ac.in/agriculture/agri_nutrientmgt_methodsoffertilizerappln.html)

The main advantages are as follows:

i) When the fertilizer is placed, there is minimum contact between the soil and the fertilizer, and thus fixation of nutrients is greatly reduced.

ii) The weeds all over the field cannot make use of the fertilizers.

iii) Residual response of fertilizers is usually higher.

iv) Utilization of fertilizers by the plants is higher.

v) Loss of nitrogen by leaching is reduced.

vi) Being immobile, phosphates are better utilized when placed.

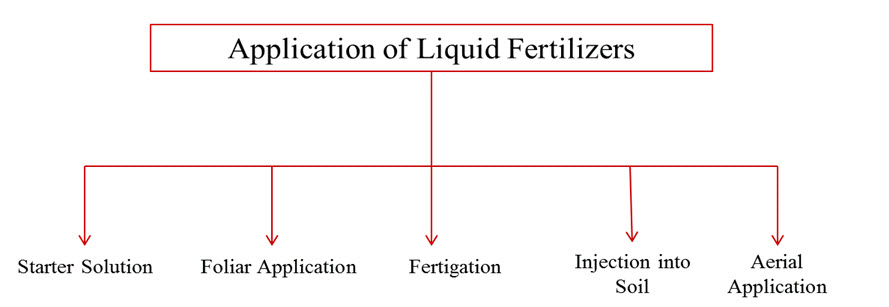

20.2 Liquid fertilizers application methods

Liquid fertilizers and water soluble granular fertilizers can be applied in different ways. These methods are shown through following classification chart.

20.2.1 Starter solutions

It refers to the application of solution of N, P2O5 and K2O in the ratio of 1:2:1 and 1:1:2 to young plants at the time of transplanting particularly for vegetables. Starter solution helps in rapid establishment and quick growth of seedlings.

The disadvantages of starter solutions are

(i) Extra labour is required, and

(ii) The fixation of phosphate is higher.

20.2.2 Foliar application

It refers to the spraying of fertilizer solutions containing one or more nutrients on the foliage of growing plants.

Several nutrient elements are readily absorbed by leaves when they are dissolved in water and sprayed on them.

The concentration of the spray solution has to be controlled; otherwise serious damage may result due to scorching of the leaves.

Foliar application is effective for the application of minor nutrients like iron, copper, boron, zinc and manganese. Sometimes insecticides are also applied along with fertilizers.

20.2.3 Injection into soil

Liquid fertilizers for injection into the soil may be of either pressure or non-pressure types.

Non-pressure solutions may be applied either on the surface or in furrows without appreciable loss of plant nutrients under most conditions.

Anhydrous ammonia must be placed in narrow furrows at a depth of 12-15 cm and covered immediately to prevent loss of ammonia.

20.2.4 Aerial application.

In areas, where ground application is not practicable, the fertilizer solutions are applied by aircraft particularly in hilly areas, forest lands, grass lands, sugarcane fields etc. In this method considerable amount of fertilizer is lost. In a very special case this method is adopted.

20.2.5 Fertigation

The combined application water soluble solid or liquid fertilizers with irrigation water through pressurized irrigation system is known as fertigation. Generally nitrogenous fertilizers such as urea and other ammoniatic fertilizers easily water soluble are applied along with irrigation water. The fertigation increases yield minimizes soil and water pollution. This also saves fertilizers. Therefore, it saves foreign revenue, as these fertilizers are expensive and imported from other countries.

20.3 Methods of Fertigation

Three principal methods are used for the injection of fertilizers or soluble chemicals into the micro-irrigation system.

Pressure Differential

The Venturi (vacuum)

Injection pump

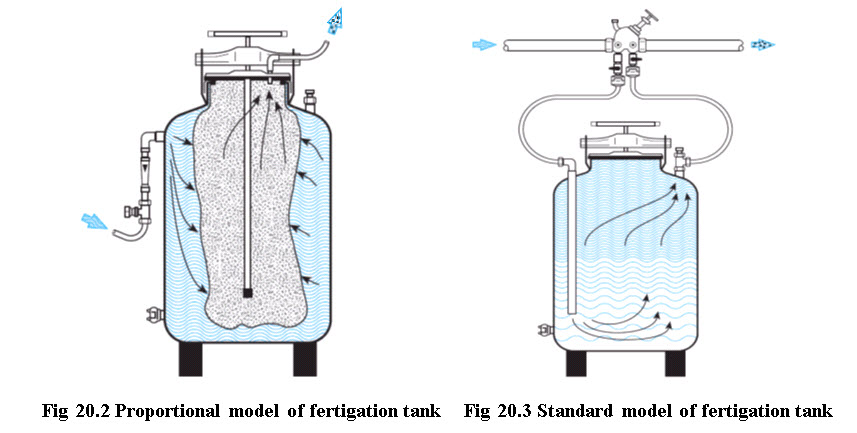

20.3.1 Pressure Differential

In the pressure differential system, the tank is under pressure (usually main line pressure). A pressure difference is created by a valve and pressure regulator between the tank inlet and outlet. The difference in pressure between the connection and the constriction in pipe is sufficient to cause the flow of water through the tank under pressure. A gradient of 0.1 to 0.2 bars (1 to 2 m) is required to redirect an adequate stream of water through a connecting tube of 9-12 mm diameter. A sealed airtight pressure supply tank is required to withstand maximum operating pressure. Precise control valves are necessary to maintain a preset injection rate. The pressure differential device is cheap and simple. A wide dilution ratio can be attained with no source of external source of energy.

The nutrient cannot be precisely regulated prior to each application, the tank has to be refilled with fertilizer. Valve throttling generates pressure losses, and the system is not straight forward automated. Two types of fertilizer tanks shown through Figs. 20.2 and 20.3 are generally used in this method.

Proportional models are generally vertical tanks with the size varies from 10 to 300 litres. Quantitative models are: 5, 30, 60, 90, 120 L of capacity (vertical tanks) and 120, 220 litres (horizontal tanks).

Fertilizer tanks are made up of mild steel. These tanks are powder coated with more than 70 micron thick deep blue colored epoxy-polyester from both inside and outside surface for protection against corrosion and weather effects. Normally fertilizer tanks have a 100 micron protective coating of extra durable polyester applied electrostatically and oven cured on a zinc-phosphate layer for maximal anti-corrosion protection.

(Source: http://www.odis.co.il)

20.3.2 Venturi Injection Method

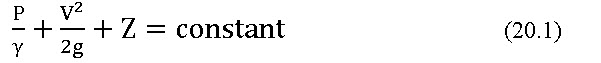

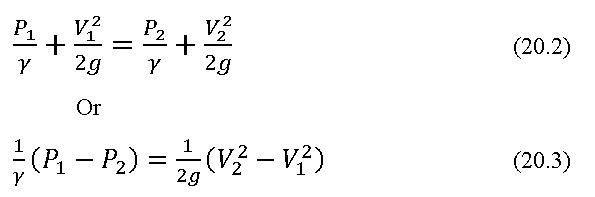

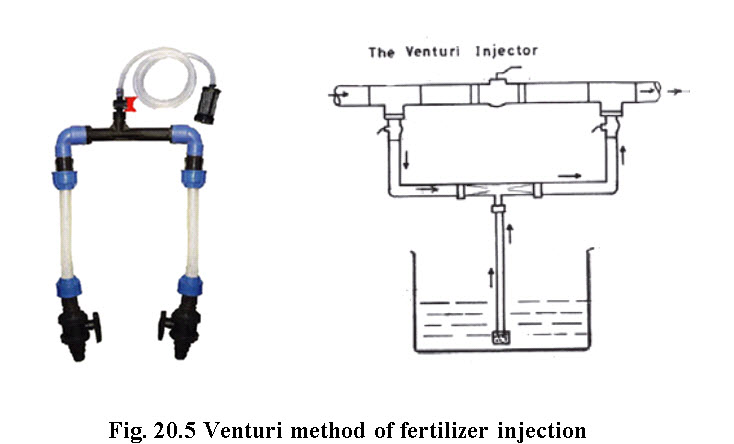

Suction of the fertilizer solution is generated by water flow through a constricted passageway. The high flow velocity of water in the constriction reduces water pressure below atmospheric pressure so that the fertilizer solution is sucked from an open tank in to the constriction through a small diameter tube. The process of injection of fertilizer solution can be explained by Bernoulli’s principle, assuming inlet and outlet ports of venturi are at same elevation and total energy at a point is constant. This can be given by energy equation

where P = Pressure, V = Velocity, Z = Elevation, γ = unit weight of water g = acceleration due to gravity.

Considering inlet and outlet ends of a venturi injector are as points 1 and 2 respectively and they are located at same elevations, therefore Z1=Z2. The equation (20.1) becomes

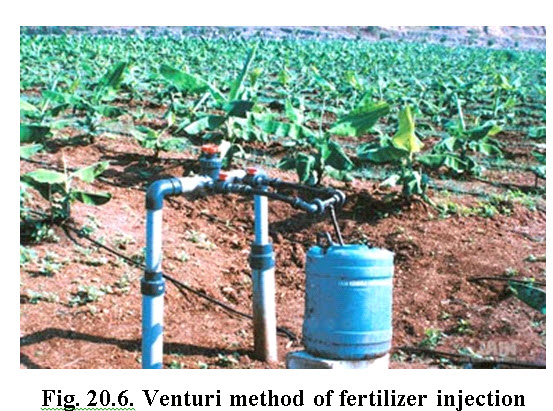

The change in velocity V2 from V1 due to constriction in venturi pipe diameter causes suction (change in pressure from P1 to P2) below atmospheric pressure, thereby suction of fertilizer solution. Figure 20.5 explains the principle of operation of a venturi injector. Fig. 20.6 shows use of venturi injector for application of fertilizer in banana field.

(Source: ftp://ftp.fao.org/docrep/fao/010/a1336e/a1336e16.pdf)  (Source: www.jains.com)

(Source: www.jains.com)

Advantages

Very simple to operate, no moving parts.

Easy to install and to maintain.

Suitable for very low injection rates.

Injection can be controlled with a metering valve.

Suitable for both proportional & quantitative fertilization.

Disadvantages

1. Creates considerable pressure loss in irrigation pipe line and sometimes a booster pump is required.

2. Quantitative fertigation is difficult.

3. Automation is difficult

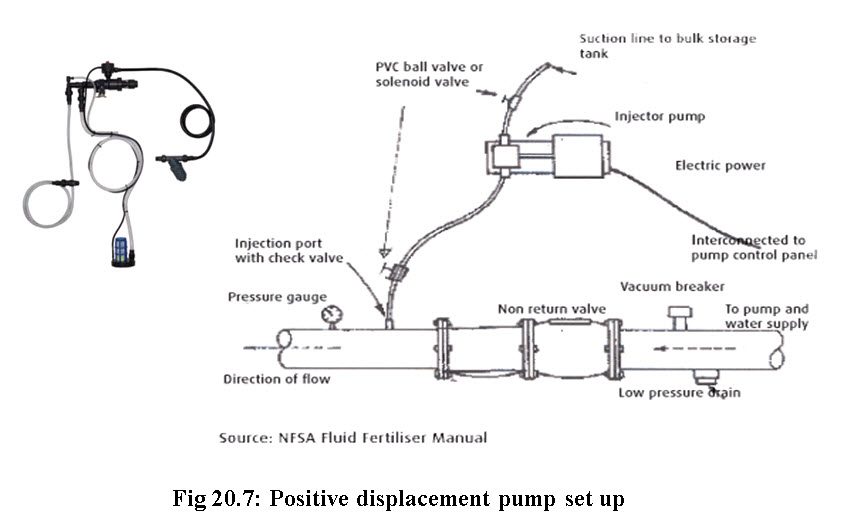

20.3.3 Fertilizer Injection Pump

In this method a pump is used to lift the fertilizer stock solution from the storage tank and inject it under pressure in a pipe carrying irrigation water. The injection rate can be set to create a desirable mixing ratio. The fertilizer solution is normally pumped from an unpressurised storage tank.

Pumping is a common method of injecting fertilizer into a drip irrigation system. Fertilizer pumps are driven by electricity, internal combustion engines, tractor PTO or hydraulically the inherent water pressure in the irrigation system. Hydraulic pumps are versatile reliable and low operation and maintenance costs. A diaphragm or piston movement injects the fertilizer solution into the irrigation system. Positive injection pumps include single or multiple piston pumps, diaphragm pumps, gear pumps, and roller pumps. Where two or more different types of fertilizers are required, multiple pump units can be used to avoid or reduce precipitation problems. All of the injection pumps can be regulated to achieve the desired rate of application, usually by adjusting the length of stroke of the piston pump or by selecting the appropriate pulley diameter. Another means of adjusting fertilizer application is with variable-speed motors. The system should flush itself with clean water at least once after injecting the fertilizer solution. The major advantages of the system are flexibility and high discharge rate, the system does not add to the head loss in a pressurized irrigation system and that it maintains a constant concentration of nutrients throughout the period of fertilizer application. High equipment cost and high operation and maintenance costs (Michael, 2010) are the limitations of this method of fertigation.

(Source: ftp://ftp.fao.org/docrep/fao/010/a1336e/a1336e16.pdf)

References:

Michael, A.M. (2010). Irrigation Theory and Practice, 2nd Edition, 2010, Vikas Publishing House Pvt. Ltd, Noida, U.P.

ftp://ftp.fao.org/docrep/fao/010/a1336e/a1336e16.pdf

ftp://ftp.fao.org/docrep/fao/010/a1336e/a1336e16.pdf

http://agritech.tnau.ac.in/agriculture/agri_nutrientmgt_methodsoffertilizerappln

http://www.jains.com

http://www.odis.co.il

Suggested Reading:

-

James, L. G. (1988). Principles of Farm Irrigation System Design, John Willey & sons, Inc. New York.

-

Rajput, T.B.S. and Patel Neelam. (2002). Fertigation Theory and Practice, Water Technology Centre, IARI, New Delhi.