Site pages

Current course

Participants

General

MODULE 1. Analysis of Statically Determinate Beams

MODULE 2. Analysis of Statically Indeterminate Beams

MODULE 3. Columns and Struts

MODULE 4. Riveted and Welded Connections

MODULE 5. Stability Analysis of Gravity Dams

Keywords

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

LESSON 27. Welded Joints: Basic Concept

In this lesson we will discuss different kinds of welded joints. Their design will be discussed in the next lesson.

27.1 Different Types of Welds

Welds may be broadly grouped into four types,

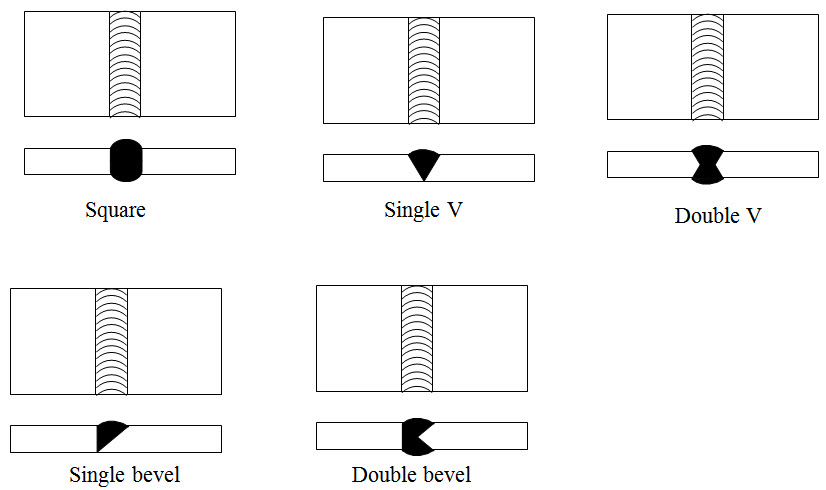

27.1.1 Groove welds

Groove welds are used to connect structural members that are aligned in the same plane and often used in butt joints. Various types of groove welds are depicted in Figure 27.1.

Fig. 27.1.

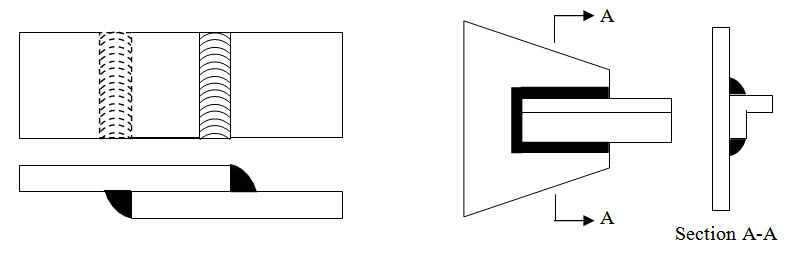

27.1.2 Fillet welds

Few examples of application of fillet welds are shown in Figure 27.2.

Fig. 27.2.

Fillets welds are mainly fail in shear.

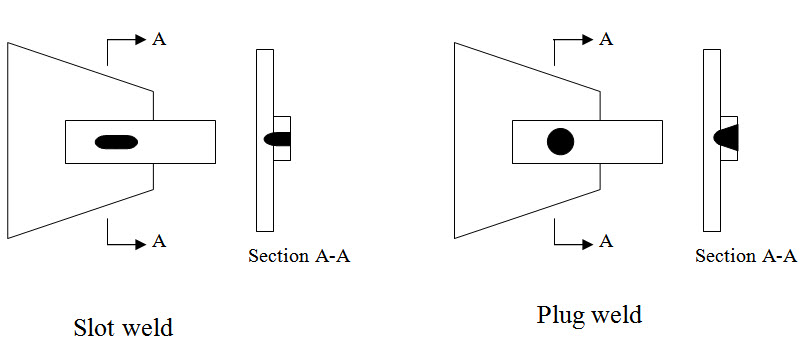

27.1.3 Slot and Plug welds

There may be situations where fillet welds cannot be used due to unavailability of sufficient length. In such cases slot and plug welds are used. They are also occasionally used to fill up holes in connections. Few examples are shown in

Figure 27.3.

Fig. 27.3.

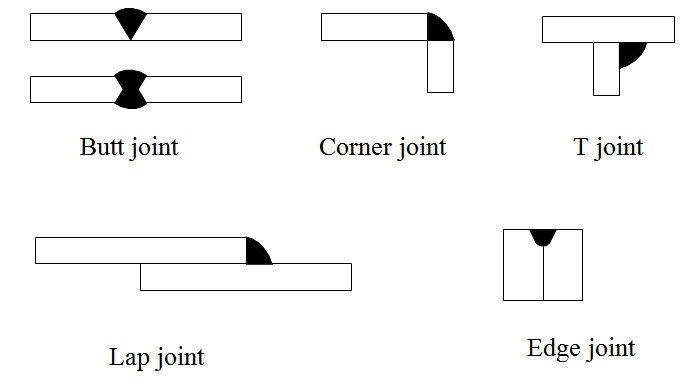

27.2 Types of Welded Joints

The types of welded joints depends on various factors such as size and shape of the member to be connected, area available for the joint, type of loading etc. The different types of welded joints commonly used are depicted in Figure 27.4.

Fig. 27.4.

27.3 Effective Area of Welds

The effective area of groove or fillet weld is determined as,

\[{{\rm{A}}_{{\rm{eff}}}}={t_e} \times {l_e}\]

where, te and le are the effective throat dimension and the effective length of the weld respectively.

Effective throat dimension (te) for different types of welds are given below.

27.3.1 Groove weld

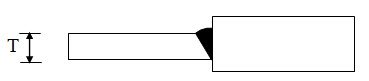

\[{t_e}={5 \over 8}T\] [T is the thickness of the thinner member (Figure 27.5)

Fig. 27.5.

27.3.2 Fillet weld

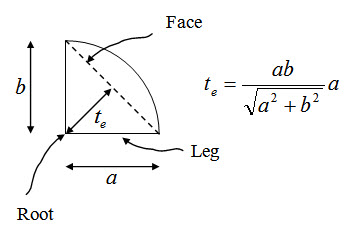

The effective throat dimension of fillet weld is the shortest distance from the root of the face of the weld.

Fig. 27.6.

For slot and plug weld, the effective area is taken as the nominal area of the hole in the plane of the faying surface.

Suggested Readings

Subramanian, N. (2008). Design of Steel Structures. Oxford University Press.

Duggal, S.K. (2010). Limit State Design of Steel Structures. First Edition, Tata McGraw - Hill Education.