Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

LESSON 22. PRINCIPLES OF FRUIT HARVESTING MACHINES

Some of the fruits are highly perishable products and required to be harvested in a very narrow range of time. These may be processed, graded, stored or consumed fresh, soon after harvesting. Because of these reasons, it is very important to mechanize the harvesting of fruits. High yielding and uniformly maturing varieties need to be harvested mechanically. Mechanical harvesting can result in an extremely high rate of product output in which case material handling methods are of major importance. Handling of fruits should be such that, there should be minimum damage to the product. In general, mechanically harvested fruits contain considerable quantities of trash, immature or damaged fruit, which has to be removed either during harvesting itself or separately and later on manually.

In India, very little efforts have been made to mechanize harvesting operation on fruit and vegetables. It is mainly due to availability of abundance of labour and lack of organized large-scale fruit or vegetable farming. However the nation’s cereal requirements are now being met through systematic approach and importance of fruit and vegetables production is in the process. Now the trend is emerging towards the organized fruit and vegetable farming. As this trend will continue, there is a need to develop simple mechanical devices for harvesting fruit and vegetable. In traditional method of harvesting tall tree fruits such as mangoes, palm, coconut etc many serious accidents happen every year. By developing simple mechanical harvesting devices may avoid such accidents or reduce it.

A lot of efforts have been made towards the fruit and vegetable harvesting, abroad. Harvest mechanization has reached a high level of success and acceptance for number of crops. Successful mechanization of these operations requires a systems approach and need the joint efforts of engineers, plant physiologists, food scientists and others. Mechanical harvesting often causes a reduction in harvested crop value per unit area mainly due to

Crop do not mature uniformly,

Fruit and vegetable damage,

Actual field losses, and

Reduction in quality.

Fruit Harvesting: There are varieties of fruits available, which need to be harvested at their maturity. Many fruits do not mature uniformly, which needs several pickings to obtain maximum yields. In general fruits can be categorized into three types, namely, tree fruits, vine fruits and bush fruits. Tree fruits are mangoes, apples, papayas; vine fruits watermelon, muskmelons etc and bush fruits are raspberries, blueberries, cranberries etc. Various principles and devices have been tried for harvesting fruits and are described below:

Tree fruit harvesting using shake and cater principle

This type of machine works on the principle of accelerating each fruit so that inertia force developed will be greater than bonding force between the fruit and the tree. The shaking machines based on this principle are already in use for fruits like walnut, almonds etc. Tractor mounted cable shakers, fixed stroke boom shakers and boom type impact knockers are basically used for nuts. Impact knockers are preferred for almonds, because they are large and rigid trees. An impact knocker makes impulses with the help of mechanical, hydraulic or pneumatic means. An electric wheel or crank on the tractor drives fixed stroke boom shakers clamped to the limb of tree. It may also be powered through self-propelled unit.

Fruit like apple, mangoes and pears can be harvested by shaking and catch method. The tree trunk or limb is shaken with a vibratory member and fruits are caught on canvas aprons. In some of the machines fruits may be dropped right on the ground. The methods for fruit removal from tree are limb shaking boom and inertia type, trunk shaking, and persuading air and vibration. Inertia type shakers are preferred over the stroke shakers. In an inertia shaker, the exciting force is derived from acceleration of a reciprocating mass or two opposite rotating eccentric weight. Both arrangements are so designed that it provides sinusoidal or nearly too sinusoidal force vibration. The shaker is generally mounted on the catching frame itself and therefore needs other vehicle. In the trunk shaker type machines, the fruit removal occurs simultaneously over the entire tree and the falling fruits are distributed over the entire catching space. It requires a considerable amount of power and is not suitable for very large trees.

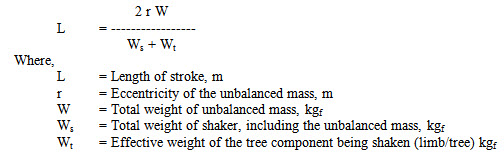

The clamp stroke length for inertia shaker having exciting frequency larger than the fundamental frequency of tree component, can be computed by using the following equation:

It has been observed that, usually the effective weight ‘Wt’ of tree component of trunk having a diameter of 12 to 28 cm varies from 365 to 450 kgf and for limbs of diameter 5 to 15 cm ranges from 10 to 30 kgf. Operating frequencies vary from 400 to 1200 cycles per minute for limb shaker and 800 to 2500 cycles per minute for trunk shakers. For delicious fruits, stroke length ranges from approximately 10 to 20 mm for trunk shakers and 38 to 51 mm for limb shakers. The catching units have low profile collection surfaces that extend under the tree, covering all or most of the area to the outer periphery of the tree. Some of the most commonly used catching arrangements are the inverted umbrellas wrap around type and the pained catching units. A good catching design minimizes the fruit damage.

Manual fruit harvesting device: There are two types of manual fruit harvesting devices. One unit works on the principle of individual cutting of fruit by sickle or blade and collecting it in a bag. In this unit, there is a telescopic boom, which can be fixed at required height through adjustable mechanism. Cutting units consists of two blades, one fixed and other movable. The movable blade is moved with the help of wire string. The individual fruit is cut and collected in the attached bag. This mechanism is very much suitable for fruits, which may get damaged if they fall freely on the ground like coconut, orange, mango, papaya and similar such fruits.

The other type of manual fruit harvester is based on the principle of shaking the branches or trunk of the tree. It consists of two tongs, adjustable to different heights by means of extension bars. A crank arrangement, to be operated manually and provided with flywheel to shake the tree at proper frequency, is connected to tongs and placed on the ground. The tongs are fixed with main branch of the tree and shaken to detach fruit. In order to save fruit from damaging, a net around tree can be stretched to collect falling fruits.

Harvesting of tree fruits with man positioners: Fresh fruits for marketing in the fruit markets are picked up by using a device called man position. In this device, a self-propelled machine is used which has an arrangement to position the worker’s platform at three-dimensional direction. Picking platforms and other types of man positioners may reduce harvesting cost. This type of machine can have multilevel picking platforms, which can move along continuously and worker can pick the fruits. The fruits can be put in bin or conveyors.

Citrus harvesting: Citrus fruit like orange, kinnow, malta and similar such fruits can be harvested by using inertia type limb shakers. It can also be harvested by using an oscillating air blast. In one arrangement, air at very high speed is discharged from 2 outlets, which is directed towards one side of tree as the machine moves down the row. This system is attractive because of its high potential capacity. Fruit removal percentage varies from 60 to 90%.

Grape harvesting: Development of grape harvesting machine is complicated due to number of reasons, like variety difference, raising methods, topography etc. Attempts have been made to harvest grapes with vertical stroke harvesters, which have one impacter per row. This is a self-propelled machine, which may have a stroke of 12 cm or more, with frequency of 250 to 500 rpm. In this machine, shaking is carried out by slopping the vines from the sides.

Can fruits, bush and strawberry harvesting: Machines that provided with vibrating devices could harvest bushy fruits such as blueberries, blackberries, and raspberries. One type of harvesting machine has radial, vertical vibrated fingers on free turning vertical cylinders. In other type of design, horizontal stroke peddles or panels of fingers vibrated vertically or horizontally. In such devices leaves are taken out with the help of air blast. It also removes other lighter materials from harvested fruit. It has been observed that blueberries and can fruits ripening takes several weeks and hence it makes necessary to have multiple harvesting. Selective mechanical harvesting is possible because mature fruits detach more easily than immature fruits. Strawberries are low growing, easily bruised and highly perishable and require multiple harvesting when picked manually by hand. Because of above problems, most of such harvesting machines have some stripping or combing type of mechanism. Leaves and other lighter materials are cleaned with air blast. In this type of harvesting machines some immature fruit also comes up which are removed by hand.