Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

LESSON 23. TYPES OF FRUIT HARVESTING MACHINES

Manual Fruit Harvester

It consists of one fixed blade and another moving blade actuated by a spring. There is a net basket attached to it to collect plucked mango fruits. The long handle facilitates reaching fruits from ground. During harvesting, the fruit pedicel is adjusted to rest on fixed blade and pressing the lever at the grip end of the handle actuates the moving blade. The overall length of the tool is about 3000 mm and the weight of the cutting head is 1.3 kg. The blades are made from carbon steel. The device is also used for harvesting oranges apple and sapota

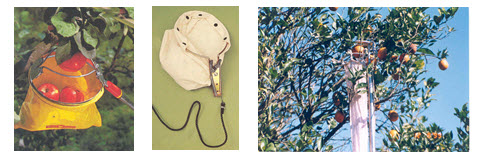

Hold on and twist type

It is a manual-harvesting tool with which individual fruit is first held between two jaws of the device and then twisted to shear off the stock. The jaws are made of 14 gauge mild steel sheet. These are held together by a tension spring on a pivot fitted on 10 mm mild steel rod. A handle can be fitted to the tool. One of the jaws has a lever bracket and rope arrangement for operating the jaw. Three mm thick rubber sheet padding is provided on inside of the jaws to avoid any skin damage while holding the fruits. After its detachment, fruit is released by pulling the cord in to a ring. A cloth conveyor or net is provided below the jaws for collection of harvested fruits at ground level without any damage. The tool is suitable for harvesting peach, pear and orange. Its field capacity is 250-300 fruits /man-h.

A manual-harvesting device has been also developed and commercialised for harvesting mango fruit with panicle. It consists of an oval shaped rings. The bottom ring is meant for fastening nylon net. A cutting mechanism is provided at the top of the ring and it consists of double bladed triangular plate together with toothed wheel. This toothed wheel is riveted at the center of the two fixed cutting blades. The wheel rotates freely about its central rivet and acts as a conveyor of a mango stock. For fixing a bamboo handle of desired length, a holder is provided to the harvester opposite to the cutting mechanism. A plastic divider rod bisecting the cutting mechanism is provided in the ring to guide the stalk of fruits either to the left or to the right side of the cutting blade. For harvesting mango, the harvester is raised and fruit is taken in the ring by pulling the harvester. The pedicels of the fruit are taken in between the toothed wheel and blade. On rotation of a toothed wheel, the pedicle is guided over the sharp edge of the blade where it is sheared. Field capacity of the device is 140 fruits/h. The devices are used for harvesting of fruits.

Manually Operated Sapota Harvester

The harvester is used for harvesting of small fruits like lemon, sapota etc. It consists of main body of PVC having cylindrical shape. The upper end of the body is closed while bottom end is open to which nylon net for collecting the fruits is tied. A stretched string closes the other end of the net. A gate is made on the body for entry of the fruits to be harvested. On the lower surface of the body a metal holder is fixed to hold the bamboo of required length. Two fingers cut in V-shape and with small sharp blades are provided at the closed end of the body of the harvester. The fingers help to select and hold the fruit to be harvested from the bunch. By pulling the harvester, fruit is detached from the bunch, which falls in the body and rolls into the net. To unload the harvested fruits in the net a stretched string at the closed end of the net is loosened.