Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

19 April - 25 April

26 April - 2 May

LESSON 1. HYDRAULIC BASICS

Introduction

Electrical motors can provide rotary motion, which if required can be converted into linear motion by devices such as screw jack or rack and pinions etc. For very short stroke, say upto 10 mm, a solenoid may be used to obtain linear motion directly.

Enclosed fluids (both liquids and gases) can also be used to produce rotary or linear motion or apply a force. Fluid based systems using liquids as transmission medium are called hydraulic systems, whereas gas based systems are called pneumatic systems.

A comparison of main features of electrical, hydraulic and pneumatic systems is given in Table 1.1.

Table 1.1 Comparison of Electrical, Hydraulic and Pneumatic Systems

|

|

ELECTRICAL |

HYDRAULIC |

PNEUMATIC |

|

ENERGY SOURCE |

Electrical power station |

Electric motor or Diesel engine |

|

|

ENERGY STORAGE |

Limited (batteries) |

Limited (accumulator) |

Good (reservoir) |

|

DISTRIBUTION SYSTEM |

Excellent with minimum losses |

Limited |

Good (plant wide) |

|

ENERGY COST |

Lowest |

Medium |

Highest |

|

ACTUATOR |

AC motors cheap, Good speed control in DC motors, Short linear motion with solenoids |

Low speed with good control |

Wide speed range, speed control difficult |

|

FORCE AVAILABLE |

Low |

High |

Medium |

|

HAZARDS |

Electric shock |

Oil leakage dangerous and unsightly |

Noise |

1.2 Hydraulics

When a force is applied on a liquid in an enclosed vessel, a uniform pressure is exerted on the liquid throughout the enclosed volume. Any leak in the vessel will decrease the pressure. Hydraulics is the science of transmitting force or motion or both through the medium of confined liquid. In hydraulic devices, power is transmitted from one location to another by applying a force on a confined liquid, to produce rotary or linear motion or to apply a force. To operate liquid-powered systems, it is required to have knowledge of the basic nature of liquids as the basic principles of hydraulics are based on certain characteristics of liquids

- Liquids have no shape of their own. However, they have definite volume.

- Liquids acquire the shape of the container they are put in.

- Liquids always seek a common level.

Therefore, oil in a hydraulic system will flow in any direction and through any passage, regardless of size or shape. Liquids are basically incompressible, which gives them the ability to transmit force. The pressure applied to a liquid in a sealed vessel is transmitted equally in all directions and to all areas of the system. Since force equals pressure times area, liquids can provide great increases in the force available to do work by getting larger area to system pressure.

1.3 Brief History

Humans recognized fluids as a source of power long ago. Water is available in nature and water flowing under pressure has two forms of energy – kinetic and potential energy. This natural source of energy has been harnessed by humankind since early ages for irrigation and to drive simple machines.

Joseph Bramah (1748 -1814), an inventor and locksmith of England, got a patent for his invention of the hydraulic press in 1795. William George Armstrong (1810 – 1900), a successful industrialist of England, developed hydraulic accumulator, a cast-iron cylinder fitted with a plunger supporting a very heavy weight. Both Bramah and Armstrong are considered fathers of hydraulic engineering.

In the early stages of industrial development, mechanical linkages had been used along with prime movers, like electric motors and engines, for handling loads. But, the mechanical efficiency of linkages is very low and these often fail under certain working conditions. With the advent of fluid power technology, several applications, where motion and/or force are primary requirements, started using hydraulic power.

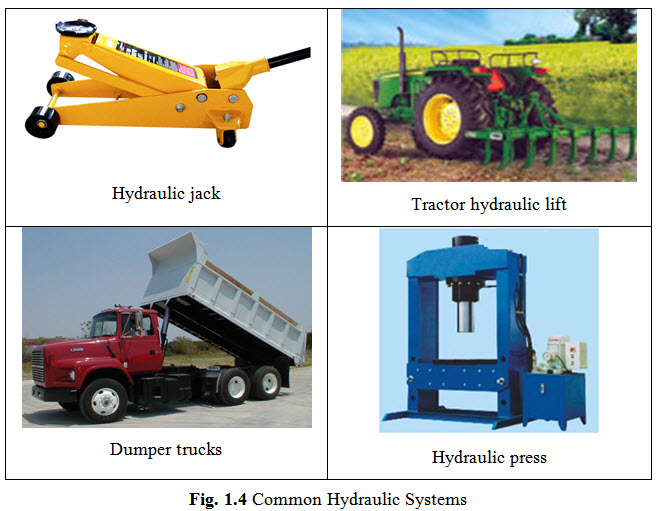

Common examples of applications of hydraulic systems which we come across now-a-days are shown in Fig. 1.4.

1.4 Advantages of Hydraulic Systems

The advantages of hydraulic systems over other methods of power transmission are:

Automation: Complete automation in many cases is possible with the use of hydraulics

Power to Weight Ratio: A high power to weight ratio is available in comparison with electrical and pneumatic systems.

Simpler design: In most cases, readily available components, such as cylinders and valves, can be used to build a hydraulic system.

Flexibility: Hydraulic components can be located with considerable flexibility. Pipes and hoses in place of mechanical elements reduce location problems.

Smoothness: Hydraulic systems are smooth and quiet in operation. Vibration is kept to a minimum.

Lubrication: Since oil is used as working medium, separate lubrication of various components is not required.

Bidirectional: Hydraulic systems or devices can be operated in forward (clockwise) or backward (anticlockwise) directions easily.

Control: Control of a wide range of speed and forces is easily possible.

Responsive: Since the medium used for power transmission in hydraulic systems is incompressible, they exhibit a quick response.

Transmission Efficiency: Hydraulic systems exhibit high efficiency due to minimum friction loss.

Overload protection: Automatic valves guard the system against a breakdown from overloading.

1.5 Disadvantages of Hydraulic Systems

The following disadvantages are associated with hydraulic systems:

Initial Cost: The initial cost of hydraulic systems is high.

Leakage: Oil leakage in hydraulic systems results in unsightly and slippery conditions.

Protection against Dirt / Water: Protection is required against dirt and water entering hydraulic system.

Maintenance: Frequent maintenance in terms of gaskets, seals and packagings etc. is required.

Hazardous: Oil leakage is a fire and environment hazard.

1.6 Hydraulic Systems Fundamentals, Operation and Control

The knowledge of the following is necessary for understanding the working of hydraulic systems, their operation and control:

Physical units for fluid power

Principles of fluid power

Fluids used in hydraulic systems

Hydraulic power packs

Hydraulic system components

Fittings and connectors

Basic hydraulic circuits

Design of hydraulic circuits

Maintenance and troubleshooting

In the next lecture, the physical units for fluid power and units of measurement will be discussed. Also the basic hydraulic system and its terminology will be introduced.