Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 11. Biogas technology

Energy Conversion routes – Biochemical conversion method – biogas – principle

Biomass is organic material made from plants and animals. Biomass contains stored energy from the sun. Plants absorb the sun's energy in a process called photosynthesis. The chemical energy in plants gets passed on to animals and people that eat them. Biomass is a renewable energy source because we can always grow more trees and crops, and waste will always exist. Some examples of biomass fuels are wood, crops, manure, and some garbage.

When burned, the chemical energy in biomass is released as heat. If you have a fireplace, the wood you burn in it is a biomass fuel. Wood waste or garbage can be burned to produce steam for making electricity, or to provide heat to industries and homes.

Burning biomass is not the only way to release its energy. Biomass can be converted to other usable forms of energy like methane gas or transportation fuels like ethanol and biodiesel. Methane gas is the main ingredient of natural gas. Smelly stuff, like rotting garbage, and agricultural and human waste, release methane gas - also called "landfill gas" or "biogas." Crops like corn and sugar cane can be fermented to produce the transportation fuel, ethanol. Biodiesel, another transportation fuel, can be produced from left-over food products like vegetable oils and animal fats.

Typical biomass supply is derived from:

-

Woody forest residue, fuelwood, mill residues, short rotation crops,

-

Non-woody agricultural crops, crop residue, processing residues; and

-

Animal waste such as manure from feed lots and municipal sewage and waste.

Biomass energy – Direct and indirect uses

Biomass energy can be used directly or indirectly. Firewood is a common example of direct use by combustion. But biomass energy can be transformed into other forms of fuel. Ethanol from agricultural crops such as sugar cane and methane from manure and sewage are examples of indirect use fuel. Ethanol from agricultural crops such as sugar cane and methane from manure and sewage are examples of indirect use.

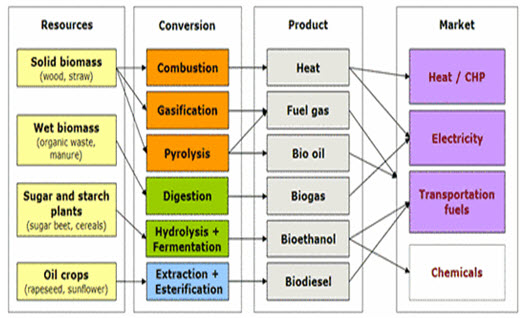

Biomass energy – conversion

Biomass energy in the forms of gas can occur spontaneously, as marshgas, or landfill gas for example, but alcohols do not. Agricultural wastes or manures undergo certain processes first.

The two main processes are thermal and biological

Thermal and biological biomass energy conversion

Thermal conversion can happen in three ways

-

Combustion, (including co-firing - mixed coal/biomass combustion)

-

Woodchips

-

Pyrolysis and,

-

Gasification

Combustion of course means that biomass is burned, similar to coal and oil, to make electricity. When mixing biomass with coal, this co-firing process is very efficient. Solid municipal waste is also burned to generate electricity.

Pyrolysis is a chemical process of decomposition of biomass materials. It is a heating process without the involvement of oxygen. The recycling of used vehicle tyres uses pyrolysis.

Gasification involves processes that turn parts of solid biomass materials into gas. Pyrolysis can do this for example.

Biological conversion can happen through

Digestion and fermentation of biodegradable wastes occurs in large digester power plants where bacteria convert waste into gas. The produced gas drives turbines that generate electricity from these wastes. The solids that are left behind may be used as fertilizer, depending on the biomass materials used.

Biofuels that can be made from biomass are

Biogas

Bioethanol

Biobutanol and

Biodiesel

Biogas

Biogas can be captured from marshes, from landfill or wastes such as sewage, and burned to produce electricity. It can also be generated intentionally through anaerobic composting. When refined it can be used to power vehicles directly.

Biogas, a mixture containing 55-65 percent methane, 30-40 percent carbon dioxide and the rest being the impurities (H2, H2S, and some N2), can be produced from the decomposition of animal, plant and human waste. It is a clean but slow burning gas and usually has a colorific value-between 5000 to 5500 kcal/kg. It can be used directly in cooking, reducing the demand for firewood. Moreover, the material from which the biogas is produced retains its value as a fertilizer and can be returned to the soil. Biogas has been popular on the name, "Gobar Gas" mainly because cow dung has been the material for its production, hitherto. It is not only the excreta of the cattle, but also the piggery Waste as well as poultry droppings are very effectively used for biogas generation. A few other materials through which biogas can be generated are algae, crop residues (agro-wastes), garbage kitchen wastes, paper wastes,. sea wood, human waste, waste from sugarcane refinery, water hyacinth etc., apart from the abovementioned animal wastes. Any cellulosic organic material of animal or plant origin, which is easily biodegradable, is a potential raw material suitable for biogas production.

Biogas is produced by digestion, pyrolysis, or hydrogasification. "Digestion biological process that occurs in the absence of, oxygen and in the presence of anaerobic organisms at ambient pressures and temperatures of 35-70°C. The container in which this digestion takes place is know as the digester

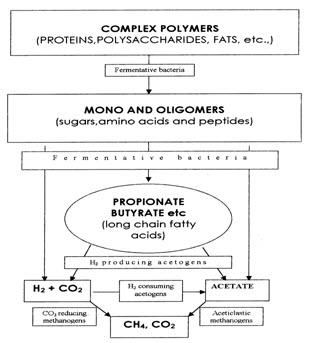

Stages of anaerobic digestion in methane production

Formerly, methane fermentation was hypothetically designed as a two-step process including an acid forming stage followed by a methane forming stage. However, with the exception of methanol, acetate and formate, methanogenic bacteria cannot metabolize alcohols and organic acids.

The current scheme represents a three-stage process in which three groups of bacteria are involved.

a. Hydrolytic and acidogenic bacteria

b. Acetogenic bacteria

c. Methanogenic bacteria

Fig : Microbial groups involved in the conversion of biomass to methane

Manure Collection

Livestock facilities use manure management systems to collect and store manure because of sanitary, environmental, and farm operational considerations. Manure is collected and stored as liquids, slurries, semi-solids, or solids.

Raw Manure. Manure is excreted with a solids content of 8 to 25 percent, depending upon animal type. It can be diluted by various process waters or thickened by air drying or by adding bedding materials.

Liquid Manure. Manure handled as a liquid has been diluted to a solids content of less than 5 percent. This manure is typically “flushed” from where it is excreted, using fresh or recycled water. The manure and flush water can be pumped to treatment and storage tanks, ponds, lagoons, or other suitable structures before land application. Liquid manure systems may be adapted for biogas production and energy recovery in “warm” climates. In colder climates, biogas recovery can be used, but is usually limited to gas flaring for odor control.

Slurry Manure. Manure handled as slurry has been diluted to a solids content of about 5 to 10 percent. Slurry manure is usually collected by a mechanical “scraper” system. This manure can be pumped, and is often treated or stored in tanks, ponds, or lagoons prior to land application. Some amount of water is generally mixed with the manure to create a slurry. For example, spilled drinking water mixes with pig manure to create a slurry. Manure managed in this manner may be used for biogas recovery and energy production, depending on climate and dilution factors.

Semi-Solid Manure. Manure handled as a semi-solid has a solids content of 10 to 20 percent. This manure is typically scraped. Water is not added to the manure, and the manure is typically stored until it is spread on local fields. Fresh scraped manure (less than one week old) can be used for biogas and energy production in all climates, because it can be heated to promote bacterial growth.

Solid Manure. Manure with a solids content of greater than 20 percent is handled as a solid by a scoop loader. Aged solid manure or manure that is left “unmanaged” (i.e., is left in the pasture where it is deposited by the animals) or allowed to dry is not suitable for biogas recovery.

Effluent Storage

The products of the anaerobic digestion of manure in digesters are biogas and effluent. The effluent is a stabilized organic solution that has value as a fertilizer and other potential uses. Waste storage facilities are required to store treated effluent because the nutrients in the effluent cannot be applied to land and crops year round.

The size of the storage facility and storage period must be adequate to meet farm requirements during the non-growing season. Facilities with longer storage periods allow flexibility in managing the waste to accommodate weather changes, equipment avail- ability and breakdown, and overall operation management.

Gas Handling

A gas handling system removes biogas from the digester and transports it to the end-use, such as an engine or flange. Gas handling includes: piping; gas pump or blower; gas meter; pressure regulator; and condensate drain(s).

Biogas produced in the digester is trapped under an airtight cover placed over the digester. The biogas is removed by pulling a slight vacuum on the collection pipe (e.g., by connecting a gas pump/blower to the end of the pipe), which draws the collected gas from under the cover. A gas meter is used to monitor the gas flow rate. Sometimes a gas scrubber is needed to clean or “scrub” the biogas of corrosive compounds contained in the biogas (e.g., hydrogen sulfide). Warm biogas cools as it travels through the piping and water vapor in the gas condenses. A condensate drain(s) removes the condensate produced.

Gas Use

Recovered biogas can be utilized in a variety of ways. The recovered gas is 60 - 80 percent methane, with a heating value of approximately 600 - 800 Btu/ft3. Gas of this quality can be used to generate electricity; it may be used as fuel for a boiler, space heater, or refrigeration equipment; or it may be directly combusted as a cooking and lighting fuel.

Electricity can be generated for on-farm use or for sale to the local electric power grid. The most common technology for generating electricity is an internal combustion engine with a generator. The predicted gas flow rate and the operating plan are used to size the electricity generation equipment.

Engine-generator sets are available in many sizes. Some brands have a long history of reliable operation when fueled by biogas. Electricity generated in this manner can replace energy purchased from the local utility, or can be sold directly to the local electricity supply system. In addition, waste heat from these engines can provide heating or hot water for farm use.

Biogas can also be used directly on-site as a fuel for facility operations. Equipment that normally uses propane or natural gas can be modified to use bio- gas. Such equipment includes boilers, heaters, and chillers.

-

Boilers and Space Heaters. Boilers and space heaters fired with biogas produce heat for use in the facility operations. Although this may not be the most efficient use of the gas, in some situations it may be a farm’s best option.

-

Chilling/Refrigeration. Dairy farms use considerable amounts of energy for refrigeration. Approximately 15 to 30 percent of a dairy’s electricity load is used to cool milk. Gas-fired chillers are commercially available and can be used for this purpose. For some dairies, this may be the most cost effective option for biogas utilization.

Other energy use options may exist. For example, a nearby greenhouse could be heated with the biogas, and carbon dioxide from the heater exhaust could be used to enhance plant growth. These options need to be evaluated on a case-by-case basis.

Benefits of Biogas Technology

Most confined livestock operations handle manure as liquids, slurries, semi-solids, or solids that are stored in lagoons, concrete basins, tanks, and other containment structures. These structures are typically designed to comply with local and state environmental regulations and are a necessary cost of production.

Biogas technology can be a cost-effective, environment and neighborhood friendly addition to existing manure management strategies. Biogas technologies anaerobically digest manure, resulting in biogas and a liquefied, low-odor effluent. By managing the anaerobic digestion of manure, biogas technologies significantly reduce Biochemical Oxygen Demand (BOD), and pathogen levels; remove most noxious odors; and convert most of the organic nitrogen to plant available inorganic nitrogen.

The principal reasons a farmer or producer would consider installing biogas systems are:

-

On-Site Farm Energy. By recovering biogas and producing on-farm energy, livestock producers can reduce monthly energy purchases from electric and gas suppliers.

-

Reduced Odors. Biogas systems reduce offensive odors from overloaded or improperly man- aged manure storage facilities. These odors impair air quality and may be a nuisance to nearby communities. Biogas systems reduce these offensive odors because the volatile organic acids, the odor causing compounds, are consumed by biogas producing bacteria.

-

High Quality Fertilizer. In the process of an- aerobic digestion, the organic nitrogen in the manure is largely converted to ammonium. Ammonium is the primary constituent of commercial fertilizer, which is readily available and utilized by plants.

-

Reduced Surface and Groundwater Contamination. Digester effluent is a more uniform and predictable product than untreated manure. The higher ammonium content allows better crop utilization and the physical properties al- low easier land application. Properly applied, digester effluent reduces the likelihood of surface or groundwater pollution.

-

Pathogen Reduction. Heated digesters reduce pathogen populations dramatically in a few days. Lagoon digesters isolate pathogens and allow pathogen kill and die-off prior to entering storage for land application.

Biogas recovery can improve profitability while improving environmental quality. Maximizing farm resources in such a manner may prove essential to remain competitive and environmentally sustainable in today’s livestock industry. In addition, more widespread use of biogas technology will create jobs related to the design, operation, and manufacture of energy recovery systems and lead to the advancement of U.S. agribusiness.