Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 22. Recent trends in solar drying-solar tunnel drier

In India, Only 2-3 % of agricultural produce is being processed. Reduction of post harvest losses is inevitable. According to FAO reports, Crop loss accounts about 5-10 % (Paddy alone during Harvesting and Marketing : 30-50%),Fruits and vegetables is about 10 to 30 %, Pulses 8-10 %, Food and agricultural Commoditiesloss is about 20-50%.Drying process alone can reduce post harvest loss of 2-3 %. Uniform drying and quality of product is essential for better marketability. Reduction of fossil fuel usage and dependence of conventional power for drying process. Utilization of renewable energy is essential to reduce GHG emissions. Effective drying mechanism is needed for the hour for enhancing value of agro-produce.Our country is blessed with abundant solar energy available for more than 300 days in a year.

System specification

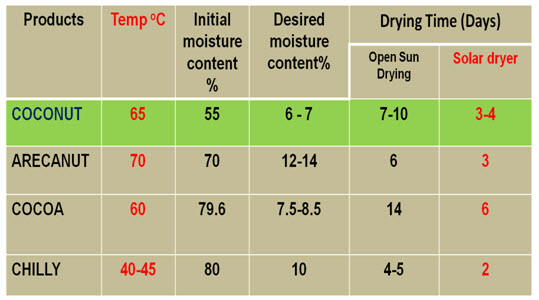

Solar tunnel drier utilizes solar thermal energy for drying applications. Its working principle is based on green house gas effect. Studies illustrates that a solar tunnel drier of 0.5 to 1.5 tonnes of productcapacity occupy a size of 18.0 m x 3.75 m x 2.0 m. The system possesses semi-cylindrical tunnel structure with hoops and laterals. Solar collector material is of UV stabilized polyethylene with 200 µm thickness. Absorber surface is of cement concrete flooring with special black coating and is provided with equi-spaced chimney for natural ventilation. Temperature boosted upto 20-25oC than ambient in this drier. Drying time is reduced up to 50% and labour requirement is also reduced to 40 % than conventional drying.

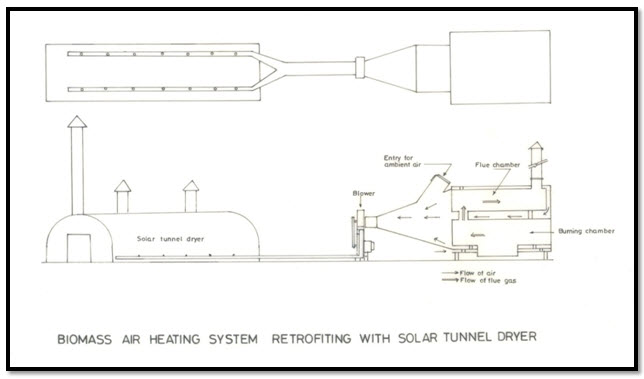

Following figures gives clear understanding about solar tunnel drier.

Drying Parameters of various agro products

Control measures

Required instruments need to be provided to control the conditions and drying parameters of various agro-products at different temperature at different seasons and to match the integration of Solar d ryer and Biomass hot air generation systems. Controlling and monitoring systems have to be paneled to drying the products by solar energy mode during the day hours and by biomass hot air generation system during the night hours. Each and every agro-product needs certain quality which is induced by different temperature and relative humidity. Regulating the drying parameters can be possible thro’ instrumentation. As the natural exhaust system differs with respect to time, it is important to have controlled condition to regulate the drying parameters as well.