Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 23. Solar Driers

Conventional method of drying is to spread the material in a thin layer on ground and let it exposed to the sun. Such a method has various disadvantages like,

-

Accumulation of dust and harms due to insects

-

Wastage of material due to birds

-

Non uniform drying due to varying intensity of sun

-

Larger area required for drying

All these difficulties are removed by using solar drier. There are two types of solar driers.

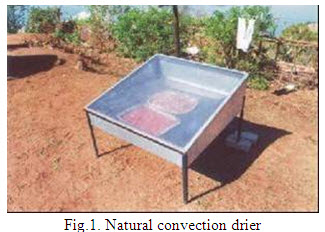

Natural convection solar drier

Natural air-drying is an in bin drying system with the following typical characteristics:

-

Drying process is slow, generally requiring 4 to 8 weeks.

-

Initial moisture content is normally limited to 22 to 24%.

-

Drying results from forcing unheated air through grain at airflow rates of 1 to 2 cfm/bu.

-

Drying and storage occur in the same bin, minimizing grain handling.

-

Bin is equipped with a full-perforated floor, one or more high capacity fans, a grain distributor and stairs

-

Cleaning equipment is used to remove broken kernels and fines.

Fig.2. Natural convection cabinet drier

Description of Cabinet drier

It can be of fixed type and also of portable type. Generally it has an area of about 3 x 5 m2 glass sheet fixed at the top at an angle of about 0 to 300. Holes are provided at the bottom and at the topsides for airflow by natural convection. Wire meshed black tray is provided to the material to be dried.

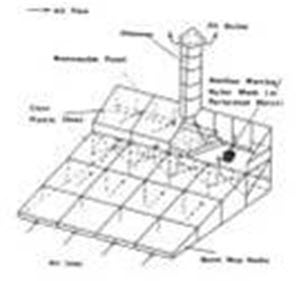

Forced convection solar dryer (Hot air system):

In these, the collectors are provided with duct. Generally, a duct of 2.5 cm depth is provided. It is made out of two plates welded together lengthwise. Cold air is blown through a blower into the collectors, which gets heated during the passage through it. The hot air thus available is then used for drying the products kept on the shelves of driers. This hot air takes away the moisture of the products and is let out through a properly located outlet.

-

Absorber with ducting

-

Blower with motor and

-

Drying bin

Description

This drier has three main components viz., flat plate collector, blower and drying bin. The area of the collector is 8m2. It is divided into 4 bays each having 2m x 1 m absorber area. The absorber is made out of 20 g. corrugated G.I. sheet and is painted with dull black colour. Another plain G.I. sheet placed 5 cm below the absorber plate creates air space for heating. This sheet is insulated at the bottom with glass wool and is supported at the bottom with another plain G.I. sheet. The absorber is covered at the top with two layers of 3 mm thick plain glass. The unit is supported on all sides with wooden scantling and is placed at 110 to the horizontal facing south. Baffle plates are provided in the air space. The air space is open at the bottom to suck atmospheric air and at the top it is connected to a duct leading to suction side of the blower. The blower is of 80 m3 / min, capacity run by 3HP electric motor. The delivery side of the blower is connected to the plenum chamber of a circular grain holding bin.

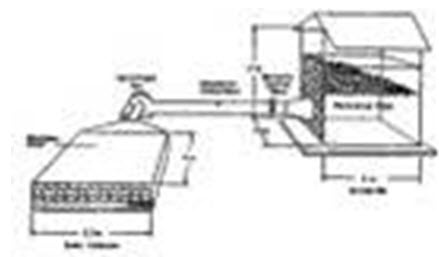

Fig.3. Forced convection drier

Forced Convection Solar Drier for Drying of Grains

For drying high moisture paddy the solar drier can be used. The different components of the drier are air heater, air ducts and blower and grain drying chamber. The flat plate collector used for heating the air has an efficiency of 60% and rise in ambient air temperature is 13oC. Freshly harvested paddy can be dried and it may take about 7-8 hours to bring the moisture content from 30% to 16% (d.b.). After drying the grains, the milling quality can be tested. The use of solar air heater for drying of grains indicates that 10-15oC rise in the temperature of the air is enough to reduce the relative humidity of the air to 60% or less which is quite useful for drying of cereal grains.

To the level consists of safe moisture content for storage 500 kg of paddy could be dried from 30 to 40 % moisture content in a period of 6 hours on bright sunny day by using air flow rate of 4 m3/min with temperature rise 8-10oC.

Solar drier consists of air heater, blower drying chamber, air distribution system and thermal storage system. The heated air is blown to drying chamber by blowers of the centrifugal type to handle large quantity of air. Batch type or continuous flow type drying chamber artificially creates the necessary radiation to reduce moisture. Hot air from the collector is sucked by a blower through the inlet pipe and is being forced into the drying chamber. An auxiliary heating system to supplement heat requirement may be arranged. This type of auxiliary systems and thermal storage systems for collecting extra energy during daytime, take care of the night operations.

The heat required Q in kcal/hr

Q = V x ρ x Cp x ΔT -------------- (1)

Where V = air flow rate, m3/hr

ρ = density of air, kg/ m3

Cp = the specific heat of air, and

ΔT = temperature rise.

Moisture content assessed per tonne of paddy (m) for drying pre-boiled paddy, yield the volume of air to be handled V from

m x latent heat = V x ρ x Cp x ΔT x efficiency ------------- (2)

The volume of rock pile required V’ for thermal storage of heat energy Q is

Q

V’ = --------------- --------------- (3)

ρ’ Cp’ ΔT’

Where ρ’ = density of rock

Cp’ = specific heat of rock

ΔT’ = temperature increase in rock.