Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 27. Wind energy conversion principles

The power in the wind

The wind systems that exist over the earth’s surface are a result of variations in air pressure.These are in turn due to the variations in solar heating. Warm air rises and cooler air rushesin to take its place. Wind is merely the movement of air from one place to another. There areglobal wind patterns related to large scale solar heating of different regions of the earth’ssurface and seasonal variations in solar incidence. There are also localised wind patternsdue the effects of temperature differences between land and seas, or mountains and valleys.Wind speed generally increases with height above ground. This is because the roughness ofground features such as vegetation and houses cause the wind to be slowed.Windspeed data can be obtained from wind maps or from the meteorology office.Unfortunately the general availability and reliability of windspeed data is extremely poor inmany regions of the world. However, significant areas of the world have mean annualwindspeeds of above 4-5 m/s (metres per second) which makes small-scale wind poweredelectricity generation an attractive option. It is important to obtain accurate windspeed datafor the site in mind before any decision can be made as to its suitability. Methods forassessing the mean windspeed are found in the relevant texts (see the ‘References andresources’ section at the end of this fact sheet).

The power in the wind is proportional to:

-

Area of windmill being swept by the wind

-

Cube of the wind speed

-

Air density - which varies with altitude

The formula used for calculating the power in the wind is shown below:

Power = density of air x swept area x velocity cubed

P = ½.ρ.A.V3

where, P is power in watts (W)

ρ is the air density in kilograms per cubic metre (kg/m3)

A is the swept rotor area in square metres (m2)

Wind for electricity generation Practical Action

V is the windspeed in metres per second (m/s)

The fact that the power is proportional to the cube of the windspeed is very significant. Thiscan be demonstrated by pointing out that if the wind speed doubles then the power in thewind increases by a factor of eight. It is therefore worthwhile finding a site which has arelatively high mean windspeed.

Wind into watts

Although the power equation above gives us the power in the wind, the actual power that wecan extract from the wind is significantly less than this figure suggests. The actual power willdepend on several factors, such as the type of machine and rotor used, the sophistication ofblade design, friction losses, and the losses in the pump or other equipment connected to thewind machine. There are also physical limits to the amount of power that can be extracted realistically from the wind. It can been shown theoretically that any windmill can only possiblyextract a maximum of 59.3% of the power from the wind (this is known as the Betz limit). Inreality, this figure is usually around 45% (maximum) for a large electricity producing turbineand around 30% to 40% for a windpump, (see the section on coefficient of performancebelow). So, modifying the formula for ‘Power in the wind’ we can say that the power which isproduced by the wind machine can be given by:

PM = ½.Cp.ρ.A.V3

where,

PM is power (in watts) available from the machine

Cp is the coefficient of performance of the wind machine

It is also worth bearing in mind that a wind machine will only operate at its maximumefficiency for a fraction of the time it is running, due to variations in wind speed. A roughestimate of the output from a wind machine can be obtained using the following equation;

PA = 0.2 A V3

where,

PA is the average power output in watts over the year

V is the mean annual windspeed in m/s

Principles of wind energy conversion

There are two primary physical principles by which energy can be extracted from the wind;these are through the creation of either lift or drag force (or through a combination of the two).The difference between drag and lift is illustrated by the difference between using a spinnakersail, which fills like a parachute and pulls a sailing boat with the wind, and a Bermuda rig, thefamiliar triangular sail which deflects with wind and allows a sailing boat to travel across thewind or slightly into the wind.Drag forces provide the most obvious means of propulsion, these being the forces felt by aperson (or object) exposed to the wind. Lift forces are the most efficient means of propulsionbut being more subtle than drag forces are not so well understood.The basic features that characterise lift and drag are:

-

Drag is in the direction of air flow

-

Lift is perpendicular to the direction of air flow

-

Generation of lift always causes a certain amount of drag to be developed

-

With a good aerofoil, the lift produced can be more than thirty times greaterthan the drag

-

Lift devices are generally more efficient than drag devices

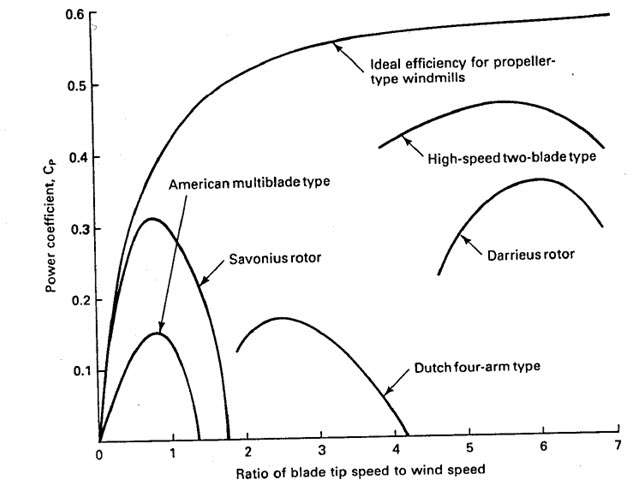

FIG. Performance of wind mill system.

Types and characteristics of rotors

There are two main families of windmachines: vertical axis machines and horizontal axisWind for electricity generation Practical Actionmachines. These can in turn use either lift or drag forces to harness the wind. The horizontalaxis lift device is the type most commonly used. In fact other than a few experimentalmachines virtually all windmills come under this category.There are several technical parameters that are used to characterise windmill rotors. The tipspeedratio is defined as the ratio of the speed of the extremities of a windmill rotor to thespeed of the free wind. Drag devices always have tip-speed ratios less than one and henceturn slowly, whereas lift devices can have high tip-speed ratios (up to 13:1) and hence turnquickly relative to the wind.The proportion of the power in the wind that the rotor can extract is termed the coefficient ofperformance (or power coefficient or efficiency; symbol Cp) and its variation as a function oftip-speed ratio is commonly used to characterise different types of rotor. As mentioned earlierthere is an upper limit of Cp = 59.3%, although in practice real wind rotors have maximum Cvalues in the range of 25%-45%.Solidity is usually defined as the percentage of the area of the rotor, which contains materialrather than air. Low-solidity machines run at higher speed and tend to be used for electricitygeneration. High-solidity machines carry a lot of material and have coarse blade angles. Theygenerate much higher starting torque (torque is the twisting or rotary force produced by therotor than low-solidity machines but are inherently less efficient than low-solidity machines.The windpump is generally of this type. High solidity machines will have a low tip-speed ratioand vice versa.

There are various important wind speeds to consider:

-

Start-up wind speed - the wind speed that will turn an unloaded rotor

-

Cut-in wind speed – the wind speed at which the rotor can be loaded

-

Rated wind speed – the windspeed at which the machine is designed to run(this is at optimum tip-speed ratio)

-

Furling wind speed – the windspeed at which the machine will be turned outof the wind to prevent damage

-

Maximum design wind speed – the windspeed above which damage could occur to the machine

Anatomy and characteristics of the wind generator

A typical small wind generator has rotor that is directly coupled to the generator, whichproduces electricity either at 120/240 volt alternating current for direct domestic use or at12/24 volt direct current for battery charging. Larger machines generate 3 phase electricity.There is often a tail vane which keeps the rotor orientated into the wind. Some windmachineshave a tail vane, which is designed for automatic furling (turning the machine out ofthe wind) at high wind speeds to prevent damage. Larger machines have pitch controlledblades (the angle at which the blades meet the wind is controlled) which achieve the samefunction. The tower is of low solidity to prevent wind interference and is often guyed to givesupport to the tower.

Grid connected or battery charging

Depending on the circumstances, the distribution of electricity from a wind machine can be carried out in one of various ways. Commonly, larger machines are connected to a grid distribution network. This can be the main national network, in which case electricity can be sold to the electricity utility (providing an agreement can be made between the producer and the grid) when an excess is produced and purchased when the wind is low. Using the national grid helps provide flexibility to the system and does away with the need for a back-up system when windspeeds are low.

Micro-grids distribute electricity to smaller areas, typically a village or town. When wind is used for supplying electricity to such a grid, a diesel generator set is often used as a backup for the periods when windspeeds are low. Alternatively, electricity storage can be used but this is an expensive option. Hybrid systems use a combination of two or more energy sources to provide electricity in all weather conditions. The capital cost for such a system is high but subsequent running costs will be low compared with a pure diesel system. In areas where households are widely dispersed or where grid costs are prohibitively expensive, battery charging is an option. For people in rural areas a few tens of watts of power are sufficient for providing lighting and a source of power for a radio or television. Batteries can be returned to the charging station occasionally for recharging. This reduces the inconvenience of an intermittent supply due to fluctuating windspeeds. 12 and 24 volt direct current wind generators are commercially available which are suitable for battery charging applications. Smaller turbines (50 -150 watt) are available for individual household connection.

Environmental concerns

Wind power is a clean renewable energy source. There are, however some environmental considerations to keep in mind when planning a wind power scheme. They include the following:

-

Electromagnetic interference - some television frequency bands are susceptible to interference from wind generators.

-

Noise - wind rotors, gearboxes and generators create acoustic noise when functioning; this needs to be considered when siting a machine.

-

Visual impact - modern wind machines are large objects and have a significant visual impact on their surroundings. Some argue that it is a positive visual impact, others to the contrary.