Site pages

Current course

Participants

General

Module 1. History and types of greenhouse

Module 2.Function and features of greenhouse

Module 3.Scope and development of greenhouse techn...

Module 4.Location, planning and various components...

Module 5.Design criteria and calculations

Module 6. Construction materials and methods of co...

Module 7. Covering material and characteristics

Module 8. Solar heat transfer

Module 9. Solar fraction for greenhouse

Module 10. Steady state analysis of greenhouse

Module No. 11 Greenhouse Heating, Cooling, Sheddin...

Module 12. Carbon dioxide generation and monitorin...

Module 13. Instrumentation and & computerized ...

Module 14. Watering, fertilization, root substrate...

Module 15. Containers and benches

Module 16. Plant nutrition, Alternative cropping s...

Module 17. Plant tissue culture

Module 18. Chemical growth regulation

Module 19. Disease control, integrated pest manage...

Module 20: Post Production Quality and Handling

Module 21: Cost analysis of greenhouse Production

Module 22. Application of greenhouse & its rep...

Lesson 29 Post Production Handling of Greenhouse Production

29.1 INTRODUCTION

Postharvest losses of fresh horticultural products usually exceed 25% of the total production and are caused by inappropriate control of the physical, physiological and microbiological conditions during storage and commercialization (Lioutas, 1998). The weight loss after harvest of fresh horticultural products is caused, mainly, by water loss through evaporation, which depends on the temperature and humidity of the surrounding environment and on the temperature of the product. The respiratory processes also contribute to the weight loss, but to a lesser extent, and are quite dependent on the temperature, increasing with it. Vegetable water loss causes a quality decrease in the form of product wilt, discoloration and loss of firmness. This water loss in some fruit vegetables, such as tomato, originates in the peduncles mainly, because the skin is practically impermeable, being possible to compare a tomato fruit to a container filled with water, because the water content may be as high as 95% (Scheer, 1994). Other vegetables such as cucumber, whose skin is much more permeable, are more sensitive to dehydration. Therefore, cucumbers are usually packed inside a plastic film to limit the postharvest water losses, as it is also common with leafy vegetables.

Whether you grow fresh product (fruits, vegetables or flowers) for the local farmers’ market and retailers or have a large operation that sells truckloads to the national wholesale market, you need to move your product from the field to your consumers in a manner that ensures a high quality product. For this it need proper post-harvest management.

29.2 POSTHARVEST HANDLING

29.2.1 Postharvest Handling of Fruits and Vegetables

The ideal management of vegetables starts with proper handling at harvest, an operation that should be done preferably in the morning, when the ambient temperature is lower. The harvested product must be protected from the sun, and whenever possible, to proceed immediately to their pre-cooling (fast cooling before processing) if such facilities are available. The most popular pre-cooling procedure is by forced air, which circulates air at low temperature (Tompson, 2003). Many vegetables are sensitive to cooling (chilling), that is they get damaged if exposed to low temperature (but above the freezing point) for a certain minimum period of time. Depending on their origin, tropical and subtropical fruits have their threshold for chilling at 10–15°C, whereas the threshold is lower for fruits that originate in temperate areas.

At 7°C chilling damage occurs in cucumber, aubergine, pepper, melon or ripened tomatoes, whereas for green tomatoes damage occurs at higher temperatures (Wang, 2003). Chilling damage can be very relevant if the low temperatures last a long time. If the duration of low temperatures is short, normal metabolic capacity in these plants is limited or cancelled, affecting their shelf life, although the damage is only evident when the product goes back to normal temperatures.

In general, tomatoes can be conserved well with a RH of 90%, but the optimal thermal regime varies depending on the ripening stage, the recommendation being for less than 15°C for green and early pink- colour stage tomatoes, and less than 10°C for late pink-colour stage and ripened fruits (Chaux and Foury, 1994a, b). The storage temperature allows for regulating the ripening speed; for instance, for pink-colour stage tomatoes, a temperature of 10°C allows them to ripen in 10–20 days, whereas at 20°C ripening is shortened to 8–10 days (Chaux and Foury, 1994b).

The optimal storage temperature of greenhouse cucumbers is from 12 to 13°C, because lower temperatures cause the fruits to wilt and higher temperatures accelerate their respiration and dehydration (Chaux and Foury, 1994b). Covering them in a plastic film extends their shelf life.

The optimal storage temperature of leafy vegetables is lower than for fruit vegetables. In general, while temperatures of 0–2°C, with RH of 90–98%, are optimal for some (artichokes, asparagus, broccoli, cabbage, cauliflower, Chinese cabbage, endives, lettuce, carrots and cantaloupe melons), the fruit vegetables are better conserved at 7–10°C, with RH of 85–95% (Tompson and Kader,2003). The usual greenhouse vegetables are all very sensitive to freezing (Wang, 2003). In fresh products, postharvest treatments with high temperatures can be of interest to control pests and insects and fungal diseases, before their storage or long- distance shipping. Washing the peppers with water at temperatures between 50 and 65°C, while simultaneously brushing them, has proved to be efficient for the control of postharvest diseases; the same is true for the treatment of tomatoes with hot water at 50°C for 2 min (Lurie and Klein, 2003).

A proper environmental humidity has a notable influence on maintaining the post- harvest quality of fruits and vegetables, especially during cold storage. An inappropriate humidity can increase the incidence of fungal diseases, alter the organoleptic characteristics and induce the cracking or cork-like texture of the fruits and vegetables (Scharz, 1994).

Storage in a controlled atmosphere involves the modification of the normal composition of the air (78% N2, 21% O2 and0.03% CO2), in order to have less than 8% of O2 and more than 1% of CO2, while keeping low temperature and adequate humidity according to the product being stored, which decreases the respiration rate of the product and the production of ethylene (Kader, 2003).

An optimum atmospheric composition delays: (i) the loss of chlorophyll (green colour); (ii) the biosynthesis of carotenoids (yellow and orange colours) and anthocyanins (red and blue colours); and (iii) the biosynthesis and oxidation of phenolic compounds (brown colour) (Kader, 2003). Low levels of O2 and/or high concentrations of CO2 in the air affect the flavour, decreasing the loss of acidity, the conversion of starch into sugar, the inter-conversions of sugars and the biosynthesis of volatiles that affect the flavour and aromas, resulting in an improvement of the nutritional flavour, as the ascorbic acid and other vitamins remain in the fruits (Kader, 2003).

In addition to a delay in senescence, storage under a controlled atmosphere decreases the sensitivity to ethylene (if the O2 level is below 8%, and if the CO2 level is above 1%), and can be useful to control pests and diseases.

Disadvantages of storage in a controlled atmosphere include: (i) irregular ripening in some cases; (ii) the modification of the organoleptic characteristics (as a result of anaerobic respiration); and (iii) the increase, sometimes, of physiological disorders and chilling damage (Mir and Beaudry, 2003).

When the aim is to accelerate the ripening of a product, such as tomato, ripening chambers may be used, adding ethylene and keeping a proper temperature. These chambers are often used in ripening citrus (degreening).

MAP (modified atmosphere packaging) of fresh vegetables allows for isolating fresh products, with active respiration, in plastic film packages to modify the O2 and CO2 levels in the atmosphere inside the package. At the time of packaging, levels of 2–3% of O2 and 5% of CO2 are usual (Kader et al., 1989).

In addition, MAP decreases the dehydration of the product and insulates it from the external environment, limiting its exposure to pathogens and contaminants, which contributes to maintaining its quality. It is often used in fresh cut products.

The modification of the atmosphere in MAP requires active respiration of the plant tissues, on one side, and the existence of a barrier that prevents the gas exchange, on the other side. The creation of such barriers is achieved by using plastic films of a characteristic permeability (that controls the entrance and exit of O2 and CO2 into/from the package) and by means of micro-perforated plastic films (Mir and Beaudry, 2003).

In MAP, the control of temperature is essential. The decrease of water losses prevents the product becoming desiccated but in some cases may increase how much it wilts. Not all products are suitable for MAP.

A variant of MAP is partial vacuum packaging, which keeps the normal composition of the atmosphere, but at a lower than normal pressure in impermeable packages, at low temperature (Gorris et al., 1994). This system stabilizes the quality, decreasing the metabolic activity of the products avoiding the increase of undesired microorganisms.

29.2.2 Post Harvest Handling of Cut Flowers

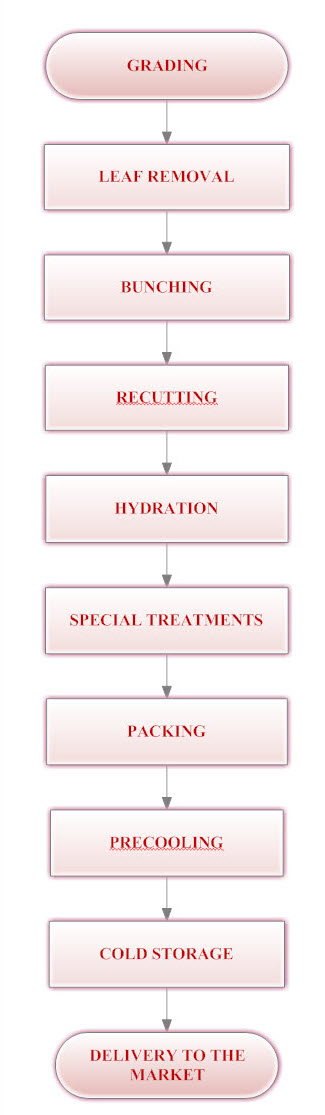

Once harvested, there are a series of steps or tasks done to prepare the flowers for market. These are collectively called handling. These handling steps include;

Not all of these steps are done to all flowers, and whether they are used or not depends on the market the flowers are going to be sold to. Where and how the steps are done depends on the market and the facilities of the operation. Flowers can have all the handling steps performed in the field, only some done in the field with the rest in the packing shed, or have all handling steps done in the packing shed.

Field handling usually is limited to leaf removal, grading, bunching, hydrating, and packing with immediate transport to market or cold storage for brief holding. Flowers for local retail markets often are packed this way since they are marketed immediately after harvest. Flowers also can have these steps performed in the field and then be transported to a packing shed where recutting, special treatments, precooling and dry packing can be performed.

All the handling steps can be done in a packing shed, too. It often makes for a better flow of activities if they are all done in the same place. Some of the steps can only be feasibly done in the packing shed, such as special treatments, precooling, cold storage and recutting. These extra steps usually are done for flowers going to wholesale markets.

The packing shed may be an ultra-modern air conditioned building or an open air covered porch. The handling space should

be shaded or covered to keep temperatures lower and prevent direct sunlight on the flowers.

be well lit so you can see well when grading the flowers.

have a clean water source for preparing harvest, treatment and holding solutions, and for use in cleaning the area.

have ample space so all handling activities can be performed smoothly, such that workers are not crossing over each other.

have a cold storage or at least a cooler, shaded place to store the flowers until they are ready for market.

have a place to prepare for harvest activities.

Although not previously listed, the first step after cutting the stem, whether you are going to handle them in the field or in the packing shed, should be to place them in water or a harvest solution. This solution may be acidified (pH 3.5), tepid water, citric acid works well, or a floral preservative. The harvest containers should be clean and disinfected after each use. Flowers should never be laid on the bare ground. After the harvest container is full of flowers, place them in a cool place until they can be handled or taken to market. The cool place can be a shady area in the field or a refrigerated cold storage. Do not over fill the containers. This will bruise your flowers and cause some to tangle with each other.

Leaves should be stripped from the stem. If the flowers are being field handled this can be done before they are placed in the harvest containers or before they are bunched into marketable bouquets. Usually, leaves are stripped from the bottom one- third of the stem, or at least the ones that would be in any holding solution.

Grading starts with deciding which flowers to harvest. Only marketable flowers should be harvested. Marketable flowers are free of blemishes, including both leaves and petals. The flowers can be grouped or graded by stem length if there are differences and also by developmental stage. More mature ones should be sold as soon as possible, while others can be held in cold storage for later sales.

How the flowers are bunched and packaged depends on the market you are using. If you are selling in a local retail market you have a lot of flexibility, but your customers will let you know what sells the best. Mixed bunches and single type bunches are both popular. Larger flowers such as lilies, gladiolus and sunflowers often are sold as single stems. Sleeving or wrapping the bunches helps prevent the different bunches and flowers from becoming tangled. Columbine, larkspur, delphinium, baby primrose, forget-me-nots and buddleia are flowers that should be wrapped or sleeved prior to marketing to prevent tangling.

Wholesale markets have a set of guidelines for the methods of bunching and packaging flowers. Most are bunched by 10‘s or 5‘s . Some, like roses and carnations, are bunched by 25‘s. Lilies-of-the- Valley are bunched in 25‘s and Sweet Violets are bunched in 100‘s with a collar of leaves underneath the flowers. Large, expensive to grow flowers can be sold by single stems. As stated before, some should be wrapped to prevent tangling. Most are boxed and shipped dry.

Proper pre-shipping handling is important in order to get flowers to the market in good shape. The flowers should be well hydrated but not wet when packed. Most spike flowers like snapdragons and gladiolus need to be packed upright to prevent the tips from curving. Special boxes or hampers are made for these types of flowers.

Once bunched, flowers should be hydrated, placed in water for a while before they are packed dry. The hydrating step should include a step where, after the flowers are bunched, the stems are recut under water to eliminate any air bubbles in the xylem that can block the uptake of water. These air bubbles can occur when the flowers were harvested. Once recut, the flower can be placed in a general holding solution used to hydrate the flowers or receive a special treatment such as silver thiosulfate. Flowers usually are not packed dry into boxes in the field but are in the packing shed for distant wholesale markets. When flowers are packed into boxes, the bunches are sleeved or wrapped and then packed tightly so the bunches do not move or vibrate in transit (causes bruising). The standard flower box is 12×12×48 inches. There are smaller sizes, too, called half or quarter boxes that are 6×12×48 inches and 6×6×48 inches, respectively.

Precooling is a step that rapidly brings the temperature of the flowers down from the field temperature to a proper storage temperature. A low temperature slows the respiration rate of the flowers which in turn helps them last longer.

Forced-air cooling is the best method for flowers cool air is actively forced with fans through the bunched flower. This can be done when the flowers are in a bucket or when they are packed dry into boxes. The precooling of flowers is a very important step for individuals selling to a large wholesale market, distant markets and if their crop is to be stored for a long time such as peonies. Individuals who sell at a local retail market usually do not need to worry about this step since their flowers will be in the customer’s home the day they are picked.

Cold storage is recommended for all flowers that will not be in the market immediately and any flowers sold wholesale. As stated before, low temperatures slow the respiration rate of the flowers and prolong the vase life of the flowers. In general, temperatures should be 32 to 40°F and have a relative humidity of 85 to 90 percent, for most flowers. Flowers should never be stored with fruits and vegetables. Some fruits and vegetables produce ethylene that can dramatically shorten the life of the flowers. Once flowers are bunched into marketable units they should be placed in cold storage. As a new grower using local retail markets, a refrigerated cold storage may not be available or affordable. Since most of their flowers will be sold within hours a cool place such as an air conditioned room, cellar or basement could be used.

Flower storage life and vase life are considered to be two different things. The customer wants to know the vase life i.e. how long would the flowers last in his home while the grower needs to know both: to determine how long flowers can be kept in cold storage and to be able to tell customers how long the flowers will last. If flowers have to be stored before marketing, a cool place (preferably a refrigerated cold storage, especially for flowers) should be used.

There are many flowers that are not commonly found in the wholesale market because they do not store well, ship well or last long. These should only be used for local markets. These include foxglove, garden phlox, lupine, clarkia, stevia, common stocks, candytuft, cornflower, feverfew, blue lace flower, English daisy, calendula, pot marigold, sweet violets and gaillardia.

REFERENCES

1. Nicolas Castilla, 2013. “Greenhouse Technology and Management.” Ediciones Mundi-Prensa, Madrid (Spain) and Mexico.PP. 243-245

2. Karen L.B., 1997. “Post -harvest handling of fresh cut flowers and plant material” Cooperative extension service, Manhattan, Kansas.