Site pages

Current course

Participants

General

Module 1:Water Resources Utilization& Irrigati...

Module 2:Measurement of Irrigation Water

Module 3: Irrigation Water Conveyance Systems

Module 4: Land Grading Survey and Design

Module 5: Soil –Water – Atmosphere Plants Intera...

Module 6: Surface Irrigation Methods

Module 7: Pressurized Irrigation

Module 8: Economic Evaluation of Irrigation Projec...

Topic 9

LESSOIN 20 Equipment for Land Grading

Land levelling involves cutting, moving and filling earth material, where cut and fill areas separated by some distance. Land levelling is performed in 5 to 10 years period.

Land grading involves smoothing of the soil surface to correct localized minor surface irregularities. Land grading is reshaping of the field surface to make field suitable to control flow of water, to check soil erosion and to provide efficient surface drainage system. In rice field, the land grading is often performed under saturated conditions with animal or machinery power.

Land grading is performed using equipment operated by animal and mechanical power. The brief descriptions of the land levelling/land grading equipments are presented in this lesson.

20.1 Equipment Operated with Animal Power

20.1.1 Animal Drawn Buck Scraper

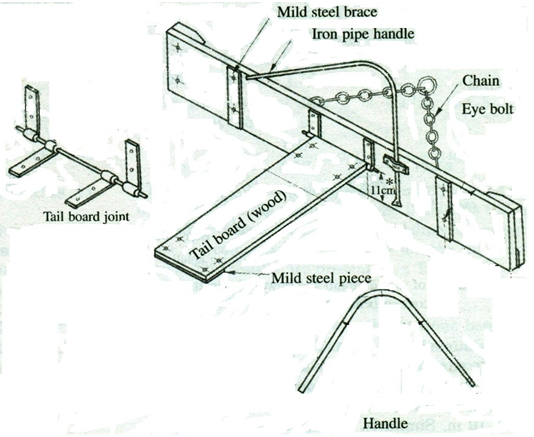

Animal drawn buck scraper is used for land grading and leveling fields of smaller and medium sizes. Buck scraper is a simple implement for land grading. The operator can control the depth of cut depends upon the load on scraper. The operator stands on the scraper board to allow deeper cut. Some time it is used to move the soil. The parts of the buck scrapers are the front board, the tail board, joints, handle and hitch. The implement has several operation features. The most important dimensions of the implement are the location of the hinge point of the tail board at the back of the front board and the position of ‘eye bolt’ or hitch of the chain on the front board. The centre of hinge pin is set at 11 cm, from the bottom of the front board (Fig. 20.1). The position of ‘eye bolt’ or hitch points on either side is set at 6.5 cm from the bottom of the front board (Michael, 2010).

Fig. 20.1. Animal drawn wooden buck scraper.

(Source: Michael, 2010)

After loading, the operator can move back and walk behind the implement, since the scraper will usually carry a full load without the operator riding or holding the handle unload, the handle is lifted and the soil load is dumped. Uniform spreading of the earth material may be done by slightly raising the handle to distribute out material in a thin layer.

20.1.2 Animal Drawn Bund Former

It is a simple implement for making bunds (ridges). It is used for preparation of ridges or bund for check basin or border irrigation. It can also be used in dry farming areas to conserve soil moisture. On steep slopes, bunds are made along the contour to prevent soil erosion during heavy rains. The implement consists of two blades, flat iron frame bent at an angle a handle attached to the frame with tie bars and wooden beam. The operator's handle is made of wood for providing better grip and convenience, and it’s attached to the frame with the help of suitable brackets. The frame is bent at an angle and has holes for adjusting the space between the blades. The profile of blades is made to a shape so that bund formed is trapezoidal and remains stable. The blades are attached to the frame with fasteners. For operation, a pair of bullock pulls the implement; the blades gather the loose soil and accumulate it in the form of bund. Fig. 20.2 shows an animal drawn bund former.

Fig. 20.2. Animal drawn bund former.

(Source: http://agricoop.nic.in/dacdivision/Machinery1/chap1b.pdf)

20.2 Equipment Operated with Mechanical Power

Mechanical power drawn equipment such as bulldozers, tractor drawn scrapers and disc ridges are used for land grading and earth forming operation. Land smoothing is done by tractor drawn land planes. The crawlers and rubber tired wheel type tractors are also used for land grading. The sizes of equipment vary and operated by medium size farm tractors to heavy crawler tractors. The crawler tractor is used for heavy earth movement and it gives greater traction on the varying ground conditions encountered in land grading. It is more capable than wheel tractor in loading an attached scraper, and for cutting and pushing of earth when equipped with dozer blade. There is a variety of equipment that is used for land shaping; each type of machine has its own capabilities and limitations. Land shaping is done with an earth moving scraper. A motor grader is used on small fields for narrow benches or where only minor grading work is needed. It is also used to shape the ridge on the downhill side of benches and the slope from one bench to another.

20.2.1 Bulldozers

A bulldozer is a specialized tractor with two additional parts; a blade and a ripper. It is used to level the ground at construction sites and in many other places. Bulldozer, consists of crawler tractors equipped with dozer blades, is frequently employed in cutting and pushing earth to short distance. They are suitable for rough grading when the haul distance does not exceed 25 meters.

Bulldozer has attachments such as rippers, brush rakes and U blades.

a) Rippers: Rippers are hydraulically operated devices that consist of one or more shanks or teeth. It is mounted on the rear of the bulldozer tractor used to remove material from the ground and remove rocks from the soil. It is also used to aerate the soil for drying or adding moisture.

b) Brush Rakes: Brush rakes are attached to the front of the bulldozer in place of the blade. It is used to clear vegetation and debris from the soil without removing the top soil.

c) U-blade: A U-blade is attached to bulldozer in place of the standard blade. The U-blade gets its name from the fact that when viewed from above it looks like a “U”. Because the blade is curved in at both edges, it will lose less soil in front of it than a standard blade and it will carry the soil for a longer distance.

20.2.2 Tractor Drawn Scrapers

Scrapers are available in a wide range of sizes. The size ranging in capacity from 1.5 m3 to 19 m3. Large size scrapers where large quantities of earth are to be moved over an appreciable distance. The carrier-type scrapers are widely used for large scale land grading operations. It consists of a bowl or bucket mounted on rubber-tyred wheels with a blade and apron across its front end for cutting, scooping and retaining soil. To load, the bowl is lowered and the apron is partly lifted. In hauling position the apron is closed and the bowl is lifted clear of the ground. To dump or spread, the apron is lifted and the load is pushed forward through the open end of the bowl by an ejector bowl. The machine cuts to grade, hauls the load for fairly long distances and spreads the soil evenly at the desired location. The capacity of carrier type scrapers range from 1 to 2.5 cubic meters. For medium size and small level levelling work the wheeled type scrapers are used. To operate such scrapers it is necessary to loosen the ground with a plough or harrow. The scrapping operation is done by pushing the soil in a short distance and dumping at a desired place.

20.2.3 Elevating Scraper

Elevating Scraper are suitable for large size farm, the 5-and 8- yard sizes can be easily handled by a 3-4 plough tractor, whereas the 11- yard size pulled by larger farm or industrial tractors is becoming increasingly popular. Their desirable feature is the ability of the PTO driven elevator to get a heaping load each time under varying depths of cut and soil textures. Also the cutting and spreading can be done evenly.

20.2.4 Bottomless Scraper

Bottomless scrappers are used as finishing equipment to obtained desired uniform surface. The two wheeled bottomless scraper is sometimes used ahead of land planning to remove surface irregularities too large to be planned and too small to be taken care of economically with a carryall scraper. This machine has number of widths that serve various purposes, including widths up to 18 feet for handling large value of earth over a short haul. Hydraulic controls facilitated cutting, dragging, and dropping the load.

20.2.5 Levellers and Floats

The levellers and floats that can be pulled by medium sized farm tractors are more important in maintaining the smoothness of levelled field than in removing small irregularities left by heavy levelling equipment. Even wooden floats or drags ensure better land preparation.

20.2.6 Crawler Tractors

A crawler tractor gives superior traction on various soil and ground conditions encounter during operations. The top speed is limited to about 5 miles per hour when pulling a scraper; it is restricted to relatively short hauls.

20.2.7 Tractor Drawn Two Wheeled Automatic Levellers

The use of automatic type levellers each year does much to improve field surfaces for irrigation. The two wheeled automatic type leveller is usually used for the fine grading of small and medium size fields. It is operated on a medium size fields by a medium size wheel tractor. The machine has an adjustable blade which is so constructed that it will drag a considerable volume of earth. Wheeled scrapers and leveller blades are frequently used for medium and small scale levelling. They are also called bottomless scrapers.

20.3 Laser Guided Land Levelling

The word “laser” is an acronym for Light Amplification by Stimulated Emission of Radiations. The lasers used agricultural land levelling and in construction or usually of the helium-neon type, producing red coloured light. Such machines are now becoming very common in agricultural operations (laying pipe lines, excavating ditches and canals and lining canals) in developed and developing countries. The laser guided system can be mounted on bulldozers, scrapers, road graders and even terracers. Some of the advantages over conventional land levelling are: time saving, little or no error, less labour, cost effective and downloading the land elevation data on laptop for land levelling design.

The laser guided land levelling consists of following components:

1) Laser Transmitter

2) Laser Sensor

3) Electronic Hydraulic Control System

1) Laser Transmitter: The laser transmitter sends a self levelled 3600 continuous laser from a tripod in the middle of work site, where a person is excavating. The laser is projected at the plane or slope desired for excavation.

2) Laser Sensor: The laser is picked up by one or more receivers that are hand held, rod mounted or equipment mounted receivers.

3) Electronic Hydraulic Control System: The laser receivers are connected to the equipments hydraulics. The signals from laser are used to control hydraulic valves. These controls are basically for controlling the desired depth of cut and tracking the elevation of the field.

References

http://agricoop.nic.in/dacdivision/Machinery1/chap1b.pdf

Jensen, M.E., Kruse, E. G., Humpherys, and Pope, E. J. (1980). Design and Operation of Farm Irrigation Systems. ASAE Monograph 3, St. Joseph, MI: 294.

Michael, A. M. (2010). Irrigation Theory and Practice, Vikas Publishing House PVT Ltd, Delhi, India: 410.

Suggested Reading

Schwab, G. O., Fangmeier, D. D., Elliot, W. J., and Frevert, R. K. (1993). Soil and Water Conservation Engineering. John Willey & Sons, Inc., New York, NY USA.,

Hargreaves, G.H. & Merkley, G.P. (1998).Water Resources Publication LLC. U.S.A / Canada.