Site pages

Current course

Participants

General

MODULE 1. PRINCIPLES AND TYPES OF CUTTING MECHANISM

MODULE 2. CONSTRUCTION AND ADJUSTMENT OF SHEAR AND...

MODULE 3. CROP HARVESTING MACHINERY

MODULE 4. FORAGE HARVESTING, CHOPPING AND HANLING ...

MODULE 5. THRESHING MECHANICS, TYPES OF THRESHES, ...

MODULE 6. MAIZE HARVESTING AND SHELLING EQUIPMENT

MODULE 7. ROOT CROP HARVESTING EQUIPMENT

MODULE 8. COTTON PICKING AND SUGARCANE HARVESTING ...

MODULE 9. PRINCIPLES OF FRUIT HARVESTING TOOLS AND...

MODULE 10. HORTICULTURAL TOOLS AND GADGETS

MODULE 11. TESTING OF FARM MACHINES, RELATED TEST ...

MODULE 12. SELECTION AND MANAGEMENT OF FARM MACHIN...

LESSON 7. FORAGE HARVESTERS, HAY CONDITIONERS

Forage harvesters

The flail type forage harvesters use free-swinging chains, hammers or knives to sever the fodder plants by beating or cutting action. At the time of plants being severed, the flails or knives travel in the same direction the machine is moving. The flail choppers do not have chopping knives to chop the material into acceptable lengths for silage. The flails are just used for severing the plants and harvested material can be blown into windrows for curing. The beating by the flails more or less conditions the hay.

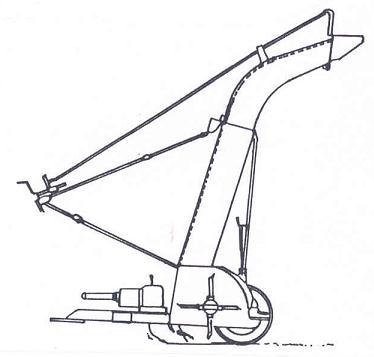

A simple flail type forage harvester (Fig. 1) can be mounted behind the tractor. Offset types of flail type forage harvester are preferred as they avoid problems associated with one set of tractor wheels running through the crop before it is cut. The degree of chopping and laceration is governed mainly by the rotor speed, partly by the relationship between rotor speed and forward speed and partly by the clearance between the flail tips and an adjustable shear bar. Rotor speed has much more effect than forward speed. Fitting two shear bars can reduce the length of chop. The machine can pick up crops fairly cleanly from a windrow.

Fig. 1: Flail type forage harvester fitted with adjustable twin-chop shear-plate.

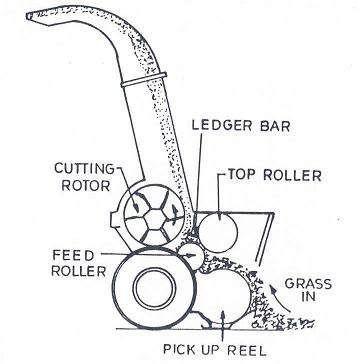

A number of forage harvesters have large diameter cylinder with multiple knives, designed to avoid serious damage of cylinder by foreign materials, by allowing individual knife to either bend or forced inward to create wide clearance between knife and shear-plate. The damaged knife can be easily replaced. The machine has simplified feed and delivery systems. One such design uses a very wide contra-rotating cylinder in conjunction with a pair of feed rollers (Fig. 2). The machine ejects the foreign matters such as small rocks and uses little energy in propulsion of the crop. Some new designs have achieved high throughput in relation to power input, partly as a result of less chopping. Electro-hydraulic systems are used on high-output forage harvesters for effective and rapid adjustment of discharge chute angle and the flaps.

Fig. 2: Forage harvester with pick-up, pair of feed roller and wide contra-rotating cylinder.

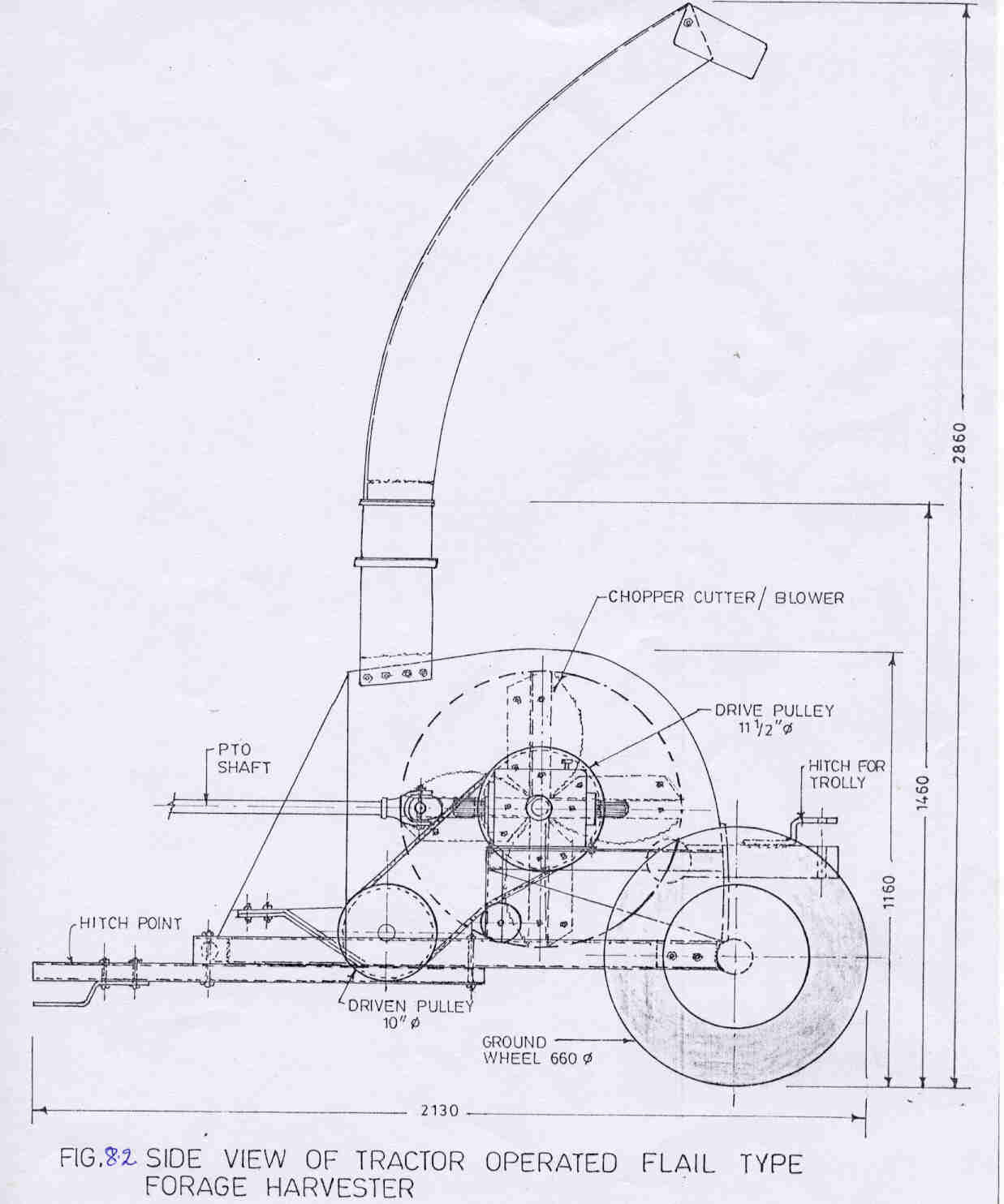

Tractor operated Flail type forage harvester cum chopper

This machine in a single operation can harvest chop and load the chopped fodder in the tractor-trailer attached to the machine. It is operated by a 26.1 kW tractor (Fig. 3). This machine in a single operation can harvest, chop and load the chopped fodder like maize, bajra, and oats in the trailer attached to the machine. It consisted of a rotary shaft on which flails are mounted to harvest the crop, auger for conveying the cut crop, cutters for chopping & conveying chopped fodder through outlet into the trailer. After the blades cut the crop, it comes in auger, which conveys it to the chopping mechanism. The chopping mechanism cuts the crop into pieces and chopped material is thrown out with a high speed and is filled into the trailer hitched to the machine. Working capacity of forage harvester is 0.2 ha/h. Weight of the machine is about 670.0 kg.

a) A view of forage harvester in field

b) Details of forage harvester in field

Fig. 3: Tractor operated Flail type forage harvester cum chopper.

Tractor operated cutter bar type forage harvester and loader

The system consisted of a two separate units. First one consisted of a mower and the second one was a chaff cutter cum loader. Both the machines are tractor operated. The mower has a working width of 196 cm and so designed that it can be folded easily during transportation. The machine cuts the fodder crops and lays in the field which is manually collected and then fed into the loader where it is chopped in to small pieces and directly loaded into the trailer. It is operated by a 26.1 kW tractor (Fig. 4). The system consisted of a two separate units. First one consisted of a mower and the second one was a chaff cutter cum loader. Both the machines are tractor operated. The mower has a working width of 196 cm and so designed that it can be folded easily during transportation. The chaffer cum loader has a cross section area 28 x13.5 cm2. It has two powered feed roller and one compressing roller. It had two chaffing blades for chaffing of fodder and six thrower attachments are being mounted on the periphery of the cutter. A reversing mechanism has also provided for safety. The fodder cut with mover and is collected in the field manually. The chaffer-cum-loader chaps the fodder at site and the throwers mounted on the periphery of the cutter throws the fodder directly into the trailer. Working capacity 0.2 ha/h for cutter and 12-18 t/h for Chaffer-cum-loader. Weight of the machine (cutter and chaffer-cum-loader) is 150 + 690 kg. Overall dimensions are:

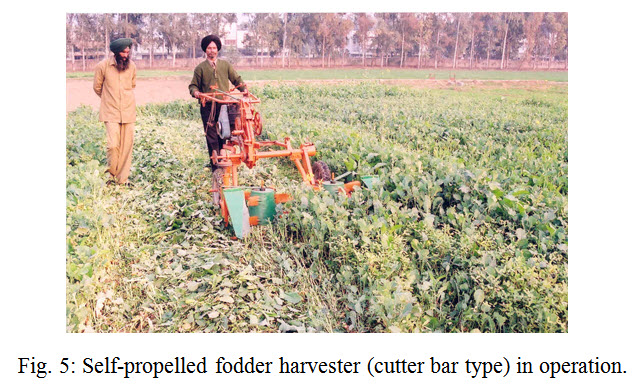

Self-propelled fodder harvester (cutter bar type)

The self-propelled fodder harvester consists of 1450 mm cutter bar (Fig. 5). It is mounted in the centre of the power transmission with the help of two side linkages made of high-pressure circular pipes to dampen the vibration of cutter bar. The unit is also provided with crop gathering drum-having flappers rotating inwards near the cutter bar. The vertical side covers around the transmission system are provided to avoid blockage of the fodder and extended vertical guides are provided for proper windrowing. The ground clearance of the machine has been increased to 480 mm to facilitate easy passage of fodder. Power to wheel is provided through extension with the help of chains and sprockets with the chassis suitably strengthened. The track width is also widened to 1040 mm and a caster wheel is provided at the rear to improve stability and maneuverability. The effective field capacity of machine is 0.1 ha/h at a forward speed of 1.5-2.0 km/h.

Self-propelled Lucerne harvester

Lucerne is perennial leguminous plant growing to a height of 60 to 90 cm. It is a forage crop generally grown in basins of size 1.20 x 6 m having a very high yielding potential under appropriate fertilizer and irrigation management. Harvesting of crop is one of the important agricultural operations, which demands considerable amount of labour because it is done manually by sickles. The cutting and laying in the windrows consume 65-75% of labour and gathering, bundle making and transport in the field involve the rest of the labour requirement. The scarcity and high cost of labour and drudgery during harvesting are the serious problem faced by the farmers. It is, therefore, essential to adopt the mechanical methods so that the timeliness in harvesting operation could be ensured and field losses are minimized to increase the productivity and production on the farm. The self-propelled Lucerne harvester consists of a gearbox and cutter bar (Fig. 6). Type of cutter bar is bi-directional reciprocating type made from high carbon steel. Length of stroke for cutter bar is 25 mm and effective width of cutter bar is 860 mm. A man can walk behind the machine with an average speed of 2 km/h. The recommended speed ratio of the average cutter bar speed to the forward speed of machine is 1.3: 1.4. Two wheels are used for transportation purpose. The ground wheels drive the reel of the harvester. Ground drive provides the desirable feature of maintaining a constant speed ratio between peripheral speed and forward speed. The reel is made up from Ø 6 mm MS bar of diameter 70 cm and length 74 cm. The speed ratio of the ground wheel to reel is 1:1. The preliminary field trials were conducted at different locations. The effective field capacity was found to be 0.113 ha/h and field efficiency was 70-75%. Thus, there is net saving of 52% in cost of cultivation and net time saving of 90%.

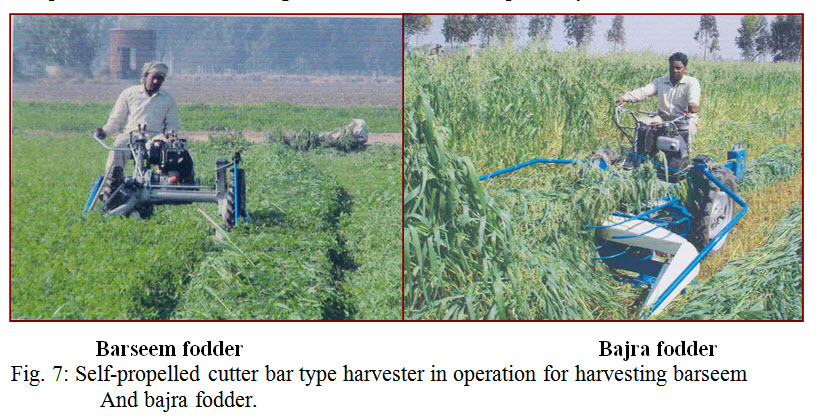

Self-propelled cutter bar type harvester for fodder crops

The machine consisted of a 10.2 hp, 4 stroke, single cylinder, air-cooled diesel engine (Fig. 7). The machine has cutter bar width of 130 cm. The power from engine has been provided to the traction wheels with the help of gear trains. The machine has four forward speeds and one reverse. The track width of machine is 1.23 m and the ground clearance of machine 41 cm. The steering of machine is done with the help of foot-operated pedal provided below the operator seat, which guides the wheel. The crop after harvesting falls behind the cutter bar and was guided with wooden sticks provided behind the cutter bar for small height/hard stem crops. But in case of tall and weak stem crops, binding attachment without twine is required to avoid wrapping of crop to cutter bar. The average field capacity of the machine for harvesting barseem and oat crop was 0.42 and 0.28 ha/h respectively, whereas the corresponding throughput of material was 6.0 t/h and 11.0 t/h. The field efficiency of machine was 66.57 % and 40.55 % for barseem and oat crop. The height of cut from the ground for barseem and oat crop was 7.0 cm and 12.5 cm but it was more near the bunds. The saving in cost of operation and labour for harvesting barseem and oat crop with machine as compared to manual harvesting was 42-44 and 55% respectively.

Hay Conditioners

The conditioning of hay by means of crushing, crimping or flailing is becoming increasingly popular with many hay-makers. It has many advantages viz. speeds up field curing and reduces drying time by 30%, reduces weather damage and field losses and conserves colour and feed value through shorter exposure and less shattering. There are three types of hay conditioners: smooth roll, corrugated roll or crisper and flail type forage harvester. The smooth rolls give continuous crushing action to hay, leaving no part uncrushed. It has two rolls of a combination of one rubber roll and another steel roll. Most rubber rolls have spiral grooves to aid in picking up the hay and feeding between the rolls. The corrugated-roll type hay conditioner is also equipped with two malleable iron rolls with tapered flutes that mesh together. Some conditioners use a fluted bar roll that presses against a smooth rubber roll. As the hay passes between the rolls, it is bent, crimped, cracked at intervals and in some cases crushed. The flail-type conditioner is a hay harvester, but it is used as a hay conditioner also. In this the shear bar is removed to reduce the cutting action. The hay is partially chopped by the swinging hammers or knives.

Separate conditioners: Separate conditioners usually pickup mowed hay from the swath, but windrowers can be put through them. The bottom roll acts as the pickup. Mower –conditioners with not over 2.75 m cuts have conditioner rolls with lengths approximately equal to the width of cut, and the hay is fed directly to the rolls from the cutter bar. Originally, conditioning ease often a separate operation, performed with a second tractor following the mower. Subsequently, mowers were made available with hitches and PTO extensions to permit pulling a conditioner behind the mower. The conditioner than picks up the swath adjacent to the one being cut.

Mower conditioners: Pull-type mower conditioner consists of a cutter bar, a reel, a pair of full-width conditioning rolls, and a deflector. The most common cutting width is 2.75 m, but widths range from 2.13 to 3.65 m. The 3.6 model have rolls 2.13 to 2.75 m long with short, auger-type cross conveyors at the outer ends of the header. The conditioned hay can be left evenly spread in a swath a little narrower that the cut or side deflectors behind the rolls can be adjusted to obtain various windrows widths and positions. Windrows cure more slowly that hay in the swath but can be straddled with the tractor and sometimes eliminate the raking operation. The cutter bar is similar to that of a conventional mower except that the guards are more pointed and slender to improve performance in tangled or lodged crops and are made in pairs to provide greater support in mounting