Site pages

Current course

Participants

General

Module 1. Introduction about design and developmen...

Module 2. Study of special design features of trac...

Module 3. Study of basic design parameters for tra...

Module 4. Selection of different mechanical power ...

Module 5. Study of tractor steering and suspension...

Module 6. Design and analysis of tractor hitch sys...

Module 7. Design of a tractor hydraulic system

Module 8. Study of electrical, electronics and gui...

Module 9. Ergonomics, controls and safety features...

Module 10. Tractor testing

Module 11. General revision

Appendices & References

Lesson 21. Importance of ergonomics in tractor and agricultural machinery design.

1. Introduction

Human engineering or ergonomics deals with the aspect of man-machine system which means engineering the product or machine to fit the operator. Ergonomics (ergo=work; nomos =laws in Greek) virtually became a field of specialization recently, because now the objective is to have maximum operational efficiency, which lead to multi-disciplinary approach. There is a slight variation between two approaches, first approach deals mainly with integration of man- machine system, whereas the second approach deals with welfare of the individual concerned. Hence, ergonomics deals with the relationship between man and his occupation and environment, particularly the application of anatomical, physiological and psychological knowledge to the problem arising thereof. Objective of ergonomics is also to achieve a rational use of human capabilities and to an optimum adaptation of the work situation to these capabilities. Ergonomics, known as Man-Machine-Environment System, deals with the machine, its operator and working environment as a complete system affecting the intended work performance. It is sometimes known as human factors engineering or human engineering. Ergonomics is the study of designing equipment and devices that fit the human body, its movements, and its cognitive abilities. It deals with the physical work environment, tools and technology design, workstation design, job demands and physiological and biomechanical loading on the body.

2. Ergonomics in Tractor and agricultural machinery design

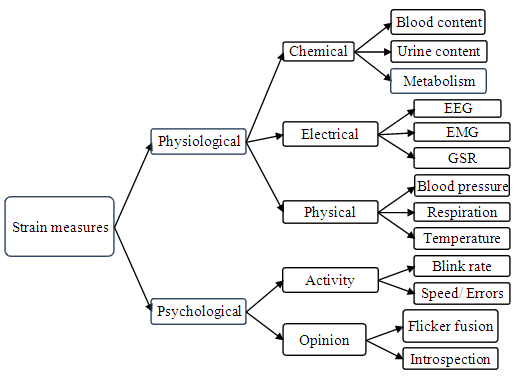

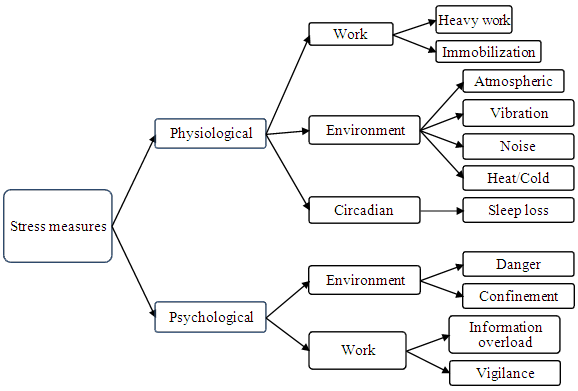

The ergonomic aspects during application in agricultural machinery are of great importance as the operator has to operate the machine in field. The physiological as well as psychological fatigue affects performance of the operator. Objective of ergonomics is not only to improve work performance but also to improve human comfort as well as safety. If ergonomic aspects are not given due consideration, the performance of the system will be poor and the effective working time will be reduced. The goal of ergonomics is to design workplace to conform to the physiological, psychological, and behavioural capabilities of workers. There are many factors acting as stress on the operator during the work. These stresses may be due to workload, immobilization for longer duration work, ambient temperature, relative humidity, vibrations, noise, dust, smoke and other gases. A feeling of chance of accident during work, space confinement, overload of information to be handled, etc. results in psychological fatigue. During the ergonomic studies, these stresses can be measured in terms of strain on the operator. The most important among physiological strains are related to heart activity, respiration, discomfort, muscular fatigue, etc. For the psychological /mental strain measurements stress on eyes, hearing loss, errors, speed of work, work performance are mostly used in studies (Fig.21.1).

3. Subjects

Whenever we have to plan for ergonomic study, subjects (operators or workers) are an integral part of the study. The objective is to eliminate the affect of individual characteristics from the rest of independent parameters and also to have an estimate of human workload during the actual work. The subjects must be medically fit and represent real user population in operation of the selected machinery. Their selection is made on the basis of gender, age and weight. Generally male subjects are selected for conducting ergonomic studies on agricultural machinery in India.

4. Physiological factors for measurements

Physical activities stimulate certain physiological responses in human beings. These responses provide basis for human energy expenditure and fatigue. The physiological measurements are made generally in terms of heart and respiration activities.

Fig.21.1. Stresses and strains in ergonomic studies

5. Heart rate

Heart rate (HR) is the most reliable dependent parameter in ergonomic studies. This is because the heart rate has a direct and linear relationship with the human workload and stress. A starting period of 2-3 minutes is sufficient for heart/pulse rate to stabilize depending upon nature of exercise. Also, care has to be taken so that the operator is not subjected to workload leading to heart rate more than HRmax i.e. the upper limit of heart rate allowed during an activity.

Here,

HRmax = 220 – age ...(21.1)

6. Respiration rate

The respiration is another basic variable in work physiology as it is linearly related to the workload. It is measured in terms of rate of volume of air inhaled or air exhaled or oxygen intake (VO2) or respiration rate. The greater the demands made on the muscle by the physical activities, the more air or oxygen is inhaled. The human energy expenditure is computed by multiplying the oxygen consumption with the calorific value of oxygen. The human workload has been categorized between light work and extremely heavy work depending upon heart rate or oxygen consumption (Table.21.1).

Table 21.1. Limits of physiological responses and work category.

|

S. No. |

Work category |

Physiological response |

|

|

Oxygen consumption (l/min) |

Heart rate (beats/min) |

||

|

1 |

Light work |

< 0.5 |

Up to 90 |

|

2 |

Moderate work |

0.5 - 1.0 |

90-110 |

|

3 |

Heavy work |

1.0-1.5 |

110-130 |

|

4 |

Very Heavy work |

1.5-2.0 |

130-150 |

|

5 |

Extremely heavy work |

> 2.0 |

150-170 |

7. Discomfort rating

Body posture is one of the major factor which causes muscular fatigue and discomfort in the body. Uncomfortable body posture in different activities reduces work efficiency, capacity and safety of operator. It is widely agreed that awkward working postures are the principle risk factor associated with muscular-skeletal injuries and disorders during occupational activities. The effect due to working posture can be measured in terms of overall discomfort rate and body part discomfort rate techniques. Table 21.2 gives the pain intensity score as measure of overall discomfort rate. The same score can be used for measurement of body parts discomfort rating.

Table 21.2. Pain intensity score as a measure of overall discomfort rating (ODR).

|

Subjective feeling |

ODR Score |

Subjective feeling |

ODR Score |

|

Comfortable |

0 |

Moderately painful |

4 |

|

Uncomfortable |

1 |

Highly painful |

5-6 |

|

Pain starts |

2 |

Very highly painful |

7-9 |

|

Slightly painful |

3 |

Extremely painful |

10 |

Psychological factors for measurements

Certain working operations need overload of information, vigilance, danger or work performance accuracy. In such conditions, there is a higher load on sensory/neuro organs of the human body. Such situations cause higher stress on eyes, hearing system, brain activity, etc. resulting in poor work performance, more errors, more missings, lesser endurance, etc. These situations sometimes may lead to headache, drowsiness and even accident. These stresses can be measured in terms of blink rate, flicker fusion, critical hearing threshold level, speed & errors in work performance, etc.

1. Anthropometry

Anthropometry is the technology of measuring various human physical traits, such as body dimensions of workers and their strength. Engineering Anthropometry is an effort to apply such data to equipment and workplace design to enhance the efficiency, safety and comfort of the operator. Anthropometric measures vary considerably due to effect of various factors viz. gender, race, age, etc. The anticipated user population, therefore, controls the application of anthropometric data. An anthropometric database, involving 79 body dimensions and 16 strength parameters, of agricultural workers is being prepared at the country level. It is critical for the designer to consider the anthropometry at the time of conception of the design rather than as a follow–up or add-on part of the design. The other application of such database is workspace and controls layout for the machinery. Table 21.3 lists a few important body dimensions and their usefulness. However, the database is to be given statistical application in terms of range, mean, standard deviation, 5th and 95th percentile values.

Table 21.3. Some important anthropometric dimensions and their usefulness.

|

S.N. |

Dimension |

Definition |

Usefulness |

|

1. |

Weight |

It is measured on a calibrated weighing scale. |

General body description. |

|

2. |

Stature |

The vertical distance from standing surface to the top of the head. The subject stands erect and looks straight-forward. |

General body description, work place designs. |

|

3. |

Vertical reach |

The vertical distance from standing surface to the height of middle finger when arm hand and fingers are extended vertically. |

Workplace layout, design of controls |

|

4. |

Eye height |

The vertical distance from standing surface to the inner corner of the eye. The subject stands erect and looks straight forward. |

Design of controls and displays |

|

5. |

Knee height |

The vertical distance from standing surface to the midpoint of knee cap. The subject stands erect and looks straight forward. |

Body linkages, work place design. |

|

6. |

Arm reach from wall |

The distance from the wall to the tip of middle finger measured with subject shoulder against the wall, his hand and arm extended forward. |

Design of controls and display panel, work place layout. |

|

7. |

Sitting height |

The height, from the sitting surface, to the top of the head. The subject stands erect and looks straight forward. |

General body description, control panel layout, work place layout. |

|

8. |

Sitting eye height |

The height from the sitting surface to the external canthus. The subject sits erect and looks straight forward. |

Display and control panel design, seat design, visual field determination. |

|

9. |

Knee height sitting |

The height from the footrest surface of the musculature just above the knee. The subject sits erect and looks straight forward. |

Work place layout, seat design, general body description. |

|

10. |

Hand length |

The distance from the base of the hand to the top of the middle finger measured along the long axis of the hand. |

Handle design, control panel design, hand tool design. |

|

11. |

Span |

The distance between the tips of right and left middle fingers when the subject’s arms are maximally extended laterally. |

Work place design, design of controls. |