Site pages

Current course

Participants

General

MODULE 1. Introduction to production of agricultur...

MODULE 2. Advance in material for tractor and agri...

MODULE 3. Advanced manufacturing techniques

MODULE 4. Heat treatment of steel

MODULE 5. Industrial lay out planning and quality ...

MODULE 6. Economics of process

MODULE 7. Techno economic feasibility of project r...

MODULE 8. Servo motors, drives and controllers

MODULE 9. CNC controllers for machine tools

MODULE 10. CNC programming

MODULE 11. Assembly and plant automation storage a...

LESSON 6. ADVANCED MANUFACTURING TECHNIQUES

1.1. Introduction

Manufacturing covers wide areas of inputs, processes and products. It reaches out to the demands in production for thousands of different varieties and types of goods. These demands range from large ships to hand drilling equipment, and from micro circuits to automobiles. The number and complexity of processes involved in the production of these goods varies drastically. The extent of alterations involved in these processes form the very basis for getting a bird’s eye view of the manufacturing activity. Some are simple primary product and some are simply transformed products such as basic metallic shapes, paint and utensils. The next are moderately transformed products such as wires, rods, metal pipes and tubes, while others are elaborately transformed products such as prefabricated metal shapes, wire products, glassware and ceramic products. The mechanization and extent to which it is involved in the process of production gives another view of manufacturing. Manufacturing covers a very wide range of situations right from robot controlled highly mechanized lines of production to some simple day to day use equipments with mechanical activities.

Thus, manufacturing industries, today, encompasses a dimension scale of more than fifteen orders of magnitudes. The design and manufacture of huge machinery, ship and spacecrafts on one side while nano and pico technology on the other side of the dimension scale, highlights the challenges ahead for engineers and technologists. With the advancement of technology newer materials, energy sources, manufacturing technology, decision-making and management techniques are being developed. These unfold lot of opportunities for the scientific and academic fraternity. At the same time, newer challenges in the form of environmental and other issues put stringent requirements on the technology. Global competition, the thrust on quality and demand for higher productivity are some of the challenges before the present industrial and manufacturing units. To survive and to succeed further, the competitors have a unique option, which is understanding of the dynamic changes that are taking place in the business environment. In view of the above, a nation should develop and update its infrastructure, such that the new and advanced technology gets into hand in hand, with the ongoing time.

1.2. Manufacturing

There are many ways and definitions available to explain the concept of manufacturing. Some of these definitions are listed below:

-

The process of converting raw materials into finished products.

-

Manufacturing is a very broad activity, encompassing many functions – everything from purchasing to quality control of the final product.

-

Chemical or Physical transformation of the materials, substances or components into some new products

-

Manufacturing is a value addition activity to the raw materials, substances/components.

-

Manufacturing is a process through which products are made through various production activities.

-

Manufacturing is the use of machines, tools and labor to make things for use or sale.

-

Manufacturing is an application of different resources such as machinery and people used for converting the materials into finished goods.

1.3. Manufacturing system

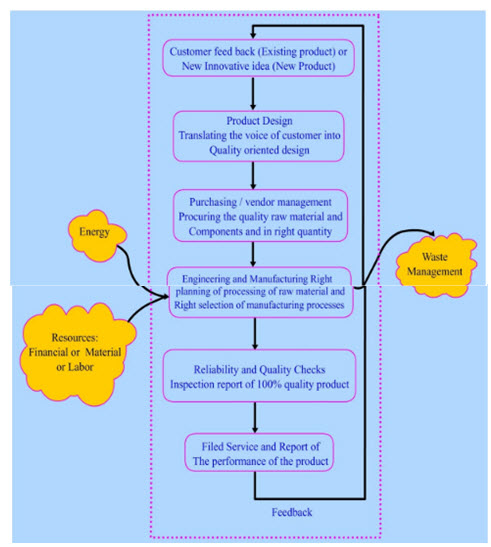

In order to consider manufacturing, as a system, we need to look beyond the conversion of raw material and processes which lead to finished products. The understanding of the manufacturing system as a whole helps in identifying which process parameters and functions of the organizations that are important. This helps to make decisions about the economical ways of producing the end products. There are several factors which are usually considered in taking a final and relevant decision about the best way of producing the desired end product. A manufacturing system can be considered as a simple input-output system at the first stage as shown in Fig. 1.1

Fig. 1.1.Input-output system

The input-output model does not provide the sufficient information about the all aspects of manufacturing. Manufacturing involves more than just processing of raw materials. The overall manufacturing system starts from the market or specifically from the customer requirements and ends when the product reaches the hands of customers. The present day trends also look beyond the delivery of the product to the customer i.e. after sale, services offered by the organization. The basic model at Fig..1.2 is further expanded to incorporate most of the functions involved in an organization for the design, planning and manufacturing of a product. The manufacturing system incorporating all the above aspects (holistic approach) as shown in Fig.1.2

Fig. 1.2 Manufacturing system boundary

1.4. Manufacturing trends

- In 1960s, the success of a manufacturing company depended on cost.

- In 1980s, the success of a manufacturing company depended on quality.

- Present day, the success of manufacturing company depends on cost, quality and lead time (lead time is time between placing the order and receiving it, alternatively, it is also known as time to market)

1.5. Manufacturing challenges

The emerging economies, the social and political transitions taking place and the new ways of doing business are changing the world dramatically. It is visualized through these trends that manufacturing environment of the future would be extremely competitive and significantly different from what it is today. In-order to remain successful in such an environment, the manufacturers needs to be updated with the latest trends and should possess dynamic capabilities, which need to be distinctly different. The main challenge for the future entrepreneurs is the attainment of such capabilities, some of which are as discussed below:

The ability to innovative ideas and to develop a creative environment for such innovations in manufacturing

Development of effective and efficient training and education programs for the manufacturing workforce, as more skilled workforce is required

The use and implementation of information technology in various areas of the manufacturing industries and their sub-functions

Sustainability of small and medium scale enterprises to provide support to the large scale manufacturing organizations

Focusing on clean and green manufacturing technologies, the environment and the society issues. The responsibility for the production process thus goes hand-in-hand with responsibility for the final disposal of products i.e. recycling in line with environmental policies.

1.6. Need of advance manufacturing technology

-

Manufacturing is the basis for all economic activities and future growth of a country

-

At the beginning of 20th century, mass production using efficient machine tools emerged in USA (Ford motors)

-

After the second world war, new / advanced manufacturing processes came into existence

-

Since 1950s, new technologies have been emerged – computerized numerical control, flexible manufacturing systems, lean manufacturing, green manufacturing, computer integrated manufacturing are some of those.

-

Newer materials have been developed and their processing requires special machine tools or special manufacturing process

-

Therefore, there is a vital need to have more efforts to continuously advance manufacturing technology for a better-off and more stable future

1.7. Manufacturing processes classification

There are six basic / fundamental classifications of manufacturing processes.

-

Metal casting or Molding: expendable mold and permanent mold

-

Metal Forming and Shearing: rolling, forging, extrusion, drawing, sheet forming, powder metallurgy

-

Material Removal Processes / Machining Processes: turning, boring, drilling, milling, planing, shaping, broaching, grinding, ultrasonic machining, chemical machining, electrical discharge machining (EDM), Abrasive flow machining (AFM), abrasive jet machining (AJM), electrochemical machining, high-energy beam machining, laser beam machining (LBM) etc.

-

Joining: welding, brazing, soldering, diffusion bonding, adhesive bonding, mechanical joining, plasma arc, plasma MIG, projection welding, ultrasonic, electron beam welding, laser welding etc.

-

Finishing (painting, anti-corrosion coatings, etc.)

-

Rapid Manufacturing: stereo-lithography, selective laser sintering, fused deposition modeling, three dimensional printing, laminated object manufacturing, laser engineered net shaping

1.8. Material removal processes / Machining (Subtractive processes)

Metal removal processes, in which we remove the excess material to give the final shape to the product, are often termed as secondary or machining processes. They are also termed as finishing processes; which are done to give the required finish or tolerance to the end product. This means that in both the cases i.e. either removal of material or finishing of part, the product to be cut or finished is made by one of the other processes described above. At instances, the product geometry is very complex, to be produced by other processes. In such cases the basic shape of the product is produced using other processes and the final shape is created by using some machining process. The major metal removal / machining processes are as given below:

Milling, Turning, Drilling

Broaching, Shaping, Planning

Honing, Etching, Grinding

Finishing Processes

Abrasive Flow Machining

Abrasive Jet Machining

Water Jet Machining

Electro Discharge Machining (EDM)

Wire Cut EDM

Electro Chemical Machining (ECM)

Ultrasonic Machining/Drilling (USM / USD) Electron Beam Machining (EBM)

Laser Beam Machining (LBM)

Electro Chemical Grinding (ECG)

Hybrid Processes

Reference: http://nptel.iitm.ac.in