Site pages

Current course

Participants

General

Module 1. Introduction to human engineering

Module 2. Human performance and responses

Module 3. Working environment and work space design

Module 4. Rehabilitation scheme and DMR Act

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Lesson 11. ARRANGEMENT AND UTILIZATION OF WORK SPACE, ATMOSPHERE CONDITION

11.1. Introduction

Human workspace can consist of many different physical situations including that of the plumber working under a stoped up sink, the astronaut in his capsule, the assembler at his position on the assembly line, the flagpole painter and the minister in his pulpit. There are millions of peoples whose work activities are carried out while seated in a fixed location. The space with in which such an individual works is sometimes referred to as the ‘work-space envelop’. This envelop should be designed on a situational basis, considering the particular activities to be performed and the types of people who are to use the space. To illustrate the types of data that would be relevant in designing specific work space envelop, however, the results of a couple of anthropometric studies will be shown.

11.1.2 Workplace and Workspace

Most workers spend a major portion of their time in a small work area, called the work space or ‘work envelop’. A work space is a three dimensional region surrounding the worker, define by the outmost points touched by various parts of the body and by the controls, tools or other equipment used by the worker. The term workplace is more comprehensive and can be as varied as assembly stations, offices, warehouses, vehicle cabs or any other area where work is performed.

11.2 Arrangement and utilization of work space:

The area for potential regulations affecting operator work space designs which is Minimum dimensions based on normal operational requirements. If the driver is to safely operate his vehicle he must first be able to fit into the cab without being forced into awkward postures. He must then be able to reach and operate all controls without undue hindrance. In essence this means that the cab needs to be designed around the operator. While we are primarily talking about minimum dimensions, it is important to note that male and female maximum dimensions must also be considered when designing for the smaller drivers.

The design dimensions of the cab interior workspace can have an impact on driver comfort and safety. If the driver has to assume cramped or awkward postures due to inadequate space, he may tend to fatigue more quickly. If there is insufficient room to operate steering wheel, foot pedals and other controls, the driver may not perform at his best. Regulations for the cab's interior should require designs which ensure a minimum safety, health, and comfort level and which reduce the severity of the deterioration in the driver's performance capability over time. A reduction in the driver's allotted space in the cab is certainly a trend in the wrong direction to achieve these objectives.

11.2.1 Factors considered in operator workplace design

Multiple factors are to be considered in operator workplace design (OWPD) on which review of literature is citied and has been presented under following heads:

Ergonomics in agricultural operations

Anthropometry in agricultural machines

Optimization of operator workplace

OWPD in relation to seat

OWPD in relation to steering wheel

Driver’s response

Operating posture

Control locations

11.2.2 Workplace layout

Proper workplace lay out requires that consideration be given to various workplace dimensions. The control and the operation being controlled must be located with due regard to :

The operator size

His position and the direction in which he can most easily look

The spaces in which he can best manipulate controls

Special influences such as protective clothing.

11.2.3. Determining the operation which the operator is controlling

Before beginning to design the workplace it is necessary to obtain preliminary information about the man-machine system. According to the nature and extent of the project a decision will have to be made on the degree of formality that is required at this stage.

11.2.4. Placing the operator so he can have optimum vision, or vision of the display

In order to plan the sensory input to the operator the principal consideration is normally to place the operator so that he can have optimum vision of the display. Where the operator is in direct control this may be the comparatively straightforward examination of the visual aspects of the task as here described.

Safety, comfort and convenience should be considered in the design, location and construction of the operator’s work place. The work place should be located on the machine so that visibility in the driving position is good without requiring the operator to work in an awkward, tiring position. Levers, pedals and instruments should be conveniently and logically located and the work place should fit both tall and short operators. In addition, the operator should be able to change his working position easily and the work area should be free of sharp edges and obstructions such as transmission cases.

Functional considerations in design of the workplace for an off-road vehicle operator are visibility, easy access to controls, and clearance. Easy access to all controls in the workplace and cab are necessary so the operator can achieve the desired machine performance and productivity. Primary visibility requires that the operator can look outside the cab in any direction, both near and far. Secondary visibility is needed to monitor instruments and controls in the workplace and cab. Clearance at various locations is necessary to provide access to and from the workplace. Proper workplace dimensions in relation to the seat are important for ease in grasping and operating controls. These factors are related to the operator’s anthropometric and biomechanical characteristics

To provide a reasonably satisfactory posture whilst driving, the limb angles should be within certain specified ranges as given in Table 11.1

Table 11.1- Range of comfort angle

|

S.No. |

Body member |

Angle (in Degrees) |

|

1 |

Back |

20-30 |

|

2 |

Hips |

95-120 |

|

3 |

Knee |

95-135 |

|

4 |

Ankle |

90-110 |

|

5 |

Upper Arm |

10-45 |

|

6 |

Elbow |

80-120 |

|

7 |

Wrist |

170-196 |

(Source: Yadav and Tiwari, 1998)

Table 11.2 - Optimum movement range for a seated operator (“b” is derived value)

|

S.No. |

Body Member |

Movement Range (in degrees) |

Comfort Range (in degrees) |

Comments |

|

1 |

Back |

- |

10-45 |

- |

|

2 |

Hips |

80-226b |

95-120 |

95-97○ for alert driving |

|

3 |

Knee |

53-180b |

95-135 |

110-120○ for pedal operation |

|

4 |

Ankle |

55-128b |

90-100 |

- |

|

5 |

Upper Arm |

55-179b |

10-45 |

For operation of steering |

|

6 |

Elbow |

38-180b |

80-120 |

For seated work |

|

7 |

Wrist |

126-277b |

- |

- |

(Source: Yadav and Tiwari, 1998)

11.3. Operating posture

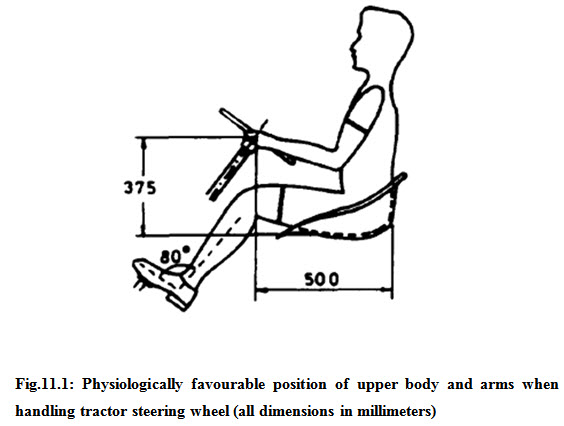

A sitting posture which results in the nearest approximation to the "normal" lumbar shape is one in which the trunk-thigh angle is about 115° and the lumbar position of the spine is supported (Keegan and Radke, 1964). Babbs (1977) described a systematic layout to define the seating package and body reference points in vehicle design, as well as to determine the adjustment envelope required to fit a range of sizes from a given population. He arranged all the body joint angles according to their suitability within the comfort range (Fig. 11.1). The optimum and maximum areas, for toe-operated and heel-operated controls, were delineated on the basis of dynamic anthropometric data. The maximum areas indicated require a fair amount of thigh or leg movement or both.

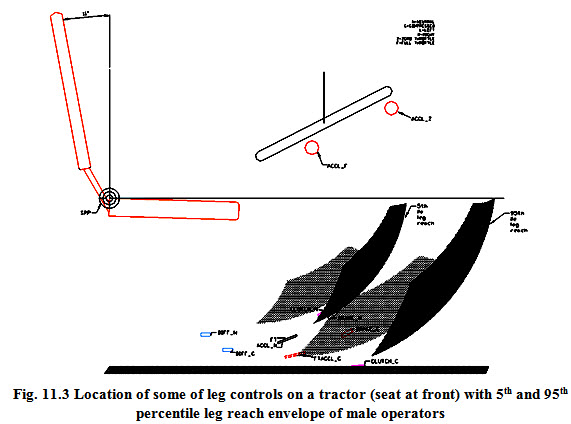

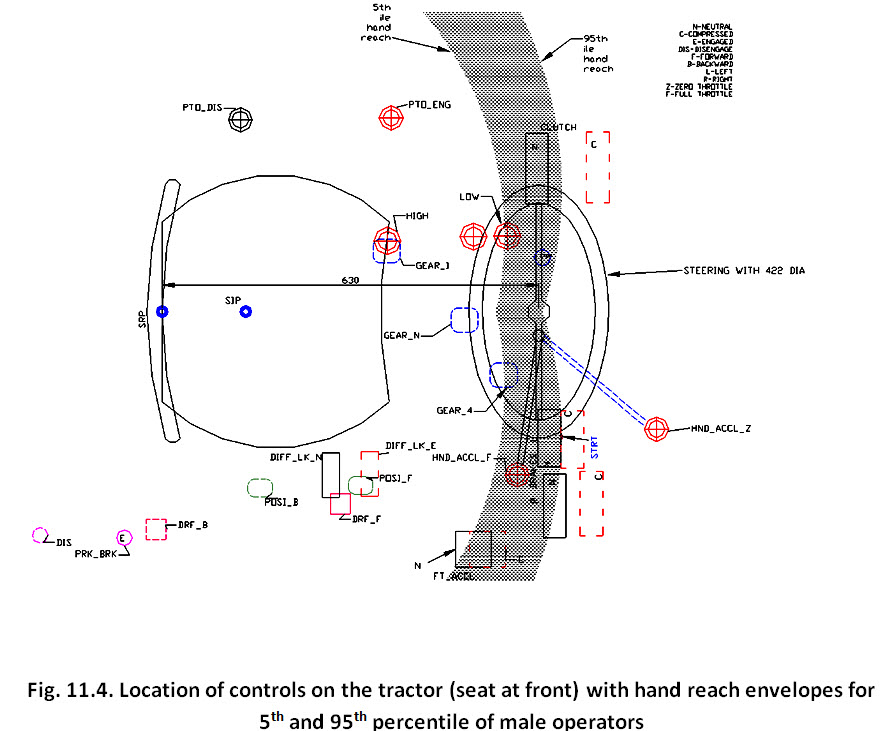

Anthropometric data of the user population are only used for proper design of the operator workplace to meet visibility and clearance requirements. Safety comfort and convenience must be considered in the design, location and construction of the operator workplace Hansson et al. (1970). Tractor operator controls within the workplace should be conveniently and logically located and the workplace should fit both tall and short operators. The seat should be designed so that, in both the forward and backward sitting postures, it provides support to the upper edge of the pelvis in order to assist rotation. To accommodate tractor operators ranging from the 5th to 95th percentile, it is easier to adjust the seat than to adjust controls; however, there must be a few compromises between hand and foot controls. The height of the seat cannot be changed greatly since, for a small person a higher seat would result in a worsened foot-pedal relationship. It is easy to provide horizontal seat adjustment with few design changes Grandjean (1988)

Research on the human – tractor interface for tractor-operator enclosures can be traced back to the 1950s in Sweden (Moberg 1973). At that time, there were a number of fatal incidents involving tractor overturns; these incidents caused strong public reaction and especial concerns among the Swedish trade organizations. In response to these concerns, researchers developed test procedures to ensure the mechanical soundness of tractor cabs and protection frames. Subsequently, researchers developed a set of the dimensions for the operator protection zone, mainly in order to simplify the mechanical test work and to minimize variations in mechanical test results. More recent design parameters – impediment of steering wheel, hand controls and protection frames for tractor drivers – were not specifically examined at that time.

11.4. The operator space envelope dimensions

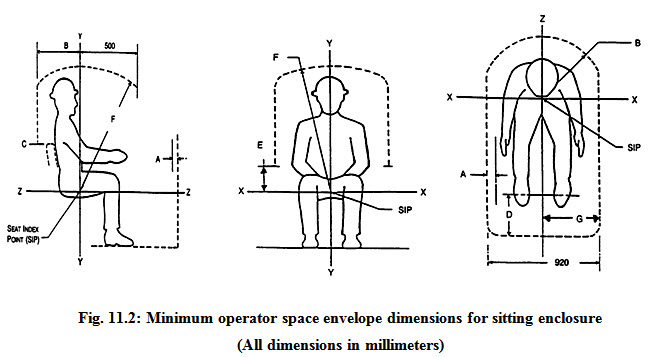

The operator space envelope dimensions as per SAE J154 are discussed in this section. This defines dimensions for the minimum normal operating space envelope around the operator for operator enclosures (cabs, ROPS) on off-road machines.

(i)The dimensions for the recommended minimum normal operating space envelope around a clothed operator are defined for a seated operator in Fig. 11.1 and for a standing operator in Fig. 11.2

(iii) The operator enclosure minimum space envelope may be smaller than specified in Fig. 11.1 and Fig. 11.2 if it can be demonstrated that the reduced operator space envelope for a particular machine application allows for adequate operator performance. Potential modifications for the operator enclosure space envelope include, but are not limited to:

Some particular types of machines may necessitate use of an operator space envelope smaller than the minimum recommended by this document. For these machines, the internal operator space envelope width may be reduced to a minimum of 670 mm to accommodate a 95th percentile operator with heavy clothing. If machine width constraints necessitate a space envelope width less than 670 mm, the space envelope may not accommodate a 95th

percentile operator with heavy clothing and the operator should be alerted that the machine may not accommodate large operators. All operators should check the space envelope width before operating the machine to insure that it is adequate.

Human body never stretches to its full arm reach limits, it can stretch to only 80% of its reach limit, at which it would be in comfort zone for operating any control. Thus, the dimensions of the cabin are ample and roomy enough to accommodate every class of operator taken under consideration. But clearance towards the rear of the seat is a prime necessity for tractor having back hoe and fitted with a swivel seat to change position and operate the controls located on the rear-end for the back hoe. Since there are very rare tractors in India with back hoe so the clearance towards the rear is relatively irrelevant from utility point of view. Even then, the clearance is enough for each and every operator. There is ample of space for leg travel towards the foot operated controls (clutch, brake and accelerator) and no operator should find any difficulty regarding this matter. Everyone should be comfortable in operating these controls with ease and would not be strained at all.

11.4.1 Spatial, Visual, and Control Requirements of the Operator

Functional considerations in design of the workplace for an off-road vehicle operator are visibility, easy access to controls, and clearance. Easy access to all controls in the workplace and cab are necessary so the operator can achieve the desired machine performance and productivity. Primary visibility requires that the operator can look outside the cab in any direction, both near and far. Secondary visibility is needed to monitor instruments and controls in the workplace and cab. Clearance at various locations is necessary to provide access to and from the workplace. Proper workplace dimensions in relation to the seat are important for ease in grasping and operating controls. These factors are related to the operator’s anthropometric and biomechanical characteristics.

11.5. Atmosphere condition

Off-road vehicles are used under varied geographic and climatic conditions. Direct exposure to temperature, humidity, wind, thermal radiation, dust, and chemicals is encountered. Table 11.3 defines comfort and bearable zones for four of these parameters as they apply to humans. Temperature, humidity, ventilation, and thermal radiation zones are interrelated.

11.5.1Climate

The indoor climate needs to satisfy several conditions if work is to be carried out in comfort. Four climatic factors (air temperature, radiation temperature of cold and hot surfaces, air velocity, and relative humidity) are significant in this respect.

Table 11.3. Environmental zones for selected parameters.

|

Environmental Parameter |

Comfort Zone |

Bearable zone |

||

|

Lower Limit |

Upper limit |

Lower Limit |

Upper limit |

|

|

Temperature, oC |

18 |

24 |

-1.0 |

38 |

|

Humidity, % RH |

30 |

70 |

10 |

90 |

|

Ventillation, m3/mm |

00.37 |

00.57 |

00.14 |

00.14 |

(Source: Sharma and Mukesh, 2010)

Design of an operator enclosure for a tractor should include thermal comfort, ride comfort, noise protection, air quality, and rollover protection.

11.5.2 Dry-Bulb Temperature

In many homes, it is common to see a thermometer placed on the wall of the entrance hall or living room. Most people are familiar with these mercury-in-glass thermometers and their use in measuring the temperature of the air. Although dry-bulb temperature indicates the thermal state of the air, other factors have an equally important effect on the heat gained or lost by a worker.

11.5.3 Relative Humidity and Wet-Bulb Temperature

One of the most important factors is the humidity or water vapour content of the air. At all temperatures above freezing, water tends to evaporate into the air, and the rate of evaporation increase with temperature. “Relative humidity” is a term used to describe the water vapour pressure of the air at a given temperature. It is the water vapour pressure at a given temperature expressed as a percentage of the saturated water vapour pressure at the temperature.

It is common in ergonomics to take three separate measurements of the air temperature. The wet-bulb temperature depends not only on the dry-bulb temperature but also on the relative humidity of the air. The wet-bulb and dry-bulb temperature can be used to calculate the relative humidity. This calculation is normally done using psychometric charts.

11.5.4 Globe Temperature

Another important measurement of temperature accounts for the effects of radiant heat. It is known as globe temperature. Traditionally, the bulb of a mercury-in-glass thermometer is placed in a metal sphere which is painted matte black. In many situations, measurements of globe temperature are essential if the true nature of the thermal environment is to be evaluated.

11.6 Thermal Comfort in Operator Enclosures

Thermal comfort is defined as the state of mind that expresses satisfaction with the thermal environment. Operator enclosure design must include cab pressurization, air filtration, air movement, heating, cooling, and window defrosting. These factors must be considered in order to provide environmentally clean air with proper air velocity and direction, temperature, and humidity for acceptable human thermal comfort. Design values suggested by Zitko (1977) provide basic guidelines for heating, cooling, air movement, cab pressurization, and air filter properties and are shown in Table 11.4.

Table 11.4. Design parameters for thermal comfort in an operator enclosure.

|

Parameter |

Rating or Capacity |

|

Heating |

8.2 kW at 66°C and water flow 11.4 L/m |

|

Cooling |

7.0 kW at 32°C and 60% relative humidity |

|

Air movement |

Three-speed blower rated at 0.236 m3/s at 50 Pa |

|

Cab pressurization |

50 to 100 Pa above outside of cab |

|

Fresh air filter |

1.92 m2 pleated paper, self-cleaning |

|

|

|

(Source: Zitko, R.F. 1977.)

11.6.1 Illumination/ Light

Light is that part of the electromagnetic spectrum which will stimulate a response in the receptors of the eye. It frequency which is usually expressed a wavelength, determines the colour of a light and its amplitude determines its intensity. The light intensity, for instance, the amount of light which falls on the work surface, must be sufficiently high whenever visual tasks have to be carried out rapidly, and with precision and ease. Apart from light intensity, differences in luminance (contrast) in the visual field are also important. Luminance is the amount of light reflected back to the eyes from the surface of objects in the visual field. Light intensity is expressed in lux, and luminance (brightness) in candela per m2 (cdm 2).

11.6.2 Air Movement and Wind Chill

In an evaluation of the effects of temperature on the worker, it is important to take air movement into account. Air movement moderates the effects of high temperatures and exacerbates the problems of low temperatures. Air movement can be measured using mechanical anemometers (in which the rate of rotation of a vane is proportional to the velocity of the air flowing through it) or by electrical means such as the hot-wire anemometer, where air movement cools a heated wire.

Avoid very humid and very dry air

Humid air (relative humidity in excess of 70 per cent) or dry air (relative humidity less than 30 per cent) can affect thermal comfort. Dry air can lead to irritation of eyes and mucous membranes, and also increases the possibility of static electricity (risk of inflammation or ignition of chemical substances, unpleasant shocks, equipment failure). The humidity can be controlled either by adding moisture to the air or by removing it.

11.6.3 Heat Stress

Heat stress may be defined as the combination of all those factors both climatic and non-climatic which lead to convective or radiant heat gains by the body or prevent heat dissipation from the body. Modern heat stress monitors make use of thermistors instead or mercury-in-glass thermometers. These devices often provide combined measurements of temperature known as heat stress indexes. The wet-bulb globe temperature (WBGT) is a commonly used heat stress index. Commercial heat stress monitors calculate the WBGT index as follows:

WBGT (outdoors) = 0.7 WB + 0.2 GT +0.1 DB

WBGT (indoors) = 0.7 WB + 0.3 GT

It should be noted that the calculation of the index of heat stress depends very heavily on the wet-bulb temperature. This fact also demonstrates why simple measurements of dry-bulb temperature alone cannot provide an accurate measure of the stress involved in working in a hot environment.

Avoid hot or cold radiating surfaces

Hot surfaces such as a roof and cold surfaces such as a cold window can affect thermal comfort. Steps must be taken whenever the radiant temperature of these surfaces differs by more than four degrees from the air temperature.

Avoid extremely hot and cold climates

Exposed parts of the skin can reach the threshold of pain in extremely hot climates or near very hot radiating surfaces. In a very cold climate, the hazard is frost-bite, the risk of which increases at high air speeds.

Effects of climate performance

Climate has a profound effect on the performance of physical tasks. It can also affect mental task performance, but this effect is thought to be indirect and due to the effects of climate on physiological variables, which themselves affect performance. There are two main theories concerning the effects of climate on performance. Climate extremes can increase the arousal level, whereas overly comfortable conditions can lower it (Meese et al., 1989). A competing theory suggests that climate extremes, particularly cold, have a distracting effect performance declines because of momentary shifts of attention away from the task toward the environment.

REFERENCES

Anonymous (1992) SAE J154.Operator workplace dimensions for off-road machines, June

Babbs FW (1977)A design layout method for relating seating to the occupant and vehicle. Ergonomics;22(2):227-234.

Grandjean E (1988)Fitting the Task to the Man. Taylor and Francis.

Hansson JE, Sjoflot Lars, Suggs, CW. (1970)Matching the farm machine to the operator's capabilities and limitations. Implement and Tractor; August 21.

Keegan J J, Radke AO (1964) Designing vehicle seats for greater comfort. SAE Journal;72:50~5.

Matthews J (1977)The ergonomics of tractors. ARC Research Review;3(3):59-65.

Meese GB, Kok R, Lewis MI, Schiefer RE, Kustner PM. 1989. Performance of a five choice serial reaction time task and an associated vigilance task in the cold. Ergonomics, SA, 1:56-67 (1989)

Sharma D.N, S Mukesh. (2010) Design of Agricultural Tractor (Principles and Problems) Eds. Jain Brothers, New Delhi.

Yadav R, Tewari V.K.. (1998) Tractor operator workplace design-a review. Journal of Terramechanics 35: 41-53

Zitko, R.F. (1977). Control center design concepts series 86 tractor. ASAE Paper No. 771049. St. Joseph, MI: ASAE.