Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lesson.16 Low Temperature Drying

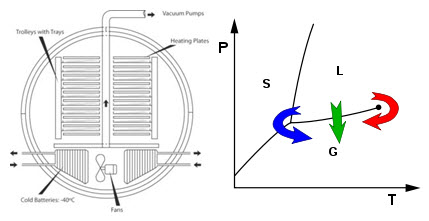

Freeze drying is a process by which a solvent is removed from frozen foodstuff or a frozen solution by sublimation of the solvent by desorption of the sorbed solvent, generally under reduced pressure.

The freeze drying involves freezing stage and sublimation stage. The foods like ginger, carrots, and ginseng are dried using freeze drying. The freeze drying parameters of the selected foods are given in Table 3. The freezing temperature ranges from -50° to -80°C and for sublimation the frozen foods are kept on heating plates having temperature 10° to 55°C with pressure less than 1 mbar. Freeze drying produces a high quality product, but being an expensive process, its application for root drying is limited. Literature shows several studies on freeze drying of carrots. Freeze dried root possess a preferable appearance, due to the excellent structural retention. Litvin et al. dried 7-10 mm thick carrot slices by combining the freeze drying with a short microwave treatment and air and vacuum drying. They first dried carrot slices by freeze drying at heating plate temperatures 30°, 45° and 55°C at 10-1 mbar to 50 % moisture content, then treated by microwaves at 637 W for 30, 40, 50, 60 and 70 s and finally dried to 5% moisture content by two drying methods namely, vacuum (45 oC for 5 h) and air (50 oC for 5 h). They concluded that during freeze drying, the rate of drying was temperature dependent and drying at lower temperature should be preferred. The sublimation process ceases at moisture content 45-50%.

Freeze-drying also known as lyophilisation, lyophilization, or cryodesiccation, is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase.

Foam Mat Freeze Drying

The high cost of operation associated with freeze drying can restricts its usage to functional foods. Foam-mat drying can be used for the functional products that can be foamed to increase the surface area to improve the mass transfer rate. Foam-mat freeze drying is one of the promising methods of drying of, which tries to utilize the advantages of both freeze drying and foam-mat drying to produce better quality functional food products like egg white powder. Muthukumaran (2007) used foam mat drying technique to prepare egg white powder. He used different stabilizers (Methyl cellulose, Propylene glycol alginate and Xanthan gum) to optimize foam stability and determined the bubble size distribution using microscopy to understand foam structure. His results showed that Xanthan gum at 0.125% provide sufficient stability for freeze drying. Also, he conducted experiments to study foam-mat freeze drying of egg white, in an effort to determine the suitability of their method. His results indicated that the addition of Xanthan Gum during foaming had a positive impact in reducing the total drying time producing excellent quality egg white powder. The addition of stabilizer also plays an important role in improving drying.

Vacuum Drying

Vacuum drying is an effective way to dry heat-sensitive foods having oxidative properties. Foods are dried in vacuum chamber having pressure less than 100 kPa at different temperatures. The heat is transferred by radiation or conduction to the product in vacuum. The lower pressure allows the moisture removal from foods at low temperature by preserving the quality. The vacuum dying parameters of carrot and ginger are given in Table 3. Madamba and Bekki [48] studied the effect of vacuum level, slice thickness and drying air temperature on final product quality and drying rate for carrots. They used slices of 1, 2 and 3 mm and drying air temperatures of 65°, 70° and 75 °C at 5, 10 and 15 kPa vacuum pressures. They found that final moisture content is affected by all the variables, average drying rate is affected by thickness while overall acceptability of product by pressure and thickness. The optimum drying conditions of 68 °C and 10 kPa for drying 1.6 mm strips were established by them.