Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lesson 40. Storage Of Cereal Grains

Compared with fruits and vegetables, cereal grains are extremely amenable to storage for the reason that their moisture content at harvest is relatively low and their bio-composition is such that bio-deterioration is much slow. Harvesting is seasonal but the need for fresh cereal products is continuous. The least requirement for storage, therefore, is for the period between harvests. Under appropriate condition, this can easily be met and indeed storage for many years without serious loss of quality is possible. Even in biblical times long periods of storage were apparently achieved.

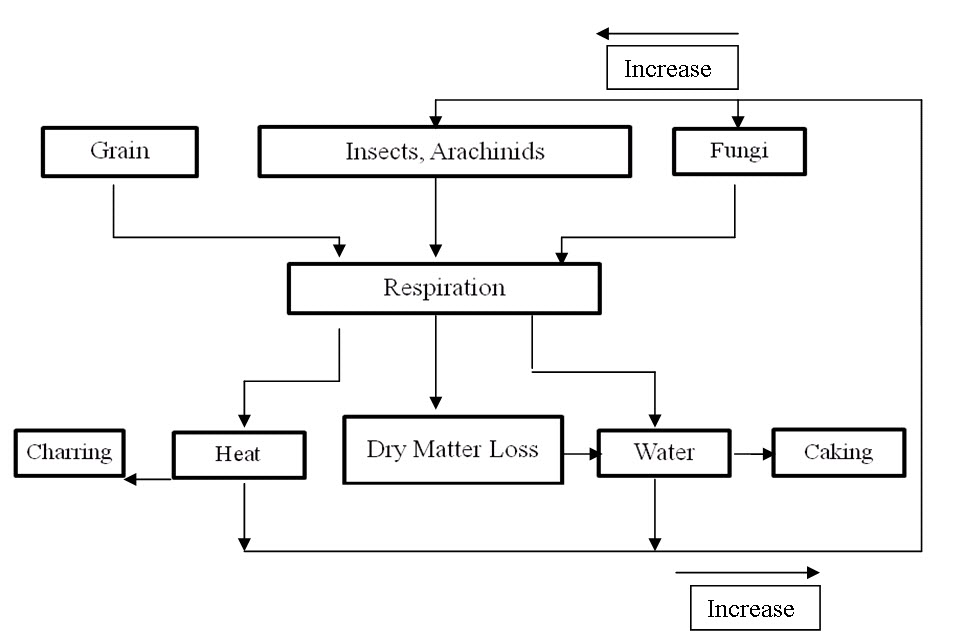

Fig. 40.1 Factors responsible for damage of grains during storage

In spite of the diversity of cereal grain types and the ambient conditions throughout the cereal producing and consuming world the hazards of storage are fundamentally similar although the relative difficulties involved in their avoidance vary with location. Successful storage method range from primitive to highly sophisticated.

The hazards besetting cereal grain storage are:

excessive moisture content

excessive temperature

Microbial infestation

insect and arachnid infestation

rodent predation

bird predation

biochemical deterioration

Mechanical damage through handling

The complexity of storage problems results from the matrix of interactions of the various hazards. They are considered separately in the text but their combined effects some of which are shown in fig, should be borne in mind throughout.

40.2 Moisture content and storage temperature

Moisture content is expressed as a percentage of the grains' wet weight. The safe moisture contents for storage varies according to the type of cereal but it is widely assumed that they are equivalent to the equilibrium moisture content of the respective grains at 75% RH and 250C and is shown below in table 40.1 for some of the cereals.

|

Cereal types |

Moisture % |

|

Barley |

14.3(25-28 0C) |

|

Maize |

14.3 |

|

Oats |

13.4 |

|

Rice |

14.0 |

|

Ryes |

14.9(25-28 0C) |

|

Sorghum |

15.3 |

|

Durum Wheat |

14.1 |

|

Red Wheat |

14.7 |

|

White Wheat |

15.0 |

Table 40.1 Equilibrium moisture content of grains at 75% RH and 250C

In temperate regions the moisture contents at which grain is stored are closer to those described as wet rather than dry. The significance of moisture contents cannot be considered alone as the deleterious effects of excessive dampness are affected critically by ambient temperature and the composition of the surrounding atmosphere. The increase in relative humidity of the interseed atmosphere with temperature is slight. It amounts to about 0.6-0.7% moisture increase for each 100C drop in temperature.

Broken grains are almost always present to some extent as a result of damage during harvesting and transferring to sound clean samples. In broken grains endogenous enzymes and their substrates, kept separate in the whole grain can achieve contact and lead to necrotic deterioration. Endosperm and embryo are exposed to moisture, micro-organisms and animal pests whereas in the whole grain they arc protected by fruit coat, seed coat, and possibly husks. Impurities can also reduce storage time in that weeds present in the crop ripen and dry at a different rate from the crop itself. Hence, still green plant material - with relatively high moisture content - can carry excessive moisture into store even when mixed with dry grain.

40.3 Changes during storage

40.3.1 Respiration

In a natural atmosphere gaseous exchange will occur in a stored cereal crop. This is due to respiration and it involves depletion in atmospheric oxygen and an increase in carbon dioxide with the liberation of water, and energy (as heat). Respiration rates measured normally include a major contribution from micro organisms that are invariably present at harvest; nevertheless even ripe dry grain, suitable for storing, contains living tissues in which respiration takes place, albeit at a very slow rate. The aleurone and embryo are the tissues involved and like other organism present, their rate of respiration increases with moisture content and temperature.

Respiration is a means of releasing energy from stored nutrients (mainly carbohydrates) and a consequence of long storage is a loss of weight. Respiration can be reduced by artificially depicting the oxygen in the atmosphere.

40.3.2 Germination

Germination of grain is an essential and natural phase in the development of a new generation of plant. It involves the initiation of growth of the embryo into a plantlet, Roots develop from the redicle and leaves and stern develop from the plumule. Hydrolytic enzymes are released into the starchy endosperm, and these catalyze the breakdown of stored nutrients into soluble form available to the developing planet.

Deterioration results from loss of weight due to enzyme activity and a loss of quality resulting from excessive enzyme activity in the products of processing.

40.3.3 Microbial infestation

Fungal spores and mycelia, bacteria and yeasts are present on the surfaces of all cereal crops. During storage they respire and given adequate moisture temperature and oxygen, they grow and reproduce, causing serious deterioration in grains.

Field fungi thrive in a relative humidity (RH) of 90-100% while storage fungi require 70-90% RH.

As with other spoilage agents dependent upon minimum moisture content, fungi may be a problem even when the overall moisture in the store is below the safe level. This can result from air movements leading to moisture migration. Unless temperature gradients are extreme the exchanges occur in the vapour phase; nevertheless, variations in moisture content up to 10% within a store are possible.

40.3.4 Insects and Arachnids

Insects that infest stored grains belong to the beetle or moth orders; they include those capable of attacking whole grain (primary pest) and these that feed on grain already attacked by other pats (secondary). All arachnid pests belong the order Acarina (mites) and include primary and secondary pests. Most of the common insects and miles are cosmopolitan species found through out the world where grain is harvested and stored. Insects and mites can be easily distinguished as arachnids have eight legs and insects, in their most conspicuous form have six.

|

Common name |

Family |

|

Grain (or flour) mite |

Acaridae |

|

Rust red grain beetle |

|

|

Lesser grain borer |

|

|

Grain weevil |

|

|

Rice weevil |

|

|

Maize weevil |

|

|

Angoumois grain moth |

|

Table 40.2 Alphabetical list of Primary Insects and Arachnid pests

Those insects listed in the table 40.2 are considered major pests. They are particularly well adapted to life in the grain bin and are responsible for most of the insect damage to stored grain and cereal products. Minor pats occur mainly in stores in which grain has started to deteriorate due to other causes while incidental pests include those that arrive by chance and need not even be able to feed on grains. Among the major primary pests five species develop inside grains weevils (grain, rice and maize) by egg inside while lesser grain borers and Angoumois grain moths deposit eggs outside but their newly hatched larvae promptly tunnel into grains. The presence of the insect and the damage it causes may not be evident from outside even though only a hollow bran coat may remain. Detection by means of soft X-rays is possible.

40.4 Damages by insects and mites

A serious grain loss due to consumption of grain by insects and mites occurs only after prolonged storage under suitably warm conditions. They are most serious in hot climates. Other problems caused by insect include creation of hotspots around insect populations where metabolic activity leads to local heating. Moisture movements and condensation in cooler areas results in caking and encourages fungal infestation.

Introduction of insects and mites from wheat stores to flour mills can cause serious deterioration in the products. Mite excreta taint Flour with a minty smell and hairs from the animals' bodies can cause 'Skin and lung disorders in workers handling infected flour. Silk from the larvae of the Mediterranean flour moth webs together causing agglomeration of grains and blockages in handling and processing equipment. In tropical countries termites can weaken the structure of a store, leading its collapse.

40.4.1 Vertebrate pests

The principal vertebrate pests to cereal stores are rodents and birds. In many countries the three main rodent species involved are:

Rattus norvegicus : the Norway common or brown rate.

Rattus rattus : the roofs, ships and black rat;

Mus musculus : the house mouse

Apart from consuming grams, particularly the embryo of maize, rodent causes spoilage through their excretions which contain micro-organisms pathogenic to man. These include salmonellosis murine typhus, rat-bite fever and wail’s disease. Rodents also damage stores structural elements, containers, water pipes and electric cables.

In well-managed stores access by rodents is denied and good housekeeping practice such as removal of grain spoilages, maintenance of uncluttered surroundings and regular inspections, prevent problems. The same is true of birds. These are serious pests only when access is easy, as for example in hot countries where grain may be left to dry in the sun. Damage to drains and blockage of pipes by nests con give rise to secondary storage problems through promoting local dampness in some stores.

40.5 Design of Storage Facilities

The requirements of long term safe storage are protection against dampness caused by weather or other sources, micro-organisms, destructively high temperature, insects, rodents and birds Objectionable odours and contaminants and unauthorized disturbance. Clearly the simplest stores such as piles on the ground, unprotected, are suitable for short periods only. Other simple stores, system is suited to cob maize rather than threshed grains, as adequate space for air movement within the store is essential. Clearly the requirements of ventilation and exclusion of insects are not immediately compatible and hence careful design is essential.

Storage of maize as cobs practised now largely by small scale growers producing for the requirements of the local community. It was at one time adopted more widely even in highly commercial practice, much small gram cereals were stored unthrashed in ricks.

In the commercial context store are needed for three purposes:

1. Holding stocks on the farm prior to sale.

2. Centralization before distribution or processing during the year following harvest.

3. Storage of annual surpluses over a longer period.

Farm stores may consist of any available space that will keep out the elements. The facilities for protection against mould and pests are very variable. Stores range from small wooden enclosures in the barn to round steel bins holding 25-80 tonnes, to sues of larger capacities. Good on- farm storage facilities allow farmers to choose the time to sell, to receive the best prices. It is sometimes necessary to provide storage for grain beyond the normal capacity of an elevator facility or elsewhere. In such conditions a relatively inexpensive expedient is the flat store. This is little more than a cover for a pile of dry grain adopting its natural form as poured. Such a form is described by the angle of repose. In the case of wheat the angle is 270 to the horizontal, hence flat stores have roofs close to this angle, Very temporary stores may make use of inflatable covers.

Flat stores are easy to fill but, as they have flat floors, removal of stocks is more difficult, usually requiring the use of mechanic shovels. In contrast, silos usually have a floor formed like a conical hopper whose walls make an angle greater than 270 to the horizontal. Piles created by grains falling freely from a central spout are not uniform as whole grains tend to roll from the apex down the sloping surfaces. Small impurities and broken grains roll less readily and thus become trapped in the central core of the pile. Such a core is described as the spout line. As the interstices can grains rolls readily and thus become trapped in the central core of the pile. Such a core is described as the spout line. As the interstices can amount to 30% of the occupied space, fines in the spout line can reach that level. Because air circulation and hence heat loss is prevented, the spout line can be associated with early deterioration through overheating. The diameter of the spout line is proportional to the width of the bin.

Also in contrast to tall tower-like stores, flat stores require little strength in the side walls. In a silo much of (he pressure of the column of grain is borne not by the floor but by the side walls. This is because each grain rests on several grains below it so that some of the weight is distributed laterally until it reaches the walls and, by friction, rests on them. In all stores some settling occurs and this varies according to the cereal type. Wheat is relatively dense and settling may be only 6% of volume but oats may pack as much as 28%. Settling is a continuous process arising in pan from the collapse of hulls, brush hairs embryo tips etc.

40.6 Control of Pests in storage

Deterioration in store is less likely if care is taken to ensure that the grain is in a suitable condition for storing, Criteria for the latter include suitably low moisture content, a low mould count and freedom from insects. Wheat containing live insects can be sterilized by passage through an entoleter, run at about 1450 rev/min. Hollow grains and insects may be broken up and can be removed by subsequent aspiration

The store itself should provide protection from weather (particularly wet) and intrusion by insects and rodents. High temperatures are undesirable and variation should be reduced to a minimum as this can lead to local accumulation of moisture. All spoilage agents depend upon respiration and hence a depletion of oxygen inhibits their as this can lead to local accumulation of moisture. All spoilage agents depend upon respiration and hence a depletion of oxygen inhibits their proliferation and activity. To achieve this it is necessary to provide a seal around the grain and a minimal headspace. In a sealed store oxygen depletion can be achieved by natural or artificial fans, Natural depiction results from respiration which in most organisms consumes oxygen and produces carbon dioxide. Artificial atmosphere control comes about by flushing of interstitial and head spaces with a gas other than oxygen. Usually nitrogen or CO2 as these are relatively inexpensive. Complete removal of oxygen is not possible.

Seated conditions are unusual and prevention of spoilage in many cases depends upon careful maintaining of the stored grains' condition, and prophylactics treatments with chemicals. Fortunately, nearly all threats to grain quality cause temperature rises and monitoring of temperature, through incorporation of thermocouples, can reveal a great deal about condition.

Forced ventilation can reduce temperatures but it may be necessary to remove the cause by use of chemical treatments. Such treatments are relevant primarily when the problem is caused by insects. Because of the possible persistence of pesticides on cereals, their use in stores is increasingly becoming regarded as a last resort. In most countries strict codes of practice apply to their uses.

Pesticides used to control insects, during storage of cereal grains, are of two types. Those that are designed as a respiratory poison and are hence applied as gas or volatile liquid, are described as fumigants. Those designed to kill by contact or ingestion arc described as insecticides. They may be applied in liquid or solid form.

Of the gascous fumigants, methyl bromide and phosphine (PH) are the main examples. Examples of 'liquid' fumigant are mixture of 1,1 dichloroethane and tetrachloromethane although the most effective fumigant is methyl bromide, this gas does not penetrate bulk grain well and the use of a carrier gas such as tetrachloromethane is an alternative to the fan-assisted circulatory system required if methyl bromide is used alone. Few stores have the necessary fans.

The period of treatment required depends upon the susceptibility of the species of insects present to the fumigant. For example three day exposure to phosphine may eliminate the saw-toothed grain beetle but six days at low temperature may be needed to kill the grain weevil. A liquid-' fumigant penetrates bulks well. The proportions need to be adjusted to suit the depth of the grain stored. Up to three metres deep a 3: 1 mixture of 1, 2 dichloroerhane: tetrachlcromethane is suitable but for penetration to a depth of 50 m equua1 proportions are needed. Fumigation requires the stores be sealed to prevent escape of the toxic fumes.

References:

1. Chakraverty, A. Post Harvest technology of cereals, Pulses and oilseeds. Oxford and IBH publishing Co. New Delhi.

2. Michael, AM and Ojha, T.P. Principles of Agricultural Engineering (Vol-I), Ed. Jain Brothers, New Delhi.

3. K. M Sahay and K.K. Singh. Text Book of Unit Operations of Agricultural Processing, Vikas Publishing House pvt ltd.