Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lesson 42. Hermetic And Frozen Storage

42.1 Introduction

Hermetic storage (HS) technology has emerged as a significant alternative to other methods of storage that protect commodities from insects and molds. This technology, also termed as sealed storage or airtight storage or assisted hermetic storage, is a form of bio-generated modified atmosphere (MA). HS is based on the principle of generation of an oxygen-depleted, carbon dioxide-enriched interstitial atmosphere caused by the respiration of the living organisms within the ecological system of a sealed storage. Among the advantages of hermetic storage is the generation of a MA in an environmentally safe and sustainable manner eliminating the need for chemical treatments, fumigants, and climate control.

42.2 Hermetic Storage Technology

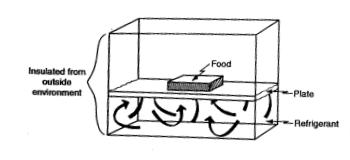

Fig. 42.1 Hermetic storage for grains

Successful use of hermetic storage is based on the need to achieve one or more of the three following goals:

Low oxygen, high carbon dioxide atmosphere to prevent infestations (molds and insects), and oxidation

Preventing entry of moisture from surrounding atmosphere

Protection from rodents

42.2.1 Low Oxygen Modified Atmosphere

Creation of sufficiently low oxygen elevated CO2 MA protects from insects, molds, and oxidation effects. This is done through a natural metabolic process of insect respiration and, in some cases the respiration of the commodity itself. When a level of less than 2% oxygen is reached mortality of all insect stages is achieved rapidly. Because insects lower their metabolism at low temperatures, a prerequisite for achieving insect mortality due to insect respiration is to have sufficiently high temperature inside the enclosure, typically room temperature of 22°C or above. The time required for insect mortality depends strongly on temperature. This is true even in the case of cocoa beans and rice, where the consumption of oxygen by both the organisms and urethe commodity, with their release of CO2, play a major role. In a few commodities, of which coffee is an example, oxygen levels don’t go down significantly because of a generally low level of infestation and the behavior of the commodity itself, but the control of moisture content is the vital element in maintaining quality.

42.2.2 Prevention of ingress of moisture

By preventing the entry of water vapor into a hermetically sealed container, adequately dried commodities are protected from external humidity, preventing a rise in their moisture content beyond their critical moisture level.

42.2.3 Protection from Rodents

Properly designed hermetic storage is highly rodent resistant. Rodent resistance is provided in the case of large hermetic enclosures such as Cocoons by using tough, slippery materials such as flexible PVC (typically 0.83 mm thick), and tensioning straps, which prevent rodents from getting a tooth hold.

42.3 Applications of Hermetic Storage

The applications for which hermetic technology has been most widely accepted are:

Long-term storage of cereal grains, primarily rice, corn, barley, and wheat.

Long-term storage of a variety of seeds to preserve germination potential and vigor.

Quality preservation of high-value commodities, such as cocoa and coffee.

In addition, still newer applications for HS are emerging, such as safe storage of high-moisture corn; storage of specialized, difficult to store products such as brown rice, rice bran and basmati rice; and the prevention of growth of toxinogenic aflatoxins in corn and peanuts, or ochratoxins in coffee. HS is also used to store oily commodities such as cottonseeds or peanuts to prevent the growth of free fatty acids (FFAs), and resulting rancidity.

42.4 Frozen Foods

The freezing of foods has become very popular and effective method of preserving foods of certain types. The basic principles involved in freezing are to inactivate the living micro-organisms causing decay or to change the liquid water present in foods into crystals of ice rendering the food as if it would have been dried. Some of the most important applications of refrigeration equipment are found in connection with the preservation of foods by freezing, cold storage of foods (and other materials) and the distribution of foods by refrigerated haulage equipment. Sharp freezing offish and poultry has been in use since about 1865 A.D.

42.4.1 Sharp Freezing: Sharp freezing consists of placing foods in a cold room with temperatures maintained from -15 to -28 0C. No provisions are made for air circulation. This is a relatively slow process and is not as much used today as it once was. It is, however, still used for freezing boxed poultry, fish, packaged meat and some cold-packed fruit.

42.4.2 Quick Freezing: Commercial quick freezing came into use around 1929 A.D. Foods may be quick frozen by four different methods:

Freezing by direct immersion in a refrigerating medium: Foods are frozen by contact with chilled brine or special sugar solutions held at - 18°C.

Freezing by indirect contact: Foods are frozen by contact with a metal surface which is cooled by a refrigerating medium such as brine. Automatic machines have been designed to continuously contact various foods with hollow plates or shelves cooled by a refrigerating medium at temperatures from -28 °C to -45°C.

Fig 42.1 Schematic diagram of indirect contact freezing system

3. Freezing in a blast of cold air: Foods are frozen on a conveyor belt moving through a tunnel freezer in which air at temperatures from -18°C to -62 °C is blown in the opposite direction

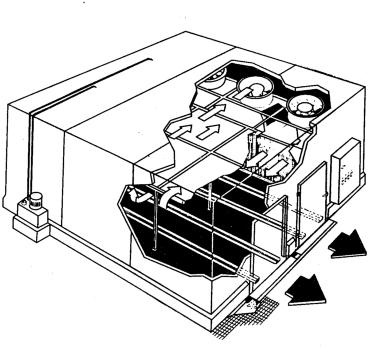

Fig. 42.2 Continuous air blast freezing system

4. Fluidized bed freezing: Here the blast of cold air is blown upwards through a bed of food to be frozen. Thus the blowing cold air creates the bubbling effect on food which remains suspended and exposed to the air blast resulting it to be the frozen food.

Besides there are other methods like plate freezing. Ice box freezing etc. are also employed for quick freezing of foods. Foods packed in cartons or wrapped in thin films can be frozen by maintaining -35°C temperature. Once the food is frozen, the required low temperatures are to be maintained during the entire period of its storage prior to consumption.

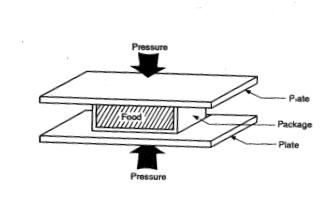

Fig 42.3 Schematic illustration of plate freezing system

Conventional halocarbon condensing units may be used in quick freezing where temperatures below about -40 °C are not required. For lower temperatures, multi-stage equipment may be used. Conventional ammonia compressors may be used at still lower temperature about -68°C.

Even though, bacterial activities come to stand still after the freezing of food has been done, yet there are few enzymes which remain active. To overcome this problem, the food (particularly the vegetables) may be blanched by boiling water or low pressure steam before freezing it by one of the above mentioned methods of freezing.

42.7. Cold Storage

Cold Storage is a special kind of room, the temperature of, which is kept very low with the help of machines and precision instruments. India is having a unique geographical position and a wide range of soil thus producing variety of fruits and vegetables like apples, grapes, oranges, potatoes, chillies, ginger, etc. Marine products are also being produced in large quantities due to large coastal areas. Keeping in view the growth rate of population and demand, the production of perishable commodities is increasing every year. The cold storage facilities are the prime infrastructural component for such perishable commodities. Besides the role of stabilizing market prices and evenly distributing both on demand basis and time basis, the cold storage industry renders other advantages and benefits to both the farmers and the consumers. The farmers get opportunity of producing cash crops to get remunerative prices. The consumers get the supply of perishable commodities with lower fluctuation of prices.

Fig. 42.2 Cold storage of Potato

Refrigerated warehouses for cold storage of foods and other products area cooled by a number of different methods:

In the direct expansion method, the refrigerant is expanded directly in coils located either in the cold storage room or directly above it.

In the brine circulating system, brine is chilled in brine coolers and then circulated through cooling coils in the storage space. This system prevents any danger of food contamination by leaking refrigerant (if ammonia is the refrigerant). Another advantage is the reserve cooling capacity of large amounts of brine if the refrigerating equipment must be shut down.

An indirect air circulation system has been more recently developed. Its use permits a more rapid change in temperature and the control of humidity. The cooling of air in such a system is done by blowing air over expansion coils, brine coils or through a spray of brine or water. The air can be dried or wetted, depending on whether low or high humidity is desired. Unit coolers or diffusers, consisting of the cooling coils, air circulating fan and a defrosting arrangement are often used to direct cold air over the desired areas.

A number of different compressor combinations are used in cold storage applications. These are most often designed for ammonia or carbon dioxide service.

- Two compound reciprocating compressors with clearance pockets (for capacity control), one for low temperature brine and the other for higher temperature brine are used. A third spare unit is usually provided.

- Smaller plants employ a compound reciprocating compressor with one end on low temperature brine service and the other end on higher temperature brine. A similar unit can be used as a spare.

- In larger plants, it is often preferable to use several small compressors instead of one large compressor. This will provide more flexibility in handling varying refrigerating loads.

References:

-

De Lima, C.P.F., 1990. In: Calderon, M., Barkai-Golan, R. (Eds.), Airtight Storage: Principle and Practice in Food Preservation by Modified Atmospheres. CRC Press, Boca Raton, Pp 9-19.

-

Diep Chan Ben, Phan Van Liem, Nguyen Tam Dao, M. Gummert and J.F. Rickman., 2006 IRRN Best Article Award, Agricultural Engineering.

-

Michael, AM and Ojha, T.P. Principles of Agricultural Engineering (Vol-I), Ed. Jain Brothers, New Delhi.