Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 10. Fluid flow behavior

Rheological tests express stress–strain relationships and study of strain rate dependency. Ideal solids deform in an elastic Hookean manner, while ideal liquids flow in a viscous medium.

Newtonian manner; in each case the behavior is independent of the strain rate. Nonetheless, foods are strain-rate dependent. They usually contain some solid and liquid attributes and, rheologically, are termed viscoelastic bodies. In addition, many possess structural elements that “yield” or rupture when forces are applied, thus changing the stress–strain behavior not only with the applied rate of strain, but also with the applied amount of strain. Foods are anisotropic in nature and their mechanical properties may vary in the direction of the stress application.

Different mechanical situations define how stress can act on a food: static (constant stress or strain), dynamic (varying stress or strain), or impact (stress exerted and removed after a very short period of time). Impact during mechanical handling is the most common cause of mechanical damage to foods. Behavior under static or dynamic stresses governs the extent of potential mechanical injury (for example, during hopper storage or discharge) and can provide valuable information on the design of handling machinery. In cases like these, definitions of creep (when constant stress is applied to a body increasing in strain as a function of time) or stress relaxation (when constant strain is applied to a body) play a role. Solid foods are mechanically characterized by compression tests or impact tests. Universal testing machines give curves of normal force versus deformation, shear forces, creep, and stress relaxation measurements.

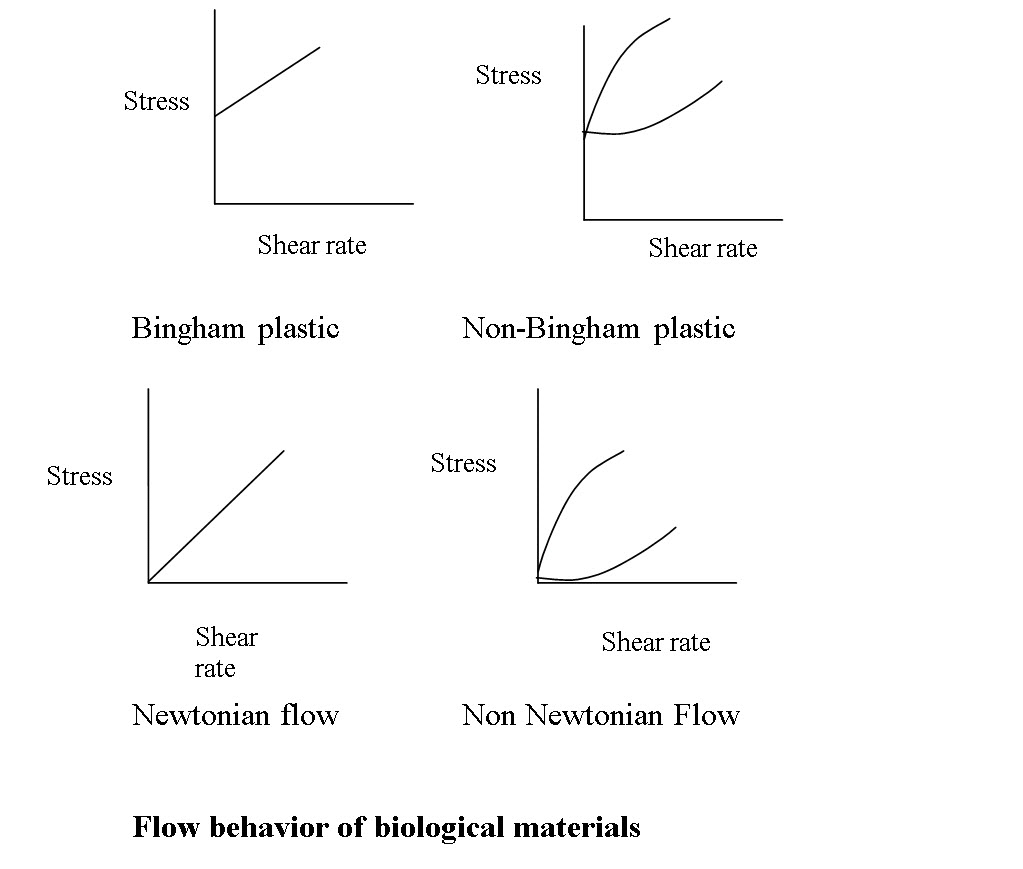

The most important mechanical-rheological behavior of fluid or viscous foods is the flow behavior, which can be basically defined as Newtonian, pseudoplastic, and Bingham, indicating viscosity of the material and its dependence on shear rate. In processing, flow properties can influence pumping requirements, flow of fluid through pipes, or even extrusion properties. Flow properties can be determined using any variety of available rheometers or viscometers.

Knowledge of the rheological and mechanical properties of various food systems is important in the design of flow processes for quality control, in predicting storage and stability measurements, and in understanding and designing texture.

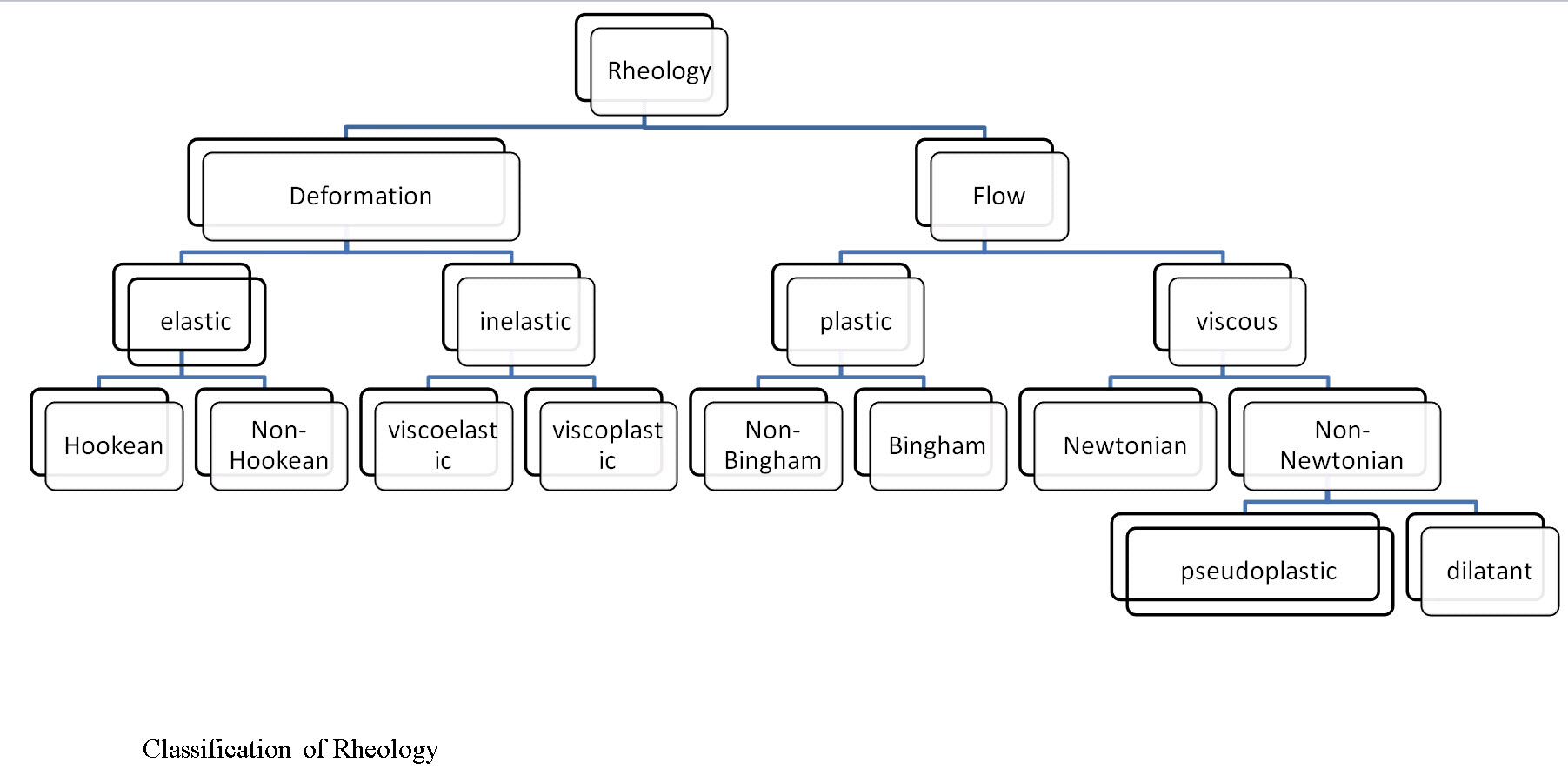

The classification of rheology is depicted in the fig

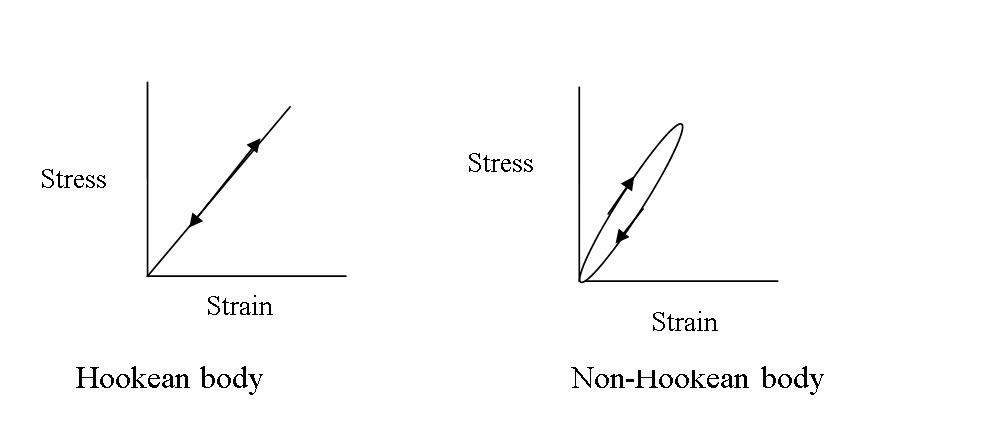

Hooke's law is a principle of physics that states that the force needed to extend or compress a spring by some distance is proportional to that distance.

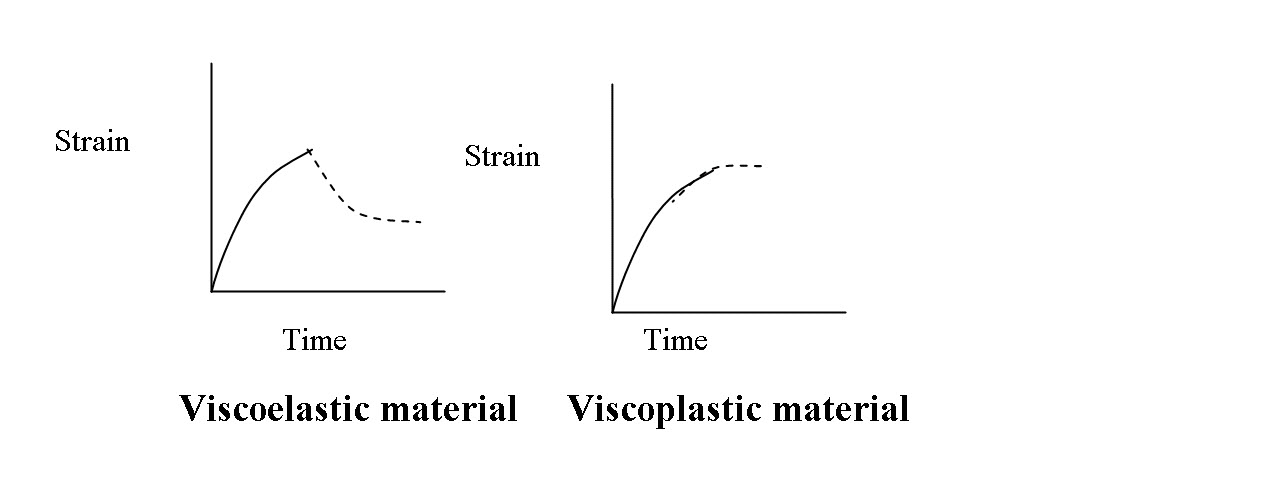

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like honey, resist shear flow and strain linearly with time when a stress is applied. Elastic materials strain when stretched and quickly return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time-dependent strain.

Viscosity and consistency

Viscosity/ dynamic viscosity/absolute viscosity: it is the internal friction of a liquid or its tendency to resist flow.

\[\mu=\frac{\sigma}{{\dot\gamma}}\]

\[\begin{array}{l}{\rm{=shear stress}}\\{\rm{=viscosity}}\end{array}\]

\[\dot\gamma=shearrate\]

The unit of viscosity is poise. One poise is defined as that viscosity in which a velocity gradient of 1 cm sec-1 is obtained when a force of 1 dyne is applied to two surfaces. It has the dimension of ML-1T-1

One centipoises (cP) is one of the commonly used unit, which is equal to 0.01 poise. Water at 20°C has a viscosity of 1.0 SI unit of dynamic viscosity is Pascal-second. 1 pascal-second is 10 Poise.

Fluidity: this is the reciprocal of viscosity

\[\varphi=\frac{{\dot \gamma }}{\sigma }\]

Kinematic viscosity: this is defined as the absolute viscosity divided by the density of fluid:

\[\vartheta=\frac{\mu }{\rho } = \frac{\sigma }{{ {\gamma \rho }\limits^ }}\]

\[\vartheta=inematicviscosity,stokes\]

m=viscosity in poise,

r= density, g cm-3

The dimension of kinematic viscosity is M2L-3

Apparent viscosity (ma): this is the viscosity of a non-Newtonian fluid expressed as though it were a Newtonian fluid.

Shear rate: this is the velocity gradient in a fluid as a result of an applied shear stress. It is expressed as reciprocal of seconds

Factors affecting Viscosity:

Temperature: a reciprocal relationship

Concentration of solids: direct non-linear relationship

Molecular weight of solute: direct non-linear relationship

Pressure: essentially constant over a pressure range of 0-100 atm and can be ignored for foods

Suspended matters: increases the viscosity

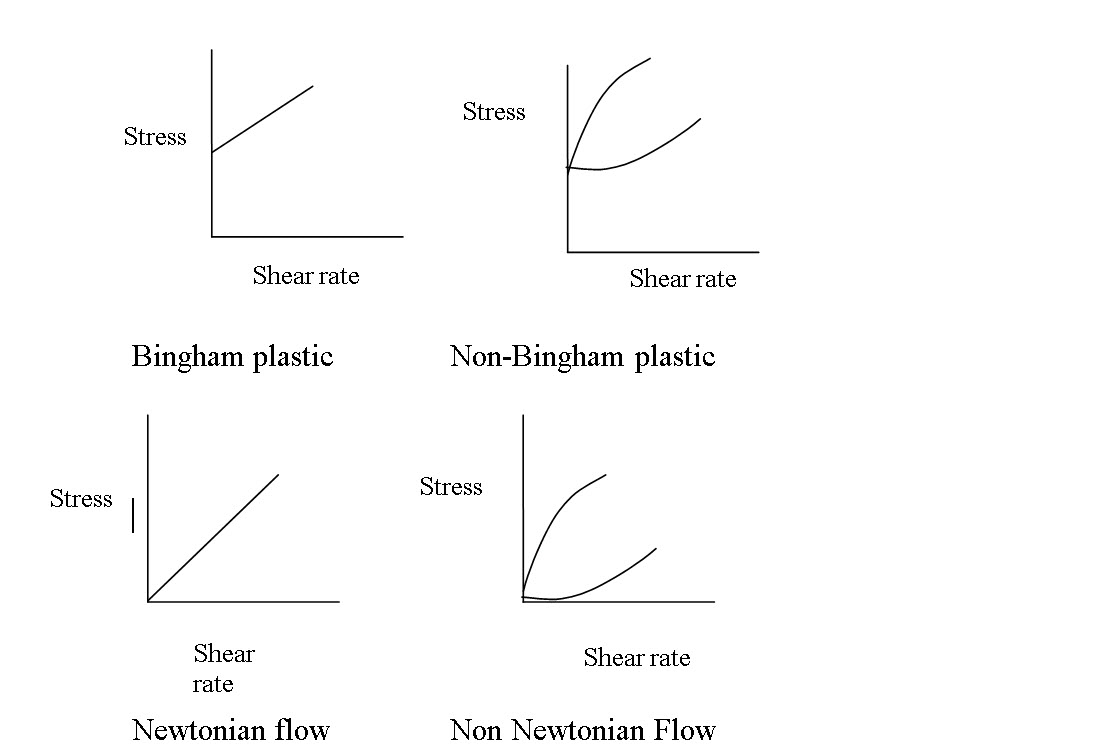

Types of viscous behavior:

Newtonian and non Newtonian fluid:

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like honey, resist shear flow and strain linearly with time when a stress is applied. Elastic materials strain when stretched and quickly return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time-dependent strain.

Newtonian fluid: Fluids are termed as Newtonian if the viscous stresses that arise from its flow, at every point, are proportional to the local strain rate i.e. the rate of change of its deformation over time. Eg. Water, carbonated beverages, sugar syrup, most honey, edible tea, filtered juice, milk

Non –Newtonian Fluid: A non-Newtonian fluid is a fluid whose flow properties differ in any way from those of Newtonian fluids or they are dependent on the shear rate or time and the viscosity is termed as consistency or apparent viscosity.

Most food materials exhibit non-Newtonian behavior.

Shear rate dependency:

Bingham plastic: a minimum shear stress known as ‘Yield stress” must be exceeded before flow begins. Eg: tomato ketchup, whipped egg white, whipped cream, mayonnaise, margarine

Pseudoplastic: In this type of flow an increasing shear force gives a more than proportional increase in shear rate, but the curve begins at origin. Eg. Salad dressing

Dilatant: the shear stress-shear rate plot of this type of a flow begins at the origin but is characterized by equal increments in shear stress giving less than equal increment in the shear rate.

Example: High solids, raw starch suspensions, chocolate syrups, 60% corn starch suspension is rare in finished foods

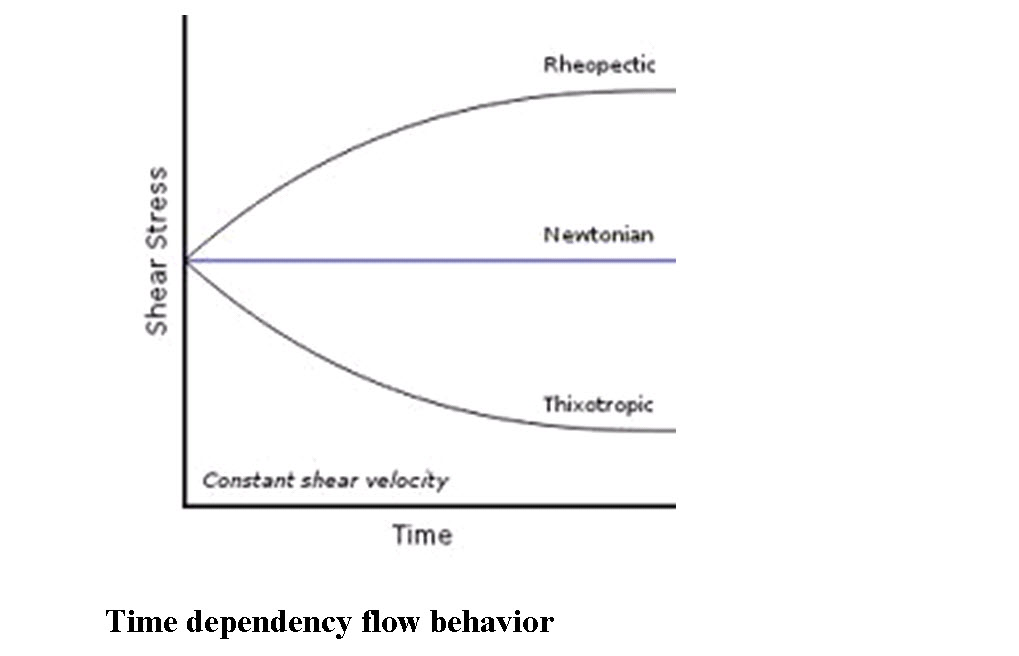

Time dependent behavior

Rheopectic: the apparent viscosity increases with time and the change is reversible; that is, the fluid will revert back to its original state on standing. Eg not found in food system

Shear thickening: the apparent viscosity increases with time and the change is irreversible; that is, the fluid stays in thick state when the shear stress is removed. Eg. Whipped egg white becomes stiff after beating

Thixotropy: the apparent viscosity decreases with time and the change is reversible; that is, the fluid will revert back to its original state on standing. Eg. Some starch gel

Shear thinning: the apparent viscosity decreases with time and the change is irreversible; that is, the fluid stays in thinner state when the shear stress is removed. Eg. starch pastes, gum solutions

References:

Bourne, M. C. 1982. Food Texture and Viscosity: concepts and measurement, Academic Press, USA

Mohsenin, N.N. 1986. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach Science Publishers: New York

Sahin S. & Sumnu, S. G. 2006. Physical Properties of Foods. Springer, USA