Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 21. Importance of Sensory Attributes

21.1 Introduction

Sensory evaluation can be defined as a scientific discipline used to evoke, measure, analyze and interpret results of those characteristics of foods and materials as they are perceived by the senses of sight, smell, taste, touch and hearing.

21.2 Importance

Physical, chemical, microbiological and sensory evaluations are the main procedures to examine foods for their quality attributes. For a product, sensory evaluation plays very important role for the following reasons:

What consumers like and why

Improve testing methodology

Ensures a cost-efficient new products

People can sometimes detect odorants at levels lower than what can be detected by an instrument.

Instruments can not measure liking

Monitor formulation changes.

Monitor processing changes.

Quality attributes can be measured quickly in quantifiable manner

A particular defect that cannot be detected by other analytical techniques can be evaluated by sensory evaluation

21.3 Applications

Inspection of Raw Materials: Quality of foods related to colour, appearance, aroma and taste can be quickly detected on the reception dock by the senses of smell, taste and sight.

New Product Development or Improvement of Existing Product: New products developed result into failure mainly because of poor sensory attributes and adoption of appropriate sensory methods during new product development helps to overcome such problems.

Cost Reduction: The use of low cost or alterative ingredients and simultaneously maintaining same sensory qualities will help in reducing cost of product .

Quality Control: Quality Control involves sensory evaluation at all stages of product. The changes in product quality in terms of colour, flavour and texture during processing and storage can be regularly monitored using sensory techniques.

Selection of Packaging Material: The newer types of packaging materials, particularly in forms of flexible films/pouches/laminates are being extensively used. The suitability of these films for packaging a food product can to be examined adopting sensory analysis along with some chemical/ instrumental method.

Shelf Life Studies: Food products during storage undergo many types of changes, for example, chemical, bacterial, enzymatic, physical, etc. All these alter the sensory properties, such as taste, colour, flavour, texture and appearance. Application of sensory evaluation monitors these changes and expiry date can be determined by using chemical and sensory techniques together.

Establishing Analytical/ Instrumental/ Sensory Relationships: Quick evaluation of the product quality can be established, for example, the titratable acidity of fresh milk ranges between 0.14 to 0.16%, and at 0.17% and above it may impart sour flavour. Relationship between sensory textural attributes, hardness, stickiness, chewiness, gumminess and elasticity/ sponginess with that measured by an instrument can also be established.

22.4 Relationship Senses with Sensory Attributes

The sensory attributes of any food are:

Appearance

Odor/aroma/fragrance

Consistency and texture

Flavor (aromatics, chemical feelings, taste)

However, in the process of perception, most or all of the attributes overlap and without training he or she will not be able to provide an independent evaluation of each. Flavor is the combined impression perceived via the chemical senses from a product in the mouth, i.e., it does not include appearance and texture. The term “aromatics” is used to indicate those volatile constituents that originate from food in the mouth and are perceived by the olfactory system via the posterior nares.

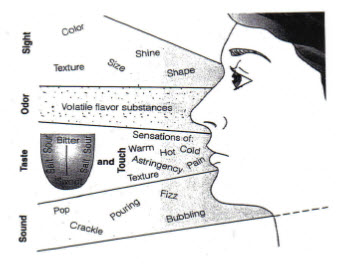

Fig: Role of five senses in sensory evaluation.

21.4.1 Appearance

The characteristics of a food product that can be evaluated by sense of sight are: style, neatness and cleanliness of package exterior, attractiveness of product finish, package closures, colour, consistency, body and texture and overall appearance. Colour and appearance aspects of products should not be overlooked because these features may render the product acceptable / unacceptable. The appearance is an attribute which a decision is taken to purchase or consume.

Color: A phenomenon that involves both physical and psychological components: the perception by the visual system of light of wavelengths 400 to 500 nm (blue), 500 to 600 nm (green and yellow), and 600 to 800 nm (red), commonly expressed in terms of the hue, value, and chroma of the Munsell color system. Deterioration of food is often accompanied by a color change.

Size and shape: Length, thickness, width, particle size, geometric shape (square, circular, etc.), distribution of pieces, e.g., of vegetables, pasta, prepared foods, etc.; size and shape are indications of quality of products.

Surface texture The dullness or shininess of a surface, the roughness, evenness; surface characteristics i.e wet, dry, soft, hard, crisp, tough are indicators of quality.

Clarity The haze or opacity of transparent liquids or solids, the presence or absence of particles of visible size are important indicators of quality.

21.4.2 Odour/ Aroma/ Fragrance

This sense plays paramount role in evaluation of quality of food products. The role of olfactory perception is greater in overall flavour than the taste. Food products are smelled for aroma perception immediately after the opening of closure/ package and earlier than the taste.

The odor of a product is detected when its volatiles enter the nasal passage and are perceived by the olfactory system. We talk of odor when the volatiles are sniffed through the nose (voluntarily or otherwise). Aroma is the odor of a food product, and fragrance is the odor of a perfume or cosmetic.

Aromatics, are the volatiles perceived by the olfactory system from a substance in the mouth. The amount of volatiles that escape from a product is affected by the temperature and by the nature of the compounds.

Volatility is also influenced by the condition of a surface: at a given temperature, more volatiles escape from a soft, porous, and humid surface than from a hard, smooth, and dry one.

Many odors are released only when an enzymatic reaction takes place at a freshly cut surface (e.g., the smell of an onion). Odorous molecules must be transmitted by a gas, which can be the atmosphere, water vapor, or an industrial gas, and the intensity of the perceived odor is determined by the proportion of such gas which comes into contact with the observer’s olfactory receptors .

21.4.3 Consistency and Texture

Tactual and mouth feel play an important role in examining the body and texture characteristics. The pressure between the teeth and jaws determine the hardness, chewiness and gumminess. The fingertips and ball of the thump help in determining other textural attributes, notably stickiness, elasticity/ sponginess and brittleness

The other set of attributes to be considered are those perceived by sensors in the mouth

Viscosity (for homogeneous Newtonian liquids)

Consistency (for non-Newtonian or heterogeneous liquids and semisolids)

Texture (for solids or semisolids)

Viscosity” refers to the rate of flow of liquids under some force, such as gravity. It can be accurately measured and varies from a low of approximately 1 cP (centipoise) for water or beer to 1000s of cP for jelly-like products.

Texture” is much more complex, can be defined as the sensory manifestation of the structure or inner makeup of products in terms of their reaction to stress, measured as mechanical properties (such as hardness/firmness, adhesiveness, cohesiveness, gumminess, springiness/resilience, viscosity) by the kinesthetic sense in the muscles of the hand, fingers, tongue, jaw, or lips.

Tactile feel properties, measured as geometrical particles (grainy, gritty, crystalline, flaky) or moisture properties (wetness, oiliness, moistness, dryness) by the tactile nerves in the surface of the skin of the hand, lips, or tongue.

21.4.4 Flavour

It is a companion sense with aroma in establishing the overall flavour of food products. In some of the products, particularly frozen foods where volatile compounds are not perceived by sense of smell at very low temperature, the sense of taste plays deciding role for evaluating the flavour.

Flavor, as an attribute of foods, beverages, and seasonings, has been defined as the sum of perceptions resulting from stimulation of the sense ends that are grouped together at the entrance of the alimentary and respiratory tracts:

The aromatics, i.e., olfactory perceptions caused by volatile substances released from a product in the mouth via the posterior nares.

The tastes, i.e., gustatory perceptions (salty, sweet, sour, bitter) caused by soluble substances in the mouth.

The chemical feeling factors, which stimulate nerve ends in the soft membranes of the buccal and nasal cavities (astringency, spice heat, cooling, bite, metallic flavor, umami taste).

21.4.4.1 Chemical / Trigeminal Factors

Chemical irritants such as ammonia, ginger, horseradish, onion, chili peppers, menthol, etc. stimulate the trigeminal nerve ends , causing perceptions of burn, heat, cold, pungency, etc. in the mucosa of the eyes, nose, and mouth.

Trigeminal effects assume practical significance: (a) when the olfactory or gustatory threshold is high, e.g., for short-chain compounds such as formic acid and (b) when the trigeminal threshold is low, e.g., for capsaicin.

The trigeminal response to mild irritants (such as carbonation, mouth burn caused by high concentrations of sucrose and salt in confections and snacks, the heat of peppers and other spices) may contribute to, rather than distract from, acceptance of a product.

21.4.4.2 Gustation

Like olfaction, gustation is a chemical sense. It involves the detection of stimuli dissolved in water, oil, or saliva by the taste buds which are located primarily on the surface of the tongue as well as in the mucosa of the palate and areas of the throat. Compared with olfaction, the contact between a solution and the taste epithelium on the tongue and walls of the mouth is more regular in that every receptor is immersed for at least some seconds.

The gustatory sensors are bathed in a complex solution, the saliva, which contains water, amino acids, proteins, sugars, organic acids, salts, etc. and they are fed and maintained by a second solution, the blood. Hence, we can only taste differences in the concentration of many substances, not absolute concentrations.

21.4.5 Noise

Vibrations in the local medium, usually air, cause the eardrum to vibrate. The vibrations are transmitted via the small bones in the middle ear to create hydraulic motion in the fluid of the inner ear, the cochlea, a spiral canal covered in hair cells which when agitated send neural impulses to the brain.

The noise produced during mastication of foods is a minor but not negligible sensory attribute. It is common to measure the pitch, loudness, and persistence of sounds produced by foods. The pitch and loudness of the sound contribute to the overall sensory impression. Differences in pitch of some rupturing foods (crispy, crunchy, brittle) provide sensory input, which we use in the assessment of freshness/staleness.

Common Noise Characteristics of Foods,

Pitch: frequency of sound, Crispy, Crunchy, Squeak

Loudness: intensity of sound

Persistence: endurance of sound over time, Perceived sounds (pitch, loudness, persistence) and auditory measurement

21.5. Other Properties

The Components of Texture

Hardness: force to attain a given deformation : Firmness(compression) Hardness (bite)

Cohesiveness: degree to which sample deforms (rather than ruptures)

Adhesiveness: force required to remove sample from a given surface Sticky (tooth/palate)

Denseness: compactness of cross-section Dense/heavy Airy/puffy/light

Springiness: rate of return to original shape after some deformation Springy/rubbery Cushy

Geometrical Properties: perception of particles (size, shape, orientation) measured by tactile means

Smoothness: absence of all particles

Gritty: small, hard particles

Grainy: small particles

Chalky/powdery: fine particles (film)

Fibrous: long, stringy particles (fuzzy fabric)

Lumpy/bumpy: large, even pieces or protrusions

Moisture Properties: perception of water, oil, fat, measured by tactile means

Moistness: amount of wetness/oiliness present, when not certain whether oil and/or water

Moisture release: amount of wetness/oiliness exuded/ Juicy

Oily: amount of liquid fat

Greasy: amount of solid fat

21.6 ISO Standards for Sensory Analysis

Note: There are also corresponding British Standards

ISO 3591-1977 Sensory analysis - Apparatus - Wine-tasting glass

ISO 3972-1991 Sensory analysis - Methodology - Method of investigating sensitivity of taste

ISO 4120-1983 Sensory analysis - Methodology - Triangular test

ISO 4121-1987 Sensory analysis - Methodology - Evaluation of food products by methods using scales

ISO 5492-1992 Sensory analysis — Vocabulary

ISO 5494-1978 Sensory analysis - Apparatus - Tasting glass for liquid products

ISO 5495-1983 Sensory analysis - Methodology - Paired comparison test

ISO 5496-1992 Sensory analysis - Methodology - Initiation and training

ISO 5497-1982 Sensory analysis - Methodology - Guidelines for the preparation of samples for which direct sensory analysis is not feasible

ISO 6564-1985 Sensory analysis - Methodology - Flavour profile methods

ISO 6658-1985 Sensory analysis - Methodology - General guidance

ISO 8586.1-1993 Sensory analysis - General guidance for the selection, training and monitoring of assessors - Part 1: Selected assessors

ISO 8586.2-1994 Sensory analysis - General guidance for the selection, training and monitoring of assessors - Part 2: Experts

ISO 8587-1988 Sensory analysis - Methodology — Ranking

ISO 8588-1987 Sensory analysis - Methodology - "A" - "not A"

ISO 8589-1988 Sensory analysis - General guidance for the design of test rooms

ISO 10399-1991 Sensory analysis - Methodology - Duo-trio test

ISO 11035-1994 Sensory analysis - Identification and selection of descriptors for establishing a sensory profile by a multidimensional approach

ISO 11036-1994 Sensory analysis - Methodology - Texture profile

ISO 11037-1999 Sensory analysis - General guidance and test method for assessment of the colour of foods

ISO 11056-1999 Sensory analysis - Methodology - Magnitude estimation method