Site pages

Current course

Participants

General

Module- 1 Engineering Properties of Biological Mat...

Module- 2 Physical Properties of Biomaterials

Module- 3 Engineering Properties

Module- 4 Rheological Properties of Biomaterials

Module- 5 Food Quality

Module- 6 Food Sampling

Module- 7 Sensory quality

Module 8. Quality Control and Management

Module 9. Food Laws

Module 10. Standards and regulations in food quali...

Lesson 32. Sanitation in food industry

Lesson 22. Controls for Test Room And Factors Effecting Sensory Evaluation

22.1 Introduction:

Sensory tests should be conducted in well integrated manner. Overall plan for effective evaluation is required with adequate facilities. A successful implementation of sensory evaluation program requires three major components:

Proper laboratory facilities

Sensory panels/evaluators, and panelist criteria

Rigorous training programme

22.2 Sensory Evaluation Laboratory

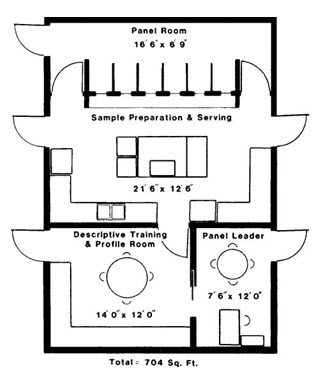

Many designs of the sensory evaluation laboratory are available. Generally sensory laboratory should include a briefing room, an office, testing booths and sample preparation room. The most important considerations for a sensory laboratory are location, ventilation, lighting, traffic pattern, sample preparation and presentation and experimental comfort.

22.2.1 Briefing Room: All the sensory evaluators are first assembled here. They are briefed by the organizer about the objective of the sensory work, scorecard and its use and give other instructions. This room should be adjoining to testing booths and have facilities for comfortable sittings.

22.2.2 Testing Booths/Area: This is the area where panel members carry out actual sensory evaluation of food products. Testing area should be located separately but in the immediate vicinity of the preparation area. This area is normally divided in to small booths (number of booths between 5 to 10) so that each panel member can independently evaluate the product.

22.2.2.1 Points to be considered:

The temperature and relative humidity shall be constant, controllable and comfortable for evaluators. A temperature of about 20oC and 62% relative humidity are considered to be optimum.

Noise level shall be kept to a minimum during the tests. The movement of persons shall also be restricted in the area.

The testing area shall keep free from odours. A slight positive pressure may be created in the testing area to reduce inflow of odorous air from other area.

Lighting particularly in testing booths shall be uniform, shadow free, controllable and of sufficient intensity to permit effective evaluation of the colour and appearance of samples. In most cases, 110 candle foot light is desirable. In order to mask differences in colour and other appearance characteristics special lighting devices, such as a dimmer device, colored lamps/filters or sodium vapour lamps, may be provided.

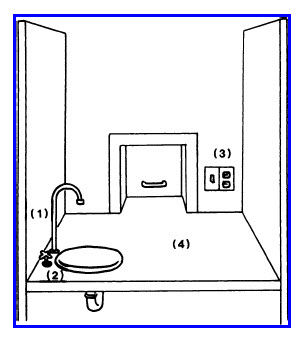

The size of each testing booth shall be sufficiently large to accommodate the samples, utensils, sink, rinsing agents and score sheet/card. An area of 0.9 m wide and 0.6 m deep is considered optimum for this purpose. The height of working space in the booth should be appropriate to allow comfort to the evaluator.

A counter on the serving/distribution area side shall be provided. Openings, covered by sliding doors, of convenient size may be provided for supplying samples into the booths from the serving counter. A system, such as light bulb on the counter side, is devised for evaluator to signal to the operator when he is ready for a sample.

22.2.3 Preparation Room: A laboratory for the preparation of samples shall be located adjacent to the testing area. Its location shall be such that the evaluators do not have to pass through testing area. The preparation area shall be well ventilated so that odours emanating from the samples preparation are removed. The type of equipment required in this area depends on the range of products, which will be processed here. The main components of the preparation room for food products are: working space, sink, cooking range, oven, refrigerator, deep freezer, blender, scoops, knives, balance, dishes, spoons, and cleaning and storage facilities. Utensils and cutlery used in sample preparation and presentation shall be of the materials, which do not impart any odour or taste to the product.

Figure: Sensory evaluation laboratory layout.

Fig: Sensory evaluation booth with hatch, tap water, small sink, easy access to clean table.

Limitations of sensory evaluation

1. The result may be highly variable

2. People with colds or other health problems temporarily lose their maximum effectiveness.

3. Emotional burdens may influence an individual's ability.

22.3 Sensory Panel

Trained panel members: The sensory qualities, particularly the flavour attributes are essentially to be measured subjectively. From early times this judging has been the preserve of experts who used to evaluate tea, coffee and wine. With the development of sensory evaluation techniques on scientific lines, the experts are being replaced by panels whose sensitivity and consistency have been established by training and repeated tests. The panel members analyse food products through properly planned experiments and their judgements are quantified by appropriate statistical analysis.

22.3.1 Selection of panel of judges: Actually one extremely discriminating pains taking and unbiased individual would suffice for tasting. Further one individual may not be able to discriminate different aspects of food quality. Hence a panel of judges may be used. Members of the panel should be carefully selected and trained to find out difference in specific quality characteristics between different stimuli and also direction and intensity of difference. The requirements for an ideal panel member are as follows.

He should be able to discriminate easily between samples and should be able to

distinguish appreciable differences in taste and smell.

He should have good health. If he is suffering from cold his sensitivity may be affected. A sick patient cannot judge the food correctly he should not be habituated to chewing pan

He should be experienced in the particular field.

He should have high personal integrity. He should not be prejudiced.

He should be able to evaluate objectively.

Willingness to spend time for the sensory evaluation work is required.

He should have interest in sensory analysis of samples and intellectual curiosity.

He should have ability to concentrate and derive proper conclusion.

He should be available and willing to submit to periodic test to get consistent results.

22.3.2. Different types of panels:

Trained panel: Laboratory panels must then be carefully trained for specific products or purposes. These tests aim at finding differences in specific quality characteristics between different stimuli and also direction and/ or intensity of the difference. Periodically the panel is given refresher training and tests. The number of members in the trained panel should be small varying from 5 to 10.

Discriminative, communicative or semi-trained panels: These panels are constituted of technical people and their families, who are normally familiar with the qualities of different types of food. They are capable, with few preliminary test runs, of following instructions for tests given, discriminating differences and communicating their reactions. Such panels of 25-30 are used to find the acceptability or preference of final experimental products prior to large scale consumer trials.

Consumer panels: Such panels are made up of untrained people chosen at random to represent a cross-section of the population for which the product is intended. The greater the number, the greater is the dependability of the result. A group of not less than 100 is considered the minimum.

22.4 Factors Influencing Sensory Verdicts

22.4.1 Physiological Factors

1. Adaptation

Adaptation is a decrease in or change in sensitivity to a given stimulus as a result of continued exposure to that stimulus or a similar one. In sensory testing this effect is an important unwanted source of variability.

2. Enhancement or Suppression

Enhancement — The effect of the presence of one substance increasing the perceived intensity of a second substance.

Synergy — The effect of the presence of one substance increasing the perceived combined intensity of two substances, such that the perceived intensity of the mixture is greater than the sum of the intensities of the components.

Suppression — The effect of the presence of one substance decreasing the perceived intensity of a mixture of two or more substances.

22.4.2 Psychological Factors

1.Expectation Error

Information given with the sample may trigger preconceived ideas. Panel usually find what they expect to find. A panelist who hears that a food product has been returned to the plant will have a tendency to detect aged flavors in the samples. Expectation errors can influence the validity of a test and must be avoided by keeping the source of samples a secret. Samples should be coded and the order of presentation should be random among the participants.

2.Habituation Error

This error results from a tendency to continue to give the same response when a series of slowly increasing or decreasing stimuli are presented, for example, in quality control from day to day. The panelist tends to repeat the same scores and hence to miss any developing trend or even accept an occasional defective sample. Habituation is common and must be counteracted by varying the types of product or presenting doctored samples.

3.Stimulus Error

This error is caused when irrelevant criteria, such as the style or color of the container, influence the observer. If the criteria suggest differences, the panelist will find them even when they do not exist. Samples served late in a test may be rated more flavorful because panelists know that the panel leader will present light-flavored samples first in order to minimize fatigue. To overcome such error avoid leaving irrelevant cues, schedule panel sessions regularly.

4.Logical Error

Logical errors occur when two or more characteristics of the samples are associated in the minds of the assessors. Knowledge that a darker beer tends to be more flavorful causes the observer to modify his verdict, thus disregarding his own perceptions. Logical errors must be minimized by keeping the samples uniform and by masking differences with the aid of colored glasses, colored lights, etc. With trained panelists the leader may attempt to break the logical association by occasionally doctoring a sample with quinine in order to produce high bitterness combined with low hop aroma.

5.Lack of Motivation

It is the responsibility of the panel leader to create an atmosphere in which assessors feel comfortable and do a good job. An interested panelist is always more efficient. Panelists should be made to feel that the panels are an important activity.

6. Impulsiveness Vs. Timidity

Some people tend to use the extremes of any scale, thereby exerting more than their share of influence over the panel’s results. Others tend to stick to the central part of the scale and to minimize differences between samples. In order to obtain reproducible, meaningful results, the panel leader should monitor panelists scores on a daily basis, giving guidance in the form of typical samples already evaluated by the panel and, if necessary, using doctored samples.

7. Poor Physical Condition

Panelists should be excused from sessions:

if they suffer from fever or the common cold, in the case of tasters, and if they suffer from skin or nervous system disorders in the case of a tactile panel;

if they suffer from poor dental hygiene or gingivitis;

in the case of emotional upset or heavy pressure of work which prevents them from concentrating.

Smokers can be good tasters but should refrain from smoking for 30 to 60 min before a panel.

Strong coffee paralyzes the palate for up to an hour.

Tasting should not take place the first 2 h after a major meal. The optimal time for panel work (for persons on the day shift) is between 10 a.m. and lunch. Generally the best time for an individual panelist depends on his biorhythm: it is that time of the day when one is most awake and one’s mental powers are at their peak.

22.5 Factors affecting Sensory Evaluation

i) Health of Evaluator: The evaluator should be physically and mentally in good health. The sensitivity for evaluator in respect of sense of smell and taste should be normal. He/she should not be suffering from anosmia and ageusia.

ii) Age: Evaluators should preferably be in the age group of 18-50 years. Persons of younger age are unable to properly interpret and communicate the sensory results, whereas at older age the memory decreases. Sharp memory of evaluator is considered highly useful in judging of food products, particularly for quality control applications.

iii) Interest and Motivation: Sensory evaluation work is very time consuming and sometimes fatigue also. The evaluator should, therefore, have interest and be motivated.

iv) Adaptation: Continuous exposure of evaluator to a particular stimulus, particularly at high concentration for long time, leads to decrease in his sensitivity (also called as fatigue). It is therefore desirable either to give sufficient time between the samples or use taste sanitizers, such as brine solutions, fruits and mild acids. The taste sanitizers improve the taste sensitivity or bring it back to normal level.

v) Sampling: The sample should be representative of the lot. Care shall be taken that no loss of flavour occurs and no foreign tastes or odours are imparted during the sample presentation. The sample should be drawn from a bulk lot in such a way that body and texture characteristics are not changed.

vi) Sample Numbers and Quantity: For economic efficiency of sensory testing, larger the number of samples per session, the better it will be. Normally 5-8 samples with average intensity of flavour for each sitting are optimum. The amount of each sample should be about 25-50 ml or gm, which is sufficient for one full sip or bite.

vii) Score Card: The evaluation card should be simple, brief, easy to follow and all important sensory attributes included in it. It should be clearly printed and the matter should be arranged in logical sequence. Terminology used shall be clear and understandable.

viii) Miscellaneous Factors: The temperature of serving should be close to that recommended for each product . The test should be carried out preferably one hour before or after lunch. Use of materials, which are likely to vitiate results, such as smoking, chewing pan and taking intoxicants by the evaluator should have a time lapse of at least 30 minutes before the test.