Site pages

Current course

Participants

General

Module 1. Dairy Development in India

Module 2. Engineering, thermal and chemical proper...

Module 3. Unit operation of various dairy and food...

Module 4. Working principles of equipment for rece...

Module 5. Dairy plant design and layout, compositi...

Module 6. Deterioration in products and their cont...

Module 7. Physical, chemical and biological method...

Module 8. Changes undergone by the food components...

Module 9. Plant utilities requirement.

References

Lesson 13. Working principles of equipment for sterilization of milk

13. Introduction

We know milk is a highly perishable commodity. Its myriad nutrients makes it extremely favourable medium for the growth of microorganisms. It is, therefore, essential that milk is subjected to certain processing treatments for enhancing its keeping quality and ensuring safety to consumers.

Thermal processing is the most prevalent preservation process employed in the dairy and food industry. Starting from pasteurization, which is a mild heat processing technology, in-bottle/in-package sterilization emerged as a means of extending shelf life of milk for several weeks at room temperature. Considerable changes in nutritional and sensory quality due to severity of heat treatment in this process restrict its application to only special milks. Ultra-high-temperature processing, a relatively new processing know-how, became popular as it uses very high temperature (140oC) for short time (2 sec) to sterilize milk. Such a time-temperature combination ensures minimal change in the product quality. Sterilized milk is then packaged in sterile container under aseptic conditions to prevent post-processing contamination. The product thus obtained has very long storage life.

13.1 Sterilization

13.1.1 Definition

Sterilized milk refers to a product obtained by heating milk in a container in a commercial cooker/ retort to temperatures of 110-130oC for 10-30 min. The process is also referred as in-container sterilization. Sterilized milk is generally intended for prolonged storage at room temperature (up to 6 months). The major objective of heat sterilization is to destroy microbial and enzymatic activity. The length of time and magnitude of temperature employed during processing depend on the type of the product, number and heat resistance of microorganisms and enzymes present in milk. The heat resistance of microorganisms or enzymes is generally evaluated in terms of D-value or Z-value. Sterilization load or heat load for sterilization is generally expressed in terms of F0 value.

13.1.2 Theoretical Basis

Clostridium botulinum is considered as the index organism for assessing thermal sterility in foods. Under anaerobic conditions, inside a sealed container, it can produce botulin, a toxin, which can be 65% fatal to humans. Therefore, destruction of this organism is a minimum requirement of heat sterilization. As milk is a low acid (pH>4.5) food, it is recommended to achieve 12 decimal reductions for C. botulinum. This can be achieved by heating the product at 121oC for 3 min (F0 = 3). However, this minimum treatment may produce milk that is safe but not necessarily commercially sterile. This is so because there are more heat-resistant spores present in milk. There is B. stearothermophilus or B. sporothermodurans. These spores are not pathogenic. Their presence may require heat treatment equivalent to two (2) or more decimal reductions. This may correspond to an F0 value of 8. Target spoilage rates should be less than one survivor in every 10,000 containers.

13.1.3 Types of Sterilization Plants

Sterilizing retorts are either batch type or continuous in operation. Batch type sterilizers may be either vertical or horizontal. Horizontal retorts are easier to load or unload. They have facilities for agitating containers/cages. However, they require more floor space. Typically such horizontal retorts contain concentric cages. Cans are loaded horizontally into the annular space between the cages. When cages are full, the retort is sealed. The cages are supported by guide rails, which slowly rotate them. This stirring of the contents in cans facilitate proper heating. Continuous retorts are generally equipped with better controls. They cause very gradual change in pressure inside the cans. Thus products are heated more uniformly. Can seams are also subjected to less strain in comparison to batch process.

13.1.4 Continuous sterilizers:

They are mainly of three types: (a) cooker-coolers; (b) hydrostatic sterilizers; and (c) rotary sterilizers. Cooker-coolers carry cans on a conveyor which passes through three sections of a tunnel. These sections are maintained at different pressures for preheating, sterilization and cooling. The hydrostatic sterilizer consists of a chamber equipped with provision for steam injection. The chamber that is partially full of water is connected to two water columns (12 to 18 meter tall, barometric leg) which are used to adjust pressure in the chamber. If the height of the water columns is changed, the steam pressure is changed and therefore the maximum attainable temperature changes. For example, to get a temperature of 116oC, a difference in height between the two water columns should be 10.7 m while for attaining 121oC temperature in the chamber, the water column difference should be 13.7 m. A conveyor with provision to accommodate cans of different sizes moves through the steam chamber carrying the food cans. The heating time could be regulated by varying the speed of the conveyor. Hydrostatic sterilizers are very flexible and suitable for large capacity plants. However, size of the structure and high capital costs are the major disadvantages of this system.

Continuous rotary sterilizer consists of several horizontal inter linked cylinders which allow for preheating, heating, precooling and cooling in upto four continuous stages. The vessel has a spiral track on the inner wall. A spoke or reel within the centre of the cooker causes the cans to roll along the spiral track. Rotary valves used to interconnect the shells, maintain pressure in the heating and cooling sections. Sealed cans are introduced directly from the sealing machines. The contents inside the cans are mixed as cans travel along the helix and therefore enhance heat transfer and ensure less heat damage to the product. Cans coming out of the cooker are directly taken to labelling and palletizing machine. Rotary sterilizers are particularly suitable for processing of milk and milk based products, which are extremely heat sensitive and susceptible to browning.

13.1.5 Description of the Canning Process

Basic operations in conventional retorting/canning process include: preparation of the raw material, filling of the container, exhausting, sealing of container, sterilization, cooling of the cans, labelling and storage. The preparation of raw materials refers to washing, peeling, cutting, blanching, precooking, etc. in case of fruits, vegetables, meat, etc; and preheating, mixing, homogenization, etc; in case of milk. Filling of containers can be carried out either manually or mechanically. Correct and accurate filling is important from economic standpoint as well as for prevention of entrapment of large volume of air/ gas inside the can, which might decrease the intensity of heat treatment. Exhausting is an essential operation in the canning process and involves removal of air/ oxygen from the container before it is closed. Removal of air ensures minimum of strain on the can seams or pouch seals through expansion of air during heat processing. Removal of oxygen is essential to prevent internal corrosion of the container through oxidation and creation of vacuum inside the container while cooling. Absence of oxygen inside the container also delays oxidative deterioration of the product besides destruction of ascorbic acid. After exhaustion, containers are sealed. Depending on the type of containers (metal cans, glass bottles, flexible pouches); sealing machines are chosen. Glass jars are normally vacuum-sealed while tins are closed with a double sealing on the seal side and may also be vacuum-sealed. Flexible retortable pouches are sealed by fusion of two thermoplastic materials through application of heat by heated plates or jaws. Product in the closed containers is heated in the sterilizer in an atmosphere of saturated steam or hot water or air-steam mixture. The sterilizing action of steam depends on its latent heat of vaporization as it condenses on the surface of the can.

Saturated steam condenses readily and is therefore an efficient sterilizing medium. Displacement of all air present in the retort by steam before the sterilizer is brought to operating temperature is a very essential step. This is also known as venting. The purpose of this processing step is to maintain uniform steam-air mixture in the sterilizer and prevent under processing. Sterilization temperature – time combination in retorts may vary from 110 – 130oC for 10-30 min. Sterilized containers are then cooled and brought to room temperature for labelling and storage. Turbidity test developed by Aschaffenburg is conducted to ensure sterility of the product. This is an indirect test and it measures denatured whey proteins. Complete denaturation indicates that the milk is adequately sterilized.

13.2 UHT (Ultra High Temperature) Processing

13.2.1 Definition

UHT milk can be defined as a product obtained by heating milk in a continuous flow to a temperature in excess of 125ºC for not less than two seconds and immediately packaging in sterile packages under aseptic conditions. In India, UHT milk is generally processed at 140oC for 2 seconds.

13.2.2 Theoretical Basis

Heating of milk results in death of microorganisms. While some bacteria are destroyed by pasteurization (71.7oC/15 sec) only, some survive this thermal treatment. Bacillus subtilis and Bacillus stearothermophillus spores are very heat resistant. Of the two, Bacillus stearothermophillus spores are most heat resistant. It is therefore, considered index organism for evaluating performance of UHT processing. Heating of milk at higher temperatures also result in undesirable changes in chemical quality. Browning reactions are particularly important. Higher thermal load results in more browning and therefore loss of flavour and quality. In the temperature range of 100-120oC, time required for death of almost all B. stearothermophillus spores are more. This may therefore result in more browning in the product.

However, if milk is treated in the UHT range i.e. 135-150oC for only few seconds, almost all spores may get killed and browning would be minimum. Loss of nutrients and total quality also will be minimum. A product processed in this temperature range will be thus microbiologically safe and yet superior in terms of overall quality.

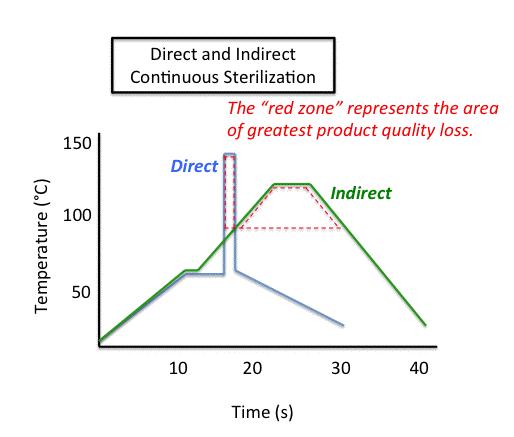

13.2.3 Types of Sterilization Plants

There are two types of UHT plants: Direct type and Indirect type. In direct type plants, heating is done by mixing product and steam. In indirect type plant, product is heated by steam or hot water without the two coming in direct contact. Heating in direct type plant is very rapid particularly between 80-140oC and total heat load is less. Changes in the product quality are therefore minimum. In indirect plant, rise in temperature is very gradual. Therefore, heat load on the product is more. Changes in chemical quality are comparatively more in indirect type than in direct type plants.

13.2.3.1 Direct Heating Plant:

There are two types of direct heating plants (a) Injection type and (b) Infusion type.

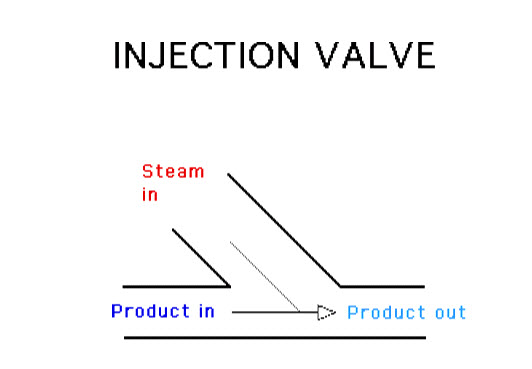

13.2.3.1.1 Injection type:

Processing is through steam-into-milk arrangement. Steam injector is the heart of this plant. Preheated milk at 80-90oC enters the injector nozzles from one side. Steam at slightly higher pressure enters the injector from the other side. As the steam mixes with milk, steam condenses and the product is rapidly heated. Rapid condensation of steam prevents entry of air in holding tube. Air in holding tubes results in improper heating. Backpressure is maintained on the discharge side. Backpressure ensures that product does not boil in holding tube. Boiling may result in fouling and improper heating of milk. Several designs of injector are available.

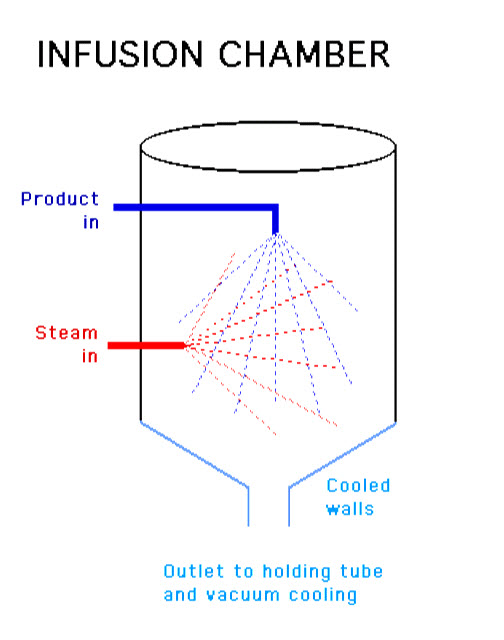

13.2.3.1.2 Infusion type:

In this system, milk is heated by milk-into-steam arrangement. The processing unit consists of a chamber filled with pressurized steam. Milk enters the chamber from the top. There are two alternative arrangements for distribution of milk. In the first type, milk flows to a hemispherical bowl with loose circular disc closing the top. When the bowl is full, milk overflows and falls in droplets through the steam environment. In an alternative arrangement, milk flows through a series of parallel and horizontal distribution tubes. These tubes have slits along the bottom and milk flows like a thin film through the chamber. As milk reaches the bottom of the chamber, it is heated to desired temperature. This system is particularly suitable for thicker liquids and for liquids suspended with smaller chunks.

13.2.3.2 Advantages and Disadvantages of Direct Heating System:

During processing in direct type heating systems condensing of steam coming into product contact results in dilution of the product. To remove this excess of water from the product, cooling is done in an expansion cooling vessel. In expansion vessel, along with the evaporating water incondensable gases and undesirable flavour volatiles produced during heating are also removed. The product therefore tastes better. Steam injection induces formation of casein aggregates, which give “chalky” or “astringent” mouthfeel to the product. Aseptic homogenizer, which can safely homogenize the product after final heating section, is generally preferred with direct heating systems to overcome such defects in the product. Rate of heating is very high (takes less than 1 sec to attain sterilization temperature).

Thick/viscous liquid can also be easily processed. Deposit formation is minimum, hence plant can be operated for longer time without cleaning. Undesirable flavours are removed during flash cooling. Oxygen is removed during cooling, hence oxidized flavour defects are delayed during storage. Cost of processing per unit volume of milk is high. Requires additional equipment (vacuum expansion chamber and aseptic homogenizer) – cost of plant is twice that of indirect type plant. Heat energy requirement is very high. Water and electricity (25-50% more than indirect type) consumption are high. Requires culinary steam and hence special boiler. Creates greater noise during operation.

13.2.3.3 Indirect Type Heating System:

There are three types of indirect heating systems: (a) Plate heat exchangers (b) Tubular heat exchanger (c) Scraped surface heat exchanger.

13.2.3.3.1 Plate heat exchanger:

This resembles plate heat exchanger of HTST plants. Several rectangular stainless steel plates with corrugations are arranged in sequence. These plates are then mechanically tightened to hold together. Corrugations on the plates induce turbulence and therefore result in high heat transfer. High temperature processing generates high internal pressure. The gaskets are therefore made of heat resistant materials such as medium nitrile rubber or resin cured butyl rubber. A major advantage of this plant is therefore simple design and comparatively less cost. If deposit formation is more, plates can be removed and manually cleaned.

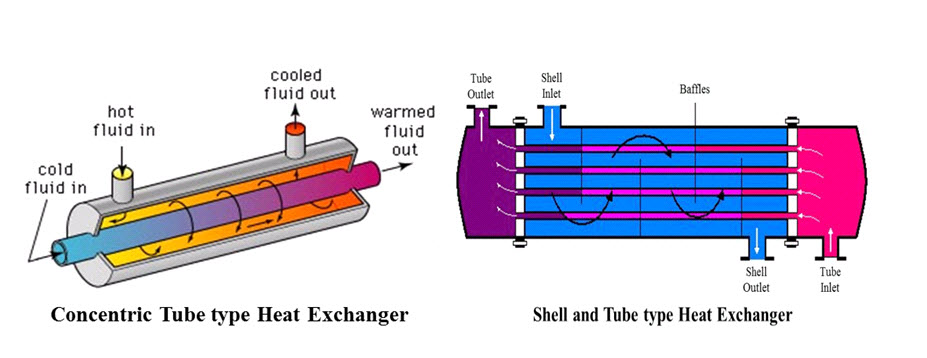

13.2.3.3.2 Tubular heat exchanger:

There are two types of tubular heat exchangers – (a) concentric tube, (b) shell and tube type. Concentric tube type heat exchangers comprise two or three stainless steel tube lengths put one inside another. Spacer is placed in each inner tube space to maintain them concentric. Several such multiple tubes are bound together and placed into an outer cylindrical housing. Two tube heat exchangers are used for simple cooling and heating. In triple tube heat exchanger, available heat transfer area is doubled. It is generally used in final cooling section. It is also suitable for processing of thick liquids, which generally reduces heat transfer rate. Product flows through the middle annular space. Heating or cooling medium passes through inner tube and outer annular space. In shell and tube type heat exchangers, 5-7 straight lengths of smaller tubes (10-15 mm internal diameter) are assembled in an outer tube. The smaller tubes are connected to large outer tube at both ends by a manifold. Product passes through the smaller tubes.

Heating or cooling medium passes through the space around them in a counter current flow. Tubular heat exchangers are mechanically very strong and can withstand even very high internal pressure generated during homogenization (200- 300 bar). Therefore the need for acquiring an aseptic homogenizer to be placed after heating section is totally eliminated. Instead, the high pressure reciprocating pump of an ordinary homogenizer can be placed before the sterile section. The homogenizing valve can be put at any point on the downstream side (even after final heating section). The problem of product contamination arises from the homogenization pump and not the valve. Therefore, with tubular heat exchangers, the product can be homogenized before sterilization, after sterilization or on both the occasions. Fat rich products like cream require homogenization after final heating to prevent re-association of fat globules due to high temperature processing after homogenization.

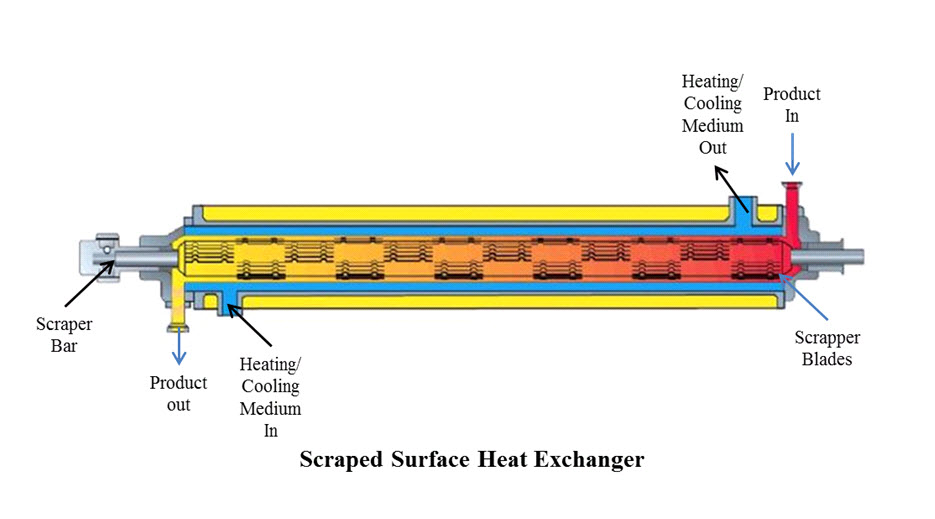

13.2.3.3.3 Scraped Surface Heat Exchanger (SSHE):

It is a very specialized type of heat exchanger. It consists of a jacketed cylinder. A shaft passes along the axis of the cylinder. The shaft is supported by bearings at both ends of the cylinder. The shaft also carries several scrapper blades. As shaft rotates, scrapper blades provide turbulence and physically remove the product from the surface of the wall. The colder product subsequently replaces the heated product and the cycle continues.

SSHE is used only for heating very thick liquids. SSHE units are very expensive and have poor energy conversion efficiency. The cost of processing is therefore very high.

13.2.3.4 Advantages and Disadvantages of Indirect Heating System:

It is simple in design and requires less pumps and controls. It can regenerate 90% of the thermal energy requirement. It does not require aseptic homogenizer, which is very costly. It does not require culinary steam and therefore special type of boiler. The indirect type plant is less noisy. It requires low initial capital and operational cost is also comparatively less. In indirect type heat exchanger, rate of heat transfer is low. More heat load results in less acceptable product quality. Deposit formation is more and therefore plant requires frequent cleaning. For removal of dissolved oxygen from milk, additional equipment ‘deaerator’ is required.

13.2.4 Aseptic Packaging

Aseptic packaging can be defined as the process in which UHT processed or sterilized milk is filled in pre-sterilized containers under aseptic/sterile environment. This ensures that there is no post processing contamination of the milk so that the product has longer shelf life. Since aseptic packaging systems are complex, great care is needed to prevent contamination. Before the start of product packaging, trial runs are routinely conducted with sterile water. Critical parts of the filling machine and carton forming systems are thoroughly checked. The seal integrity of the package and overall microbial quality of the packaging material are monitored properly. Generally, for a good processing plant permissible spoilage rate is one in every 5000 sterilized, filled and sealed package of one litre carton.

13.2.4.1 Types of Sterilizing Medium

Sterilizing mediums to be used in aseptic packaging systems could be broadly classified under two categories: physical sterilization mediums and chemical sterilization mediums.

- Physical sterilization mediums:

Dry heat/ superheated steam (300oC)

Ultraviolet radiation (UV rays, 250 nm wavelength)

Ionizing radiations (gamma rays, 2.5 M rad intensity)

- Chemical Sterilization Mediums

Ethylene oxide

Hydrogen Peroxide (H2O2)

13.2.4.2 Type of Packaging Materials

Metal container:

Cans made of tin plate or drawn aluminium are generally used for packaging of condensed milk, viscous liquids and chunk-in-gravy type of products. These are expensive and unsuitable for low cost products like liquid milk.

Laminates/cartons:

Different layers of flexible films of different materials viz. paper, polyethylene and aluminum foil are co-extruded to form a laminate. These materials have specific properties viz. water vapour transmission, burst strength, etc; and hence when co-extruded form an ideal packaging film.

Plastic films:

Black and transparent polyethylene films are co-extruded for packaging of UHT processed milk intended for 2-3 weeks shelf life.