Site pages

Current course

Participants

General

Module 1. Dairy Development in India

Module 2. Engineering, thermal and chemical proper...

Module 3. Unit operation of various dairy and food...

Module 4. Working principles of equipment for rece...

Module 5. Dairy plant design and layout, compositi...

Module 6. Deterioration in products and their cont...

Module 7. Physical, chemical and biological method...

Module 8. Changes undergone by the food components...

Module 9. Plant utilities requirement.

References

Lesson 14. Working Principles of Butter Manufacturing

14. Introduction

Butter is essentially the fat of the milk. It is usually made from sweet cream and is salted. However, traditionally it is being made from cream that had been allowed to stand and sour naturally. The cream is then skimmed from the top of the milk and poured into a wooden tub. Butter making is done by hand in butter churns. The natural souring process is, however, a very sensitive one and infection by foreign micro-organisms often spoiled the result.

Today's commercial butter making is a product of the knowledge and experience gained over the years in such matters as hygiene, bacterial acidifying and heat treatment, as well as the rapid technical development that has led to the advanced machinery now used.

The principal constituents of a salted butter are fat (80 - 82%), water (15.6 - 17.6%), salt (about 2-3%) and residual curd (about 1.5 %). In butter making the oil-in-water emulsion of cream is converted by the process of churning into the water-in-oil emulsion of butter. The consistency should be smooth so that the butter is easy to spread and melts readily on the tongue.

14.1 Important Steps in Butter Making

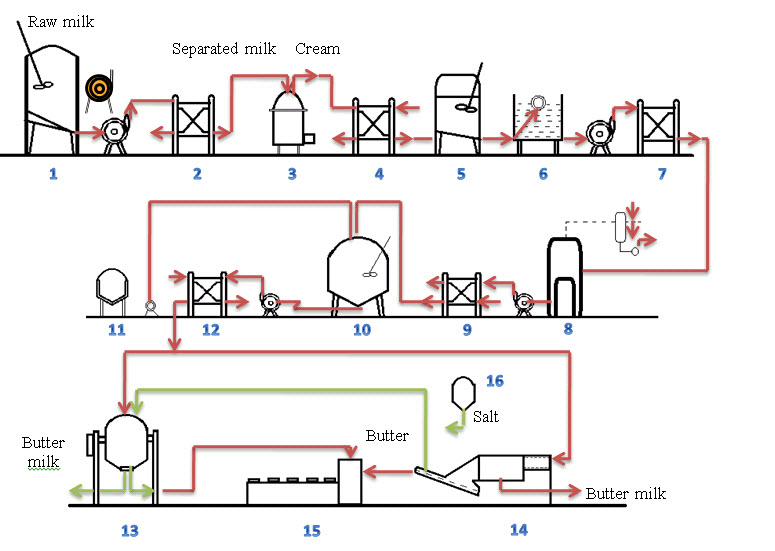

Figure 14.1 presents a flow diagram of butter making starting with the raw milk delivered to the plant.

The severe heat treatments to cream should be avoided to retard the migration of copper from the milk serum into milk fat and ultimately to control development of rancid flavour and to increase the shelf-life of butter.

The plate heat exchanger design should avoid high pressure differentials, as the high shear rate associated with this could result in premature damage to the milk fat globules. This damaged cream would be unstable and liable to cause problems on subsequent handling prior to butter making. Cream may also be damaged by incorrect sizing of pumps, particularly centrifugal pumps. It is recommended that the cream for butter making be handled by positive displacement pumps. Care is needed to avoid excessive shear forces which would create too many small fat globules. This would result in higher losses of fat in the buttermilk. Any rubber components in the plant for cream handling or butter making must be of a fat resistant type, e.g. nitrile rubber. Rubber compounds, that are not fat resistant, break down after several days of contact, and will contaminate the product.

1. milk storage tank 2. preheater 3. separator 4. cream cooler 5. cream storage tank 6. balance tank 7, heater 8. de-gassing 9. cooler 10. cream ripening tank 11. starter culture 12. heat exchanger 13. butter churn (batch process) 14. continuous butter making machine 15. butter packing 16. salt container

Fig.14.1 Flow diagram of butter manufacture

14.1.1 Churning

The purpose of churning is to destroy the 5 to 10 nm thick fat globule membrane in which the butter fat exists partly as a liquid. Liquid fat should leave the fat globules and coalesce to form fat agglomerates or butter granules. For agglomeration of fat globules into butter granules to take place, it is necessary that part of the fat be in crystalline form. The rapid motion of the fat globules in relation to each other, aided by collisions with surfaces and by high turbulence causes the fat crystals to penetrate the membranes as these become progressively thinner. Free fat finally emerges from the porous parts of the membrane and fat agglomeration takes place.

Agglomeration is difficult at too low temperature when the proportion of liquid fat is too low and equally difficult at too high a temperature when all the fat is in liquid form.

14.2 Batch Butter Churns:

14.2.1 Rotating churns

The rotating butter churn was introduced in the nineteenth century and gradually from farm butter making it was adopted for the factory butter making by the butter industry. The rotating churns consisted mainly of a barrel rotated on an axis with shelves of various kinds to increase the agitation effect. The first combined churn and butter worker was introduced in USA in 1890. The combined churn and butter worker was of short barrel type.

14.2.2 Batch method using rotating churns

The use of batch churn for butter manufacture is on decreasing trend because of increase in popularity of improved designs of continuous butter making machines. In India, however, the butter produced by organized dairies is made by batch churns, except a few leading dairies.

The capacity of batch churns varies from 100 to 3000 kg of cream per batch. The shape is mostly cylindrical with front opening , cone with cylinder, single cones and double cone etc. The churn is short in length and large in diameter. Baffles are fitted internally to improve agitation. In some designs, ribbed rollers are fitted through which butter grains pass. The fittings like air vent, sight glass, butter milk outlet, opening for cream inlet, and outlet for butter are mounted on barrel. Butter does not adhere on the wood, while the metal churns, the inside surface is roughened (sand or lead shot blasting) to allow film of moisture on the surface between the metal and the butter.

The degree of mixing depends on the amount of cream in the churn and on the rate of revolution. Too low a rate will not give sufficient turbulence and with too high a speed there is the danger that the centrifugal force (m ω2R) will exceed the gravitational force (mg) and that the cream will stick to the periphery and rotate there with drum. The best condition for churning i.e. maximum turbulence, are achieved when the force of gravity just exceeds the centrifugal force.

i.e.: mω2R < mg

(2пn)2 R < g

Or

n < [g/R]1/2 . 1/2п ≈ 1/(2√R)

The energy consumption is about 7 - 11 kWh per 1000 kg of butter of which about 90% is used in churning and 10% in working. The lower values are for the cream with a higher fat content.

i) Loading the cream

Pasteurized cream with 35 - 40 percent fat, properly aged is pumped into the churn. Cream is filled to 40 - 45% of the volume of the churn. The cream may be ripened.

ii) Churning

The churn can be operated at different speeds. The range of speed depends on the size and shape of the churn. The cream is churned at the churning speed (60 - 100 rpm). The cream is well whipped by the corners, edges and other irregularities in the churn. Chilled water is sprayed over the churn during churning operation. It takes about 35 – 40 minutes for the formation of butter granules of peanut size.

iii) Buttermilk draining

The churn is stopped and buttermilk is drained off. Equal quantity of pasteurized wash water is added.

iv) Washing

The churn is started again. The wash water is drained off after some time. Two or three washings are generally given.

v) Working

The wash water is drained off and salt is added. The churn is then operated at lower speed (25 - 50 rpm) for working as compared to that at churning. After 3 – 5 min., sample is taken and moisture is adjusted by adding required quantity of water. The working is carried out till desired body and texture is attained. Applying vacuum of 5 m of water gauge during working gives close texture by reducing the content of air.

vi) Unloading and packing

The butter is unloaded in trolleys and then packed for sale. Different types of packing machines are employed for the required size of packages.

Care of churns:

a) Driving gear should be filled with lubricating oil and every alternate year replace it.

b) Never change the speed while the churn is running.

c) Solid foundation is necessary for churn and driving gear

d) Gaskets to be maintained leak proof.

e) Proper roughness inside of the churn should be maintained.

f) Proper cleaning of the churn after the operation is over.

Fig. 14.2.a types of batch butter churns

Fig. 14.2.b Types of Batch Butter Churns

14.3 Continuous Churns

Continuous butter making was first introduced in 1889 following successful development of centrifugal separation of cream from milk by a continuous process. The machine developed was first exhibited in England in 1889. The machine was known as butter extractor. The separated cream was beaten with great violence and thus converted into butter granules, which was discharged along with the buttermilk.

14.3.1 Continuous butter making

Different continuous butter making machines which are used in dairy industry can be classified into three categories according to the churning principle involved as under:-

- Machines operating on Fritz process or floatation churning, where accelerated churning and working takes place. Few examples of this type are known as Westfalia Separator (West Germany), Contimab (France), HMT (India) and Masek (Czechoslovakia).

- Machines operating on concentration of normal cream followed by phase inversion, cooling and mechanical treatment. Machines with commercial names as Alfa (West Germany) and Alfa-Laval (Sweden) fall under this category.

- Machines operating on concentration of normal cream de-emulsification and re-emulsification into butter are available with commercial names of Gold’n Flow Process (USA), New Way Process (Australia) and Creamery Package Process (USA).

The important steps in butter making by these three processes are outlined below. One representative machine from each of the three processes is described briefly here.

14.3.2 The Fritz Process

The first prototype of modern machine developed by Fritz was demonstrated in the year 1940. Only this process has managed to consolidate its place in the Western Europe and countries like India. This is probably because its close similarity with ordinary batch method and the ease with which it can be applied practically. It contains three main parts, viz. Churning cylinder, draining and washing cylinder and worker. Capacity is up to 10000 kg/h.

i) Preparation of cream

For smooth operation of the churn, the cream must be of uniform quality. The properties like fat content, temperature, age, pH, previous treatments it has undergone and like are controlled.

ii) Churning the cream

The cream delivered by a cream pump, enters the butter shaft through cream inlet. From this, it goes into the churning cylinder. The butter shaft is driven by a variable speed V-belt drive. In this cylinder, is a four-armed beater running at 250 – 2800 rpm with a wall clearance of 2-3mm. The speed can be varied as required. The pockets in the churning cylinder impart extra turbulence to the film of cream thereby enhancing the butter making action and improving the yield. Butter granules are formed within a 3-5 seconds. The cylinder is cooled by cold water circulation during the operation. Second churning cylinder rotates at 10-25 rpm or stationary cylinder with paddle-bearing shafts rotates at 34 rpm it is also cooled.

iii) Butter milk separation and draining

The mixture of buttermilk and butter granules proceed into the adjoining section known as separating cylinder with its welded in ribs. The next unit is the buttermilk draining cylinder. This cylinder is perforated and provided with beater studs. Buttermilk gets separated and drained through holes.

iv) Washing the granules

The butter granules enter the washing section which is also perforated and has provision for washing spray. The grains which by now reach the finished stage are washed here.

v) Working and texturizing

The washed butter grains fall into twin worm butter worker (two contra rotating screws). They are inclined and forces butter through number of perforated plates arranged in series which gives the fine dispersion of water. The process is assisted by mixing vanes, situated between plates. The butter worker can be operated at either of two fixed speed of approximately 65 and 30 rpm.. In this section, there are provisions for salt and colour addition, moisture corrections etc. The butter comes out in the form of a continuous stream, its shape depending upon that of the outlet spout.

Fig.14.3 The Fritz Process - Continuous Butter Churn

14.3.3 Concentration and Phase Inversion Process

Machines operating on the principle of concentration and phase inversion were introduced after the discovery of Wendt (1932) of high fat cream. He found that normal cream could be re separated to a rich cream with fat content as high as the minimum permissible fat content in butter. Butter formation in the cooling of concentrated cream was observed by Mohr (1931). The Alfa process was developed in Germany and Sweden. The Alfa-Laval (Sweden) butter making process consists of the following major steps (McDowell, 1953).

i) Pasteurization and concentration

Normal cream of 30 – 35 percent fat is pasteurized at 90°C. It then passes through a cream concentrator where the fat content is raised to 80 – 84 percent.

ii) Cooling and phase inversion

The high fat content cream is delivered by the concentrator into the balance tank, which is mechanically stirred continuously. The prepared cream is then drawn and is forced through the transmutator. This consists of a bank of three stainless steel jacketed cylinder provided with mechanically driven rotors. There is an annular space about 0.5 to 0.6 cm wide between the inner cylinder and the rotor. The rotors are fitted with soft metal ribs set in spiral fashion and of such thickness as to scrape lightly the internal surface of the cylinder. The direction of rotation of the rotors is related to the direction of spiral ribbing so as to aid the forward movement of the contents in the annular space. Brine is circulated through the jackets. The cream is kept moving over the cooled surfaces of the cylinders by the revolving rotors. The combined cooling and mechanical action causes butter formation to take place. The butter leaves the transmutator in a semi liquid state, but solidifies rapidly.

The Alfa process is not suitable for acid cream as it clogs the concentrator bowl. It involves some difficulties in control of moisture content of butter (McDowell, 1953).

Fig. 14.4 Alfa process - Continuous Butter Churn

14.3.4 Concentration, De-emulsification and Re-emulsification Process

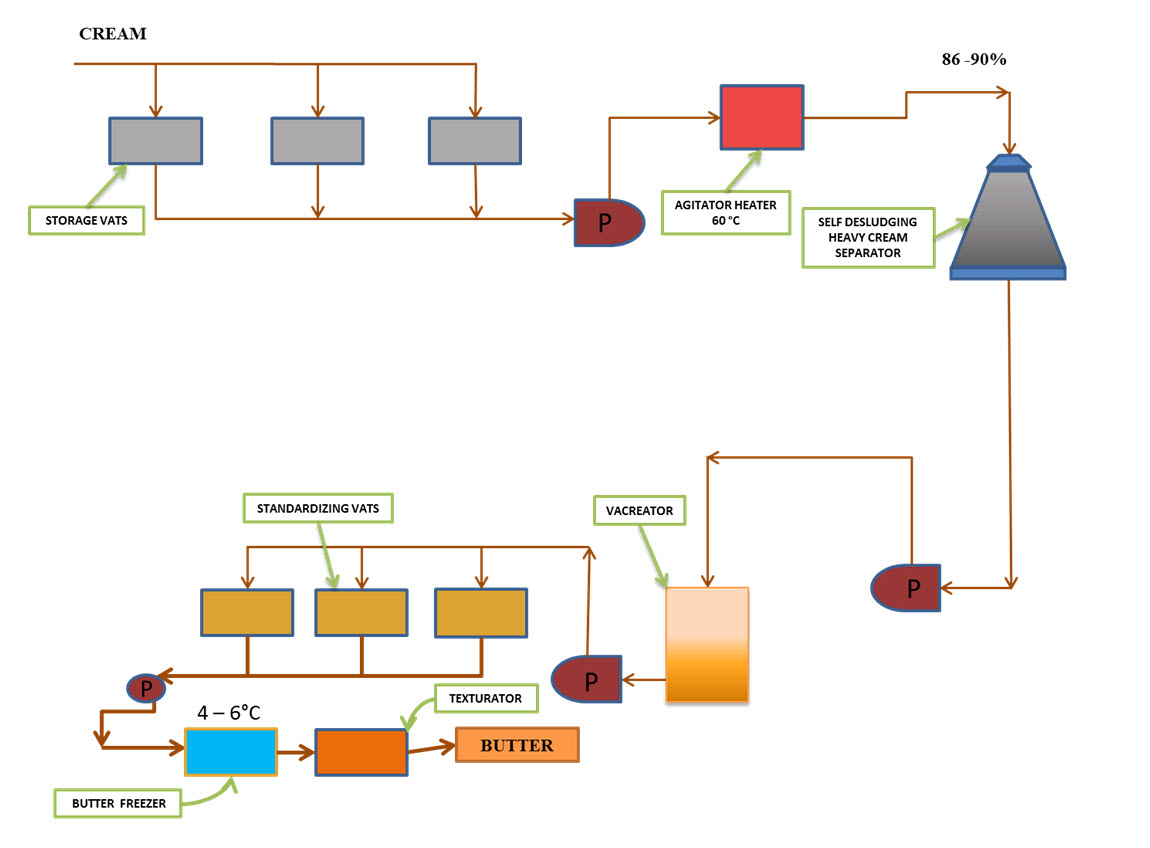

The main steps of Gold’n Flow butter making method are described below (McDowell, 1953).

i) Destabilization

Freshly separated cream of 30 – 40 percent is taken and air is incorporated in it. After this, the cream passes through a destabilizing pump containing perforated rotor blades turning at about 3000 rpm.. Better destabilization is obtained by using two pumps in series. The cream is preheated to 60°C in a vertical centrifugal heater. The preheating is employed to bring the cream to adequate temperature and to complete destabilization. Fat globule membrane is disrupted and weakened by the pump and the destabilization is completed by subsequent heating. Fat then moves as a continuous mass which is free of globular fat.

ii) Concentration

After destabilization cream is concentrated to 85 – 90 percent by a special separator which discharges skim milk, sludge and concentrated cream.

iii) Pasteurization

The concentrated cream is pasteurized in a vacreator at 88 - 90°C and subsequently cooled to 38 – 43°C.

iv) Standardization

The liquid butter fat in which small droplets of cream are dispersed is constantly stirred and standardized for moisture, salt and fat.

v) De-emulsification and Texturisation

The standardized mixture is cooled to 4 - 6°C in a chiller. The chiller consists of two horizontal cylinders, installed side by side, and cooled by direct expansion of NH3. Each cylinder is equipped with an agitator provided with scrapper blades. The moisture is finely disturbed by means of vigorous mechanical treatment.

The required consistency is obtained in the butter by treatment in the texturator. While passing through the texturator, temperature increases by about 2°C, which indicates further crystallization of butterfat. Butter comes out at 4 - 6°C.

Fig.20.4 Gold’n Flow Process - Continuous Butter Churn