Site pages

Current course

Participants

General

Module 1: Introduction and Concept of Soil Erosion

Module 2: Water Erosion and Control

Module 3: Wind Erosion, Estimation and Control

Module 4: Soil Loss- Sediment Yield Estimation

Module 5: Sedimentation

Module 6: Topographic Survey and Contour Maps

Module 7: Land Use Capability Classification

Module 8: Grassed Waterways

Module 9: Water Harvesting

Module 10: Water Quality and Pollution

Lesson 11 Earthen Dam

An earthen embankment is a raised confining structure made from compacted soil. The purpose of an earthen embankment is to confine and divert the storm water runoff. It can also be used for increasing infiltration, detention and retention facilities. Earthen embankments are generally trapezoidal in shape and most simple and economic in nature. They are mainly built with clay, sand and gravel, hence they are also known as earth fill dams or earthen dams. They are constructed where the foundation or the underlying material or rocks are weak to support the masonry dam or where the suitable competent rocks are at greater depth. They are relatively smaller in height and broader at the base.

11.1 Components of An Earthen Dam

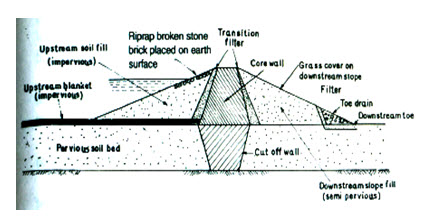

The various components of an earthen dam are shown in Fig. 11.1.

Shell, Upstream Fill, Downstream Fill or Shoulder: These components of the earthen dam are constructed with pervious or semi-pervious materials upstream or downstream of the core. The upstream fill is called the upstream shell and the downstream portion is the downstream shell.

Upstream Blanket: It is a layer of impervious material laid on the upstream side of an earthen dam where the substratum is pervious, to reduce seepage and increase the path of flow. The blanket decreases both the seepage flow and excess pressure on the downstream side of the dam. A natural blanket is a cover of naturally occurring soil material of low permeability.

Drainage Filter: It is a blanket of pervious material constructed at the foundation to the downstream side of an earthen dam, to permit the discharge of seepage and minimize the possibility of piping failure.

Cutoff Wall or Cutoff: It is a wall, collar or other structure intended to reduce percolation of water through porous strata. It is provided in or on the foundations.

Riprap: Broken stones or rock pieces are placed on the slopes of embankment particularly the upstream side for protecting the slope against the action of water, mainly wave action and erosion.

Core Wall, Membrane or Core: It is a centrally provided fairly impervious wall in the dam. It checks the flow of water through the dam section. It may be of compacted puddled clay, masonry, or concrete built inside the dam.

Toe Drain: It is a drain constructed at the downstream slope of an earthen dam to collect and drain away the seepage water collected by the drain filters.

Transition Filter: It is a component of an earthen dam section which is provided with core and consists of an intermediate grade of material placed between the core and the shells to serve as a filter and prevent lateral movement of fine material from the core.

Fig. 11.1. Cross-section of an Earthen Dam with Various Components. (Source: Michael and Ojha, 2012)

11.2 Advantages

Design procedures are straightforward and easy.

Local natural materials are used.

Comparatively small establishment and equipment are required.

Earth fill dams resist settlement and movement better than more rigid structures and can be more suitable for areas where earth movements are common.

11.3 Disadvantages

An earthen embankment is easily damaged or destroyed by water flowing on, over or against it. Thus, a spillway and adequate upstream protection are essential for any earthen dam.

Designing and constructing adequate spillways is usually the most technically difficult part of any dam building work. Any site with a poor quality spillway should not be used.

If it is not adequately compacted during construction, the dam will have weak structure prone to seepage.

Earthen dams require continual maintenance to prevent erosion, tree growth, subsidence, animal and insect damage and seepage.

11.4 Types of Earthen Dam

1. Based on the method of construction:

(a) Rolled Fill Earthen Dams: In this type of dams, successive layers of moistened or damp soils are placed one above the other. Each layer not exceeding 20 cm in thickness is properly consolidated at optimum moisture content maintained by sprinkling water. It is compacted by a mechanical roller and only then the next layer is laid.

(b) Hydraulic Fill Earthen Dam: In this type of dams, the construction, excavation and transportation of the earth are done by hydraulic methods. Outer edges of the embankments are kept slightly higher than the middle portion of each layer. During construction, a mixture of excavated materials in slurry condition is pumped and discharged at the edges. This slurry of excavated materials and water consists of coarse and fine materials. When it is discharged near the outer edges, the coarser materials settle first at the edges, while the finer materials move to the middle and settle there. Fine particles are deposited in the central portion to form a water tight central core. In this method, compaction is not required.

2. Based on the mechanical characteristics of earth materials used in making the section of dam:

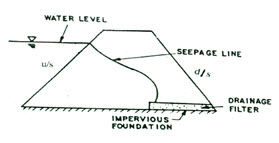

(a) Homogeneous Earthen Dams: It is composed of one kind of material (excluding slope protection). The material used must be sufficiently impervious to provide an adequate water barrier, and the slopes must be moderately flat for stability and ease of maintenance (Fig. 11.2).

Fig. 11.2. Homogenous Earthen Dam. (Source: Michael and Ojha, 2012)

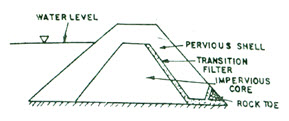

(b) Zoned Earthen Dams: It contains a central impervious core, surrounded by zones of more pervious material, called shells. These pervious zones or shells support and protect the impervious core (Fig. 11.3).

Fig. 11.3. Zoned Earthen Dam. (Source: Michael and Ojha, 2012)

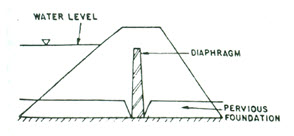

(c) Diaphragm Earthen Dam: This type of dam (Fig. 11.4) is a modified form of homogenous dam which is constructed with pervious materials, with a thin impervious diaphragm in the central part to prevent seepage of water. The thin impervious diaphragm may be made of impervious clayey soil, cement concrete or masonry or any impervious material. The diaphragm can be constructed in the central portion or on the upstream face of the dam. The main difference in zoned and diaphragm type of dams depends on the thickness of the impervious core or diaphragm. The thickness of the diaphragm is not more than 10 m.

Fig. 11.4. Diaphragm Earthen Dam. (Source: Michael and Ojha, 2012)

11.5 Design Criteria

Following main design criteria may be laid down for the safety of an earth dam:

1. To prevent hydraulic failures the dam must be so designed that erosion of the embankment is prevented. For this purpose, the following steps should be followed:

(a) Spillway capacity is sufficient to pass the peak flow.

(b) Overtopping by wave action at maximum water level is prevented.

(c) The original height of structure is sufficient to maintain the minimum safe freeboard after settlement has occurred.

(d) Erosion of the embankment due to wave action and surface runoff does not occur.

(e) The crest should be wide enough to withstand wave action and earthquake shock.

2. To prevent the failures due to seepage:

(a) Quantity of seepage water through the dam section and foundation should be limited.

(b) The seepage line should be well within the downstream face of the dam to prevent sloughing.

(c) Seepage water through the dam or foundation should not remove any particle or in other words cause piping.

(d) There should not be any leakage of water from the upstream to the downstream face. Such leakage may occur through conduits, at joints between earth and concrete sections or through holes made by aquatic animals.

3. To prevent structural failures:

(a) The upstream and downstream slopes of the embankment should be stable under all loading conditions to which they may be subjected including earthquake.

(b) The foundation shear stresses should be within the permissible limits of shear strength of the material.

11.6 Design of Earthen Dam

The preliminary design of earthen dam is done on the basis of past experiences. For designing purpose several parameters, given below should be considered.

Top Width

Free Board

Settlement Allowance

Casing or Outer Shell

Cut-off Trench

Downstream Drainage System

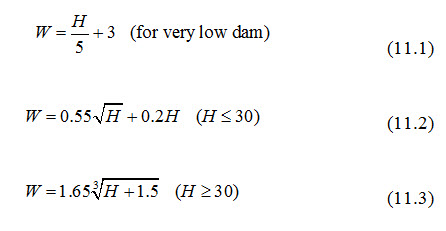

1. Top Width: Minimum top width (W) should be such that it can enhance the practicability and protect it against the wave action and earth wave shocks. Sometimes it is also used for transportation purposes. It depends upon the height of the earthen dam and can be calculated as follows:

where H = the height of the dam (m), for Indian conditions it should not be less than 6 m.

where H = the height of the dam (m), for Indian conditions it should not be less than 6 m.

Free board: It is the vertical distance between the top of the dam and the full supply level of the reservoir or the added height. It acts as a safety measure for the dam against high flow condition that is waves and runoff from storms greater than the design frequency from overtopping the embankment. The Recommended values of free board for different heights of earthen dams, given by U.S.B.R., are given in Table 11.1.

Table 11.1. Recommended Values of Free Board given by U.S.B.R.

|

Nature of spillway |

Height of dam |

Free board |

|

Free |

Any |

Minimum 2 m and maximum 3 m over the maximum flood level |

|

Controlled |

< 60 m |

2.5 m above the top of the gate |

|

Controlled |

> 60 m |

3 m above the top of the gate |

If fetch length or exposure is given then the free board can also be calculated by Hawksley's formula:

![]() (11.4)

(11.4)

where, = wave height (m); Dm = fetch or exposure (m).

2. Settlement Allowance: It is the result of the settlement of the fill and foundation material resulting in the decrease of dam storage. It depends upon the type of fill material and the method and speed of construction. It varies from 10% of design height for hand compacted to 5% for machine compacted earthfill.

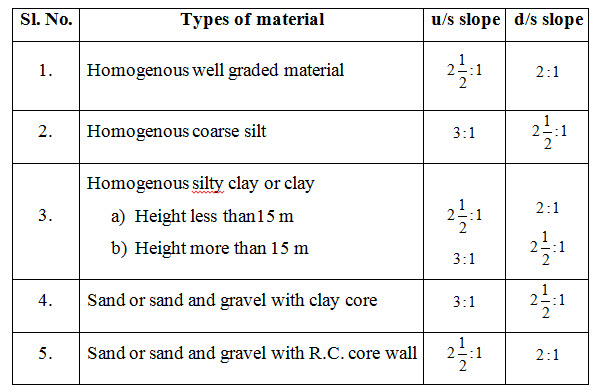

3. Casing or Outer Shell: Its main function is to provide stability and protection to the core. Depending upon the upstream and downstream slopes, a recommendation for the casing and outer shell slopes for different types of soils given by Terzaghi is presented in Table 11.2.

Table 11.2. Recommended Slopes of Earthen Dam (Sources: S.K. Garg, 2008)

Cutoff Trench: It is provided to reduce the seepage through the foundation and also to reduce the piping in the dam. It should be aligned in a way that its central line should be within the upstream face of the impervious core. Its depth should be more than 1 m. Bottom width of cutoff trench (B) is calculated as:

![]() (11.5)

(11.5)

where h = reservoir head above the ground surface (m); and d = depth of cutoff trench below the ground surface (m).

4. Downstream Drainage System: It is performed by providing the filter material in the earthen dam which is more pervious than the rest of the fill material. It reduces the pore water pressure thus adding stability to the dam.

Three types of drains used for this purpose are:

a) Toe Drains

b) Horizontal Blanket

c) Chimney Drains.

Keywords: Earthen Dam, Diaphragm, Zoned, Cutoff Trench, Casing.

References

Michael, A. M., and Ojha, T. P. (2012). Principles of Agricultural Engineering. Vol 2, Jain Bros., 655 p.

Suresh, R. (2009). Soil and Water Conservation Engineering, Standard Publishers Distributors, 951 p.

Garg, S. K. (2008). Irrigation Engineering and Hydraulic Structures. Khanna Publishers, 1057 p.

Suggested Readings

http://www.fao.org/docrep/006/ad082e/AD082e01.htm

http://www.fao.org/docrep/012/i1531e/i1531e01.pdf

http://www.dcr.virginia.gov/stormwater_management/documents/Chapter_3-01.pdf