Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

19 April - 25 April

26 April - 2 May

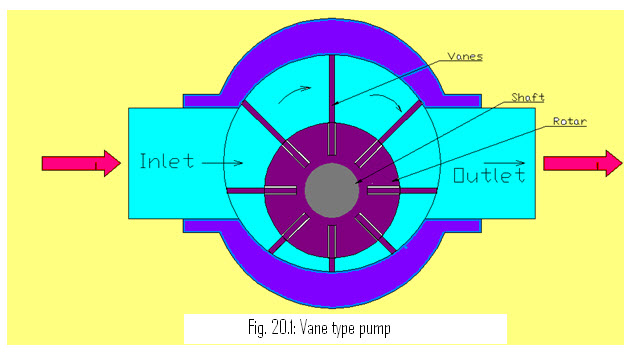

LESSON 22. Design of Vane Pump

22.1 Introduction

Vane pumps are the rotary type of pump which are fitted in the hydraulic systems. In these pumps there is hardly any slippage and the quantity of fluid pumped is nearly same for each rotation of shaft. These are generally positive displacement pumps

22.2 Design of Gear Pump

Gear pump consists of a driving gear and a driven gear enclosed in a closely fitted housing. The gears rotate in opposite directions . Both sets of teeth project outward from the center of the gears. As the teeth of the two gears separate, a partial vacuum forms and draws liquid through an inlet port . Liquid is trapped between the teeth of the two gears and the housing so that it is carried and a force is developed which drives a liquid through an outlet port. Volume of fluid can be calculated as-

Volume of fluid

Let V = volume of fluid

D1 = outer diameter of gear teeth

D2 = inner diameter of gear teeth

N = speed of pump (rpm)

w = gear teeth width

Therefore volume displaced in one revolution V = \[\frac{\pi }{4}(D{1^2} - {\text{}}D{2^{2{\text{}}}})\] x w

Discharge of pump

Discharge per sec . Q = VxN

Efficiency

Efficiency \[\eta\] = \[\frac{{Qa}}{{Qt}}x100\]

Qa = actual discharge

Qt = theoretical discharge

22.3 Vane Pump Design Calculations

The rotary vane pump is consisted of rotor and stator. The stator is the stationary enclosure in which the rotor rotates. The rotor is mounted with eccentric and therefore the rotor makes contact with the stator at the top of the stator between the inlet and the outlet. This point is called the contact point and is actually in close contact separated only by a thin film of oil. The sliding vanes move in and out of the rotor, making contact with the stator surface. The vanes can be spring-loaded or slide by centrifugal force. These are high volume pumps which can pump at higher pressures .When the rotor rotates within the stator , at the inlet of the pump one of the ffallows the fluid to to enter the pump. As it enters inside the pump, the fluid is trapped between the rotor vanes and the stator during rotation, it is pushed out through the outlet of the pump.

22.4 Volumetric Displacement

It can be defined as the product of area and width of rotar. It can be given as-

Let Dc = diameter of cam ring/stator

Dr = diameter of rotor

e = eccentricity

N = speed (rpm)

w = width of rotor

Maximum eccentricity can be given as

emax = \[\frac{{{\text{Dc}} - {\text{Dr}}}}{2}\]

Now volumetric displacement will be- \[A = \pi {r^2}\]

Vd = \[\frac{\pi }{4}(D{c^2} - D{r^2})\] x w

= \[\frac{\pi }{4}(Dc - Dr)\] (Dc + Dr ) x w

= \[\frac{\pi }{4}(Dc + D{r^2})\] x 2emax x w

= \[\frac{\pi }{4}(Dc + D{r^2})\] x emax x w

22.5 Cavitation

Pump cavitation is the formation and subsequent collapse of vapor bubbles in a pump. It occurs when the absolute pressure on the liquid falls below the liquid vapor pressure. When the vapor bubbles collapse with high frequency, it sounds like marbles are moving through the pump. It causes wear and tear and damage to the pump.

22.6 Aeration

Aeration is the presence of air in the hydraulic fluid . It causes the fluid to appear milky and components are to operating erratically. It is because of the compressibility of trapped air in the fluid.