Site pages

Current course

Participants

General

MODULE 1. Overview of renewable energy sources

MODULE 2. Characterization of Biomass

MODULE 3. Thermochemical conversion Technology (TCCT)

MODULE 4. Biochemical conversion Technology-Biogas...

MODULE 5. Bio-fuels (BCCT)

MODULE 6. Solar Energy Conversion System (SECS)

MODULE 7. Hydro-Energy Conversion System (HECS)

MODULE 8. Wind Energy Conversion System (WECS)

MODULE 9. Ocean Energy Conversion System (OECS)

MODULE 10. Energy conservation in agriculture

LESSON 10. Principles of pyrolysis and methods

Pyrolysis

Pyrolysis is the one of the most common methods in thermal conversion technology of biomass. In pyrolysis, biomass is heated to moderate temperatures, 400-600oC, In the absence of stoichiometric oxygen to produce oil that can be used as a feed stock in existing petroleum refineries. This is a high throughput process that has a potential for requiring relatively low capital investment. In gasification, biomass is heated to high temperatures, >700oC, to produce a synthesis gas(H2 and CO), which can be converted in a catalytic step to liquid transportationfuels(mixed alcohols, Fishcher-Tropsch fuels, methanol –to-gasoline etc.).

This technology builds upon decades of experience with gasification of coal. Both approaches have the potential advantages of being relatively insensitive to feedstock type, both suffer from production of unwanted byproducts. In pyrolysis, oxygen-containing compounds (aldehydes, ketones, phenolics and organic acids) make the oil too unstable and acidic for introduction into existing pipelines, tankers and refineries.

Biomass pyrolysis techniques

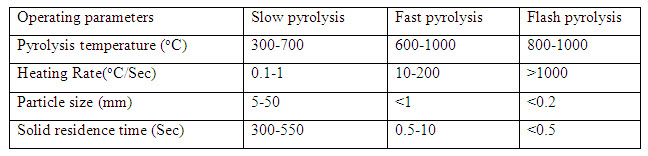

Depending on the operating conditions, the pyrolysis process can be divided into three sub classes. Conventional slow pyrolysis, fast pyrolysis and flash pyrolysis. The range of important operating parameters for pyrolysis processes is given in the following table. At present, the preferred technology is fast or flash pyrolysis at high temperature with very short residence time.

Main operating parameters for pyrolysis process

Pyrolysis processes

Slow pyrolysis

Slow pyrolysis is a conventional pyrolysis process whereby the heating rate is kept slow (approximately 0.1-1 oC/s). This slow heating rate leads to higher char yield than the liquid and gaseous products. Slow pyrolysis has been utilized for thousands of years primarily for the production of charcoal. In slow wood pyrolysis, biomass is heated to ~500 oC.thevapour residence time in the reactor, gas-phase products have ample opportunities to continue to react with other products to form char.

Fast Pyrolysis

Fast pyrolysis uses much faster heating rates (about 10-200oC) and is considered as a better process than slow pyrolysis for producing liquid or gases. In fast pyrolysis the liquid product yield is higher since the fast heating rates allow the conversion of thermally unstable biomass compounds to a liquid product before they form undesired coke. Typically, fast pyrolysis processes produce 60-75 wt% of liquid bio oil,15-20%wt of solid char and 10-20 %wt of non-condensable gases depending on the feed stock used. Fast pyrolysis occurs on the timescale of a few seconds or less. Therefore, chemical reaction kinetics, heat and mass transfer processes and phase transition phenomena play important role in product distributions. Among pilot scale reactors, fluidized bed reactors are best suited for the process as they offer high heating rates, rapid devolatilization and are easy to operate. Other reactors such as entrained flow reactors, circulating fluidized bed reactors, rotating cone reactors etc. are also used for this purpose.

Flash pyrolysis

Flash pyrolysis is an improved version of fast pyrolysis, whereby the heating rates are very high, >1000oC/s, with reaction times of few to several seconds. Present reactors for flash pyrolysis include fluidized bed reactors, vacuum pyrolysis reactor, rotating cone reactor, entrained flow reactor, ablative, vortex or blade, twin screw reactors. Entrained flow or fluidized bed reactors are considered the best reactors for this purpose. Due to the rapid heating rates and short reaction times, for better yields, this process requires smaller particle size compared to the other processes.

Types of biomass pyrolysis reactors

Small-scale pyrolysis devices for fundamental research

1.Resistively heated micro-furnace or tube pyrolyzer

Micro furnaces provide a constantly heated isothermal pyrolysis zone into which samples are introduced by a liquid syringe, solid plunger syringe, or in a little cup. Lack of control of the temperature/time characteristics of the sample has made the continuous-mode pyrolyzer less attractive for precise analytical work. However, the combination of a pulsed molecular beam source with the continuous mode pyrolysis oven overcomes these control problems.

2.Resistively heated element pyrolyser

Filament pyrolyzers can acquire a controlled pyrolysis temperature extremely quickly. An initial pulse of heating at high voltage produces a current through the metal filament causing it to heat rapidly until the programmed pyrolysis temperature is achieved.The pyrolysis temperature is maintained by reducing the voltage. The filament pyrolizer such as a Pt-coil pyrolizer appears to be the mostly used among various commercial models of the pyrolysis reactors. Samples that are soluble in a volatile solvent are pyrolysed using a ribbon probe. Those that are not heated using a coil probe. While samples are added directly on to the ribbon probe, quartz tubes are used to hold the samples before being inserted into the coil probe with regards to the later, the exact pyrolysis reaction time is difficult to determine since the sample never come in to direct contact with the filament.

3.Curie-point filament pyrolyzer

Curie point pyrolyzer utilizesferro-magnetic metals to provide rapid and reproducible heating conditions. The sample is positions on to the end of pyrolysis wire made from an appropriate ferro-magnetic alloy. It is then inserted the pyrolyzer and rapidly heated using a high frequency induction coil. The temperature ceases to rise when the curie-point of the metal has been reached. That is the exact reproducible temperature at which ferro-magnetic material loses its magnetism. At this point the temperature remains constant until the coil is switched off. In contrast to the micro furnace, the rise time of curie-point pyrolyzer is much faster. However, the choice of different pyrolysis temperatures is limited since they are determined by the curie point of available materials.

4.Laser pyrolyzer

The Laserpyrolyser consists of a laser and the associated optical devices , the sample chamber and cold trap. The laser is focused through microscope objective lense and the targeted area is pyrolysed using either a continuous wave or a number of high energy pulses. The thermal interaction between laser and material initiates a shock which in turn produce a range of pyrolysis products. A variety of different laser can be used as a fragmentation source depending on the type of material being pyrolysed. Lasers used for pyrolysis include Nd:YAG laser (1064nm), an rogan ion laser(458-515 nm)and a ArFeximer laser(193nm) to name a few. The use of laser as a fragmentation source has several advantages. Unlike the filament, curie-point and the furnace pyrolyzer, laser pyrolysis requires the very little sample preparationor pre-treatment since analysis is performed directly on the solid polymermatter. The intense, short duration laser beam enables rapid temperature rise times, followed by rapid cooling, reducing the potential for secondary reactions between the pyrolysis products and therby simplifying interpretations of fragmentation patterns. finally, the collimated nature of the laser beam enables focusing to achieve spatial resolutions in targeting specific areas and layers of the sample.

5.Plasma pyrolysis reactor.

Plasma pyrolysis reactor offers some unique advantages for biomass conversion, in comparison to conventional pyrolysis at low temperatures and slow heating rates. The high energy density and temperature associated with thermal plasmas and the corresponding fast reaction times provide a potential solution for the problems that occur in conventional pyrolysis processes, such as low gas productivity and the generation of heavy tarry compounds. Nevertheless, plasma pyrolysis of biomass for energy and chemical production are seldom studied because of the high electrical power consumption. In fact, the temperature initiated in thermal plasma (usually 2500-9500 oC) is much too high for biomass pyrolysis. Recently there was an study which resulted that this type of plasma combines the high plasma reactivity and thermal efficiency with a medium temperature (900-9500oC) and favours hydrocarbon cracking and thus increase the yield of syngas. This method is therefore practical interest for the utilization of biomass material for the purpose of syngas and char production.

Pilot scale pyrolysis reactors

1.Fixed Bed Reactor

Fixed bed reactors were traditionally used for the production of charcoal. Poor and slow heat transfer resulted in very low liquid charcoal yields. These gasifiers are divided into downdraft and updraft fixed bed reactors. Their technology is simple, reliable and proven for fuels with a relative uniform size. In a down draft fixed bed reactor, solid moves slowly down and a vertical shaft and air introduced and reacts at a throat that supports the gasifying biomass. The solid and product gas move downward in a co-current mode. A relatively clean gas is produced with low tar and usually with high carbon conversion. In contrast, the updraft fixed bed reactor is characterized by solid moving down a vertical shaft and contacting a counter-current mode. The product gas is very dirty with high levels of tars although tar crackers have been developed to alleviate this problem.

2.Bubbling Fluidized Bed Reactor

Bubbling fluidized beds, biomass particles are introduced into a bed of hot sand fluidized by a recirculated product gas. The high heat transfer rates from fluidized sand cause rapid heating of biomass particles and some ablation by attrition with the sand particles occurs. The bubbling fluidized bed gasifier is characterized good temperature control and high reaction rates. They have greater tolerance to particle size range. They also have higher particulates and more moderate tar levels in product gastar cracking catalysts can be added to the bed. The bubbling fluidized bed pyrolyzer is characterized by simple construction and operation and is well understood technology. They have good temperature control, limited turn-down capability and provide very efficient heat transfer to biomass particles due to high solid density.

3.Circulating Fluidized Bed Reactor

For circulating fluidized bed reactors, biomass particles are introduced into a circulating fluidized bed of hot sand. The recirculated product gas, sand, and biomass particles move together. The high heat transfer rates from sand ensure rapid heating of biomass particles and ablation is more prevalent than with regular fluidized beds. The circulating fluidized bed gasifier is characterized by all features of the bubbling fluidized bed reactors in addition to higher cost at lower capacity. They are in-bed catalytic processingand circulation of hot solids can cause erosion problems inside the reactor vessel. The circulating fluidized bed pyrolizer is characterized by good temperature control in the reactor. the residence time for the char is almost the same as for vapour and gas.the char is attrited more due to higher gas velocities, which result in high char contents. The produced char is typically separated by cyclone.

4.Entrained flow reactor

Entrained flow fast pyrolysis is in principle a simple technology. however, most of the development of these reactors have not been as successful as had been hoped due to poor heat transfer between the hot gas and soil particles. This reactor can result in very high heating rates of the particles and the residence time can be varied from milli seconds to a few seconds. This gasifier reactor is characterized by a simple design, but costly feed preparation is needed for woody biomass. They require high gas flows in lower liquid yields.

5.Vacuum Furnace Reactor

For this reactor, biomass is thermally decomposed under reduced pressure. The vapours produced are quickly removed from the vacuum and recovered as bio-oil as condensation. This pyrolysis reactor is characterized by longer residence time of solid and short residence times. Other important feature in this reactor includes ability to produce larger paricles than most fast pyrolysis reactors and there is less char in the liquid product due to lower gas velocities. There is also no requirement for carrier gas and the process is mechanically complicated. The typical liquid yields for dry biomass feed obtained in this process are from 35 to 50%.

6.Ablative Reactor

The ablative reactor is characterized by high velocity impact of particle on a hot reactor wall, achieved by centrifugal force or mechanically. High relative motion is achieved between particles and the the reactor wall which is typically less than600 oC.the system is more intensive and the process is mechanically driven so the reactor is so complex.

The ablative pyrolysis reactors have considerable advantages over conventional fluidized bed reactors,

No milling of the biomass is required, because the heat introduced as the particles are pyrolysed as by the direct contact with the hot surface.

They have good heat transfer with high heating rates and relatively small contact surface because compact design.

They have high energy and cost efficiency as no heating and cooling of fluidizing gases is required.

They allow installation of condensation units with a small volume, requiring less space at lower costs.

7. Rotating Cone Reactor

The rotating cone reactor is a noval reactor type for flash pyrolysis of biomass with negligible char formation, in which rapid heating and a short residence time of the solids can be realized. Biomass materials like wood, rice husks or even olive stones can be pulverized and fed tot the rotating cone reactor. Carrier gas requirements in the pyrolysis reactor are much less than for fluid bed and transported bed systems. However, gas is needed for char burn off and for sand transport. Complex integrated operations of three subsystems are required: Rotating cone pyrolyzer, riser for sand recycling, and bubbling char combustor. Like other shallow transported-bed reactors relatively fine particles are required to obtain a good liquid yield. The liquid yields of 60-70% on dry feed are typically obtained. There is no large scale commercial implementation.

8.Auger Reactor

In an auger reactor, hot sand and biomass particles are fed at one end of a screw. The screw mixes the sand and biomass and conveys them along, providing a good control o the biomass residence time. This process does not dilute the pyrolysis products with a carrier or fluidizing gas. However, sand must be reheated in a separate vessel and mechanical reliability is a concern. There is no large scale commercial implementation. The advantage of this reactor include,

- Compact size

- No carrier gas required

- Lower processing temperatures(400oC)

The challenges in this are,

Presence of moving parts in the hot zone,

Heat transfer at a large scale may be a problem.