Site pages

Current course

Participants

General

MODULE 1. Definition,Scope & Importance

MODULE 2. Ecosystem Types,Structure and Functions

MODULE 3. Biodiversity

MODULE 4. Natural Resources

MODULE 5. Environmental Pollution

MODULE 6. Nuclear Hazards -Solidwaste-disasterMana...

MODULE 7. Biosafety And Risk Assessment

MODULE 8. WASTE MANAGEMENT

MODULE 9. GLOBAL WARMING

MODULE 10. ENVIRONMENTAL ACT AND RELATED ISSUES

LESSON 30 MANAGEMENT OF SEWAGE

The major environmental fallout of robust consumption-driven economic growth is the generation of growing amounts of wastes. Many cities and towns are overwhelmed by the increase in the volume of waste that they must manage with every passing year. The accumulation of waste threatens the health of people in residential areas. Wastes are often divided into two major categories: i.e., domestic and industrial wastes. Domestic wastes include domestic sewage, wastes from food processing, detergents and runoff from agricultural areas. Industrial wastes in some cases also identified as hazardous wastes include heavy metals, radioactive nuclides, inorganic chemicals, e-waste and heated water and biomedical wastes from health care institutes and hospitals. Waste decays, encourages household pests and turns urban areas into unsightly, dirty and unhealthy places to live in. Waste waters can be classified by their origin as domestic waste water and industrial wastewater. Any combination of wastewaters that is collected in municipal sewers is termed as municipal sewage.

Domestic sewage is a very serious pollutant of wells and rivers which are important sources of our drinking water. The discharge of sewage can cause public health problems either from contact with polluted water or from consumption of contaminated fish or shellfish. Drinking water sources are often threatened by increasing concentration of pathogenic organisms as well as by many of the new toxic chemicals disposed of by industries and agriculture. The discharge of untreated sewage effluents also produces long term adverse impacts on the ecology of critical coastal ecosystems in localized areas due to the contributions of nutrients and other pollutants. Various constituents of wastewater are potentially harmful to the environment and to human health. In the environment, the pollutants may cause destruction of animal and plant life and aesthetic nuisance. It is essential to know the composition of sewage and its characteristics, etc to decide the treatment type. For proper planning and management of the sewage plants and for designing the various components for effective treatment process the engineer should be acquainted with the properties of sewage and the tests required.

Composition of sewage

Depending on the amounts of physical, chemical and biological constituents of waste water they may be classified as strong, medium, or weak. Composiition of sewage gives an indication of the nuisance value of sewage. It is generally indicated by the following characteristics:

- Total volatile solids, both suspended and dissolved

- Odour

- Biochemical oxygen demand (BOD)

- Chlorine demand

- Chemical oxygen demand

Properties of sewage

Physical Properties

The physical properties of sewage are :

(a) Colour : Fresh domestic seweage is earthy or grey and has a soapy colour. However, After a few hours, due to decomposition the colour changes to black.

(b) Odour : The odour of fresh domestic sewage is slightly soapy or oily but stale sewage gives out an offensive odour.

(c)Temperature: The temperature of sewage is slightly higher than ordinary water. As conduits are closed, the bacterial activity increases due to which the temperature also increases.

(c) Solids: Sewage contains 99.9% of water and only 0.1% of solids. Solids exist in suspension, dissolved or in colloidal form. Colloidal solids are also in suspension but will not settle ordinarily.

Chemical Characteristics

Sewage contains complex organic matter derived from faecus, urine, etc. Organic compounds can be classified as those containing nitrogen and those without nitrogen. Urea, proteins, amines, etc., are nitrogenous compounds, while fats, soaps, carbohydrates are non-nitrogenous compounds, while fats, soaps, carbohydrates are non-nitrogenous compounds. Sewage also contains inorganic materials such as sand, debris etc., obtained from street washing, kitchen washing, etc. It also contains salts and alkalis obtained from bathroom, kitchens and industrial plants. Normally fresh sewage is alkaline in nature but becomes acidic as it becomes stale.

Biological characteristics

Sewage contains living organisms, such as bacteria, algae, fungi and protozoa. Bacteria in sewage carry out the process of breaking the complex organic compounds into simple and stable compounds. There are two types of bacteria: (i) Aerobic bacteria and (ii) Anaerobic bacteria. Aerobic bacteria live in the presence of oxygen dissolved in water in free oxygen. Anaerobic bacteria on the other hand live and carry on their activities in the absence of free oxygen.

The decomposition of sewage takes place in two stages:

- Aerobic decomposition

- Anaerobic Decomposition

- Aerobic decomposition : Aerobic bacteria convert organic matter, waste products, water, etc, in the presence of the dissolved oxygen in the sewage water, initially to nitrogenous, carbonaceous and sulphurous compounds, which are more stable. With the supply of more oxygen, these compounds are further decomposed into more stable nitrites and then to nitrates. Aerobic decomposition is also known as oxidation, because during this process, the organic matter is broken up and oxidised to more stable products. Aerobic bacteria produce gases which are not offensive in odour. When the oxygen supply in the water is exhausted, the aerobic bacteria die. Treatment plants working on the oxidation principle are aeration tanks, contact beds, intermittent sand filters, trickling filters and oxidation ponds.

- Anaerobic Bacteria : When the aerobic bacteria die, anaerobic bacteria start their activity with the oxygen available in the organic matter. These bacteria break up the organic compounds to nitrites, nitrates, proteins, etc. The gases produced in the process are very offensive in odour. Anaerobic decomposition is also known as putrefaction and the end products include black residue called humus, ammonia, methane, hydrogen sulphides, etc. Treatment units which work on the principle of putrefaction are septic tanks, Imhoff tanks, sludge digestion tanks, etc. Plants use the products of decomposition such as carbon dioxide or nitrates to produce chlorophyl. When plants die they are decomposed by aerobic and anaerobic bacteria and so the cycle goes on. Fresh sewage does not have offensive odour. But after a few hours it becomes stale, septic and foul. Hence in sewage treatment, aerobic decomposition is encouraged by supplying oxygen for its activity by the following ways: Allowing sewage to pass through porous medium, and circulating air through the pores as in the case of trickling filters. Adding activated sludge to fresh sewage and blowing air. In a sewage treatment plant, the activity of anaerobic bacteria is controlled so that the odour is not noticeable.

Sewage treatment and disposal

The wastewater treatment processes are generally grouped according to the water quality they are expected to produce. The sewage that is collected from residences, public places, industries, etc., by the separate system or combined system is disposed off by letting it into a body of water such as a river or sea, or on land. But before that, the sewage has to be treated for following reasons. To prevent pollution of water into which the sewage is let off, as the water may be used downstream for drinking water supply. This causes a health hazard as sewage contains pathogenic bacteria. To prevent offensive odour in the water, if the water is used for swimming, boating, etc., To prevent the destruction of fish and other aquatic life. If the sewage has to be disposed off on land, the soil will become sewage sick after some time and cannot take anymore sewage. This creates a very messy scene at the site and produces offensive odour, polluting the entire atmosphere and affecting the neighbourhood.

3.2.1.2. Broad outline of sewage treatment (Fig 3.1.)

These treatment processes can be classified into the following categories.

- Preliminary treatment

- Primary treatment

- Secondary treatment

- Disinfection

Fig. Broad Outline of sewage treatment

a.Preliminary Treatment : Waste water contains floating suspended solids such as rags, wood, metal, plastic, etc. These have to be removed as they interfere with the treatment processes or mechanical equipment. In the preliminary treatment, these suspended impurities are removed.

b.Primary Treatment : Primary treatment to sewage consists of mainly the sedimentation process to remove suspended organic solids. Chemicals are sometimes added in primary clarifiers to assist in the removal of finely divided and colloidal solids or to precipitate phosphorous.

c.Secondary or Biological Treatment: In this category are included processes such as filtration or activated sludge process. Filtration is done in contact beds or intermittent sand filters or trickling filters. It removes finely divided suspended matter. In the activated sludge process, the sewage is biologically treated. A part of the digested sludge is added to the raw sewage together with oxygen which promotes coagulation of the suspended and colloidal matter.

The matter which settles down at the bottom after treatment is called sludge and the liquid is called effluent. The sludge is disposed off in many ways such as sewage farming, letting it into a natural drainage, or sea.

d.Disinfection: Disinfection is carried out if necessary by chlorination to kill the bacteria which remain in the effluent of sewage.

All of above treatment processes may not always be required. The treatment to be given to a particular sewage depends on the nature of the effluent required. This again depends on the mode of disposal. For example, when effluent has to be disposed off into a body of water, the amount of treatment to be given depends on the use of the water. If water is used for drinking purposes on the downstream, complete treatment is essential.

Preliminary Treatment

Preliminary treatment process consists of the following main operations:

- Screening

- Silt and grit removal

- Oil and grease removal

Screening

Sewage admitted to sewage treatment plant and pumping stations should be effectively screened to protect the machinery in the plant and to avoid difficulties in subsequent stages of treatment. Screens are also necessary when raw sewage is discharged into a watercourse without treatment to prevent unsightly and repulsive floating matter being discharged. A screening device consists of flats placed vertically, inclined or curved and spaced at close and equal intervals across a channel through which sewage flows. Screens are mechanically or manually operated. In manually cleaned screens, a perforated platform is provided from which an operator may rake the screenings (collected waste) from the screen. A hand-rake is provided. The screen is placed inclined between 45 and 600 to horizontal. In a mechanically cleaned screen, a mechanical raking device is provided, the inclination of the screen should be between 60 and 900 with the horizontal. The raking mechanism cleans the screens and lifts up the screenings and empties into a trough. The screenings are disposed off by sanitary land fill or incineration.

Grit Removal

Sewage contains inorganic matter such as sand, broken crockery, etc. These enter sewers from storm washings, kitchens, etc. and creates problem in sludge digestion as it combines with the other organic matter in the sludge. It also causes wear and tear on pumps. Grit is removed in grit chamber. Finer particles are removed in the detritus tank.

3.2.1.4. Primary Treatment

The finely divided suspended solids in the sewage are made to settle down by the sedimentation process. Sedimentation tanks may be of two types namely i)Primary sedimentation tanks and ii) Secondary sedimentation tanks

When a sedimentation tank is used for settling suspended solids before biological treatment, i.e., soon after the grit chamber, it is called primary sedimentation tank. When a sedimentation tank is used for settling suspended solids after biological treatment, it is called secondary sedimentation tank. When chemicals are used to hasten the settling of suspended solids, the process is called chemical precipitation. The liquid sewage coming out of tanks after sedimentation process is called effluent. The thick viscous liquid settled at the bottom of the tank is called sludge. Sedimentation tanks are classified as follows: (a) Horizontal flow type and (b)Vertical flow type. The sludge from the bottom is cleared by the following methods: Hand cleaning; Mechanical cleaning and Hydraulic cleaning

Chemical Precipitation

When certain chemicals are added to the sewage, a gelatinous precipitate known as 'floc' is formed which enmeshes the smaller particles and grows in size to form larger particles. These particles then settle down. The process of coagulation or chemical precipitation is carried out in two stages:

(i) In the first stage, the chemical is added to the sewage and agitated briskly so that the chemical is mixed well. (ii) In the second stage, when slow agitation of the mixture for a longer period is done, the chemical mixes initimately with sewage. The particles grow in size and settle down. This process is known as flocculation.

Secondary Treatment

The suspended solids which are a part of the organic matter are removed by preliminary and primary treatments. But the effluent still contains 45-50% of unstable organic matter. The secondary treatment consists in converting the remaining organic matter into stable form by putting aerobic and anaerobic bacteria into action. The methods adopted are broadly classified as: Filtration and Activated sludge process

(i) Filtration and filters

Aerobic bacteria need a contact surface to live and carry out their activity. In the filtration process, the contact surface is a filter media of sand or gravel. The aerobic bacteria present in sewage form a thin film around the media particles and oxidize the organic matter. Sufficient oxygen and food are supplied during the process.

a) Contact beds: A contact bed consists of filtering medium. when the sewage passed over the medium a thin film is produced around the particles. the bacteria present in the film oxidize the organic matter. The contact bed consists of an underground watertight tank. It is filled with gravel, ballast or broken stone. The size of particles varies from 15-40 mm. The depth of bed is about 1.2 m. The sewage from the settling tank is supplied by a siphonic dousing tank which works automatically, serves two or three contact beds. The following operations are carried out in the working of contact beds:

- The outlet drain is closed and the tank slowly filled in about two hours.

- The sewage is allowed to stand on the filtering medium for about two hours for oxidation to take place.

- The filtered sewage is emptied which takes about two hours

- The contact bed is allowed to rest for about 6 hours before being used again.

Efficiency of Contact Beds

Bacteria removal ..... 50 - 75%

Organic matter removal ..... 60 - 80 %

Suspended matter removal ..... 80 - 90%

b) Intermittent Sand Filters : In the intermittent sand filter, the filtering medium consists of sand. The action of the filter is due to:

- Mechanical straining and

- Bacterial action

When sewage is passed over the sand, the zoogleal film is formed around the particles. The aerobic bacteria oxidize the organic matter trapped in the voids and absorb the colloidal matter. Sand is placed in a rectangular pit excavated in earth. The bottom of the pit is sloped towards the under drains (Fig. 3.7). Sand should not be too coarse or too fine. The thickness of the sand layer should be between 750-900mm. Below the sand medium, crushed stone or gravel layer of thickness 150-300 mm is provided. A system of underground drainage of tile pipes is laid to collect the effluent. Generally three to four beds are provided. The sewage is treated for a day and allowed to rest for two or three days in rotation. When the filter gets clogged, anaerobic conditions may develop and hence the top layer of 25mm is raked periodically and replaced with clean sand. When septic conditions occur, the filter is allowed to rest for 1-4 weeks.

Due to the introduction of trickling sand filters, these filters have become obsolete. These are, however, used for small treatment plants where pure effluent is required such as in TB hospitals, hotels, etc. These are also used for treating effluent from coagulated sedimentation tanks or trickling filters to get better effluent.

c) Trickling Filters: A trickling filter is an artificial bed of stone or broken brick material over which waste water is distributed and applied in drops, films or spray through which it trickles to the under drains. A zoogleal film is formed on the surface media. The waste water is applied from troughs, moving distributors or fixed nozzles.

A trickling filter consists of the following parts: 1.A rectangular or circular tank, 2. Under drainage, 3.Ventilators, 4.Filter media and 5. Distributors.

Tank : The tanks may be constructed with concrete or masonry. The floor should be impervious.

Under drainage System : The effluent is collected in the under drainage system and ventilated. It is collected in lateral drains made of hollow concrete or vitrified clay units. It is then collected in the main collecting channel, placed along a diameter or along the periphery (edge).

Ventilators : The filter bed is provided with ventilators along the entire peripher of the filter at 2m centre to centre. They are raised above the media top 75 mm. and covered with cowl.

Filter Media : The filter consists of crushed stone, gravel, slag, broken brick, blocks of inert materials, etc. These are placed in a single or multi-layers.

The waste water may be distributed by rotating arms, or fixed spray nozzles or by a truck running on rails.

(ii) Activated Sludge Process

Activated sludge process is a biological sewage treatment process in which mixture of sewage and activated sludge is agitated and aerated. The activated sludge is subsequently separated from the treated sewage by sedimentation and allowed to go waste or returned to the process as needed. The treated sewage overflows the weir of settling tank.

Activated sludge is that sludge which settles down after the sewage has been freely aerated and agitated for a certain time. This activated sludge contains numerous bacteria and other micro-organisms. The following operations are carried out in the activated sludge process.

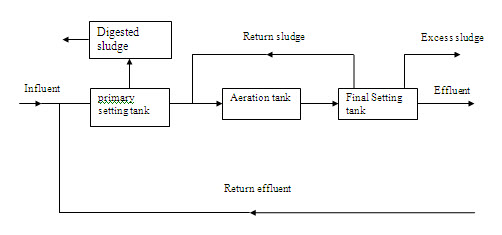

Fig. Activated sludge process

- The raw sewage is given treatment in the primary settling tank. The detention period is kept low, say 1- 1 hours.

- The sewage is then mixed with the required quantity of activated sludge and the mixed liquor is sent to the aeration tank. The mixed liquor is aerated for 4-10 hours according to the degree of purification required.

- The aerated mixed liquor is then sent to the final settling tank where the sludge settles.

- The effluent is disposed off.

- A part of the settled sludge is returned to the aeration tanks to act as activated sludge. The rest of the sludge is disposed off suitably.

Methods of aeration and aerators

The success of the activated sludge process depends on the aeration provided. There are three methods adopted for aeration of sewage:

- Diffused air aeration

- Mechanical aeration

- Combination of the above two methods

(i)Diffused aeration: In this type, compressed air is blown through the sewage by air diffusers. There are two types of diffusers:

- Plate diffusers

- Tube diffusers

Plate diffuser is made of crystalline aluminium or high silica sand of size 300 x 300 x 25 mm. The plate has holes through which air is blown.

Tube diffusers are made of crystalline aluminium about 600mm long. It is suspended into the sewage. Generally the aeration period varies from 3-6 hours. Diffused aeration is used for large installations.

ii. Mechanical Aeration: The surface of the sewage in the aeration tank is agitated. This enables oxygen from the atmosphere to be absorbed. This method is adopted for small treatment plants. Various patented methods are available to produce the requited agitation.

iii. Combination of Air Diffusers and Mechanical Diffusers: In this type, both diffusers and mechanical devices are used for agitating the mixed liquid. Several patented devices are available.