Site pages

Current course

Participants

General

MODULE 1. Definition,Scope & Importance

MODULE 2. Ecosystem Types,Structure and Functions

MODULE 3. Biodiversity

MODULE 4. Natural Resources

MODULE 5. Environmental Pollution

MODULE 6. Nuclear Hazards -Solidwaste-disasterMana...

MODULE 7. Biosafety And Risk Assessment

MODULE 8. WASTE MANAGEMENT

MODULE 9. GLOBAL WARMING

MODULE 10. ENVIRONMENTAL ACT AND RELATED ISSUES

LESSON 33. Management of Hazardous Waste

3.4. MANAGEMENT OF HAZARDOUS WASTES (HW)

According to Supreme Court Monitoring Committee (SCMC) on Hazardous Waste Management 45,00,000 tonnes of hazardous wastes are generated annually in India. 75% of this colossal amount arises from four states – Andhra Pradesh, Gujarat, Maharashtra and Tamil Nadu. Hazardous wastes are so defined because of their special characteristics such as toxicity, corrosivity, flammability and reactivity. The wastes containing certain chemicals, metals and pathogenic organisms (bio-medical wastes) are hazardous in nature. According to the working definition given by WHO, UNEP and world Bank given in 1987, a "Hazardous Waste" is defined as any waste, excluding domestic and radioactive wastes, which because of its quantity, physical, chemical and infectious characteristics can cause significant hazard to human health or the environment when improperly treated, stored, transported or disposed. Hazardous wastes included solids, liquids, gases and sludges that may arise from a wide range of industrial, commercial and agricultural sources. HWs can be classified (Babu and Gupta, 1997) into- (i) Solid wastes (ii) Liquid wastes (iii) Gaseous wastes (iv) Sludge wastes. HPC (2001) defines HW as any substance, whether in solid, liquid or gaseous form, which has no foreseeable use and which by reasons of any physical, chemical, reactive, toxic, flammable, explosive, corrosive, radioactive or infectious characteristics causes danger or is likely to cause danger to health or environment, whether alone or when in contact with other wastes or environment, and should be considered as such when generated, handled, stored, transported, treated and disposed off. This definition includes any product that releases hazardous substance at the end of its life, if indiscriminately disposed off. The HWs can damage the environment, even at low concentrations. The HW needs to be disposed off in a secured manner in view of their characteristic properties. It is necessary to take precautionary measures so that the hazardous components in the wastes are rendered harmless through proper treatment technologies and safe disposal methods.

As per the classification made by the United States Environmental Protection Agency (USEPA), wastes are designated as hazardous if they exhibit the following four characteristics viz, ignitability, corrosivity, reactivity and toxicity. In India hazardous waste generation is maximum in Maharashtra (45.47%) & Gujarat (9.73%) and minimum is reported in Chandigarh (0.0069%). The number of industries that generate HW are maximum in Maharashtra (30.38%) & Gujarat (22.93%). 13011 industries are generating 4415954 TPA of HW in India

The Union Ministry of Environment and Forests notified Hazardous Waste (Management and Handling) Rules, 1989 under Environment (Protection) Act, 1986, to provide a legal framework for ensuring proper management and handling of hazardous wastes. The rules entail definition of hazardous wastes, responsibility of generators and of regulatory agencies, including State Pollution Control Boards, State Governments and the Central Government with regard to collection, storage, transport, handling, treatment and disposal of hazardous wastes. Hazardous Wastes (HWs) are disposed off at Treatment, Storage and Disposal Facility (TSDF), a centralized location catering to the HW generated from the waste generators in the near vicinity. The TSDF will help the small and medium scale industries generating HW in disposing their wastes efficiently. Literature is available on the site selection and other related criteria of TSDF (Ramakrishna and Babu, 1999b; Lakshmi, 1999; Babu and Ramakrishna, 2000; Babu and Ramakrishna, 2003).

Proximate Analysis:

The proximate analysis includes determination of

a) moisture, volatile solids and ash content

b) elemental composition(C,H,N, S,P,F,CI, Br, I)

c) heating value of the waste

d) viscosity or physical form

The proximate analysis data provides valuable information regarding the physical form of the waste and an approximate mass balance on its composition. This also helps in deciding the most appropriate treatment procedure for the waste. It also helps in predicting the likely combustion products(e.g. NOx,SOx,P2O5, halogens, and hydrogen halides) which are of significance.

Survey Analysis

This provides an overall description of the sample in terms of major types of organic compounds and inorganic elements present in the waste and the overall chemistry of the waste sample. This also helps to predict the major POHCs (Products of hazardous constituents) present in the waste and to identify the hazardous by-products of products of incomplete combustion (PICs) or other possible emissions that may require sampling and analysis.

Directed Analysis

The directed analysis is mainly meant for the measurement of designated POHCs in the waste samples. This information is helpful to decide which organic compounds should be anlayzed in the ash and which PICs are to be analyzed in stack emissions.

Analytical Methods

USEPA (1980) document liste 717 hazardous substances (HS) composed of 611 unique chemical compounds and 06 waste streams. Over 300 POHCs are considered among the toxic and hazardous categories of organic compounds. Owing to the complexity of the hazardous wastes, analysis and quantification of specific organic compounds is rather difficult. Mass spectrometer (MS) coupled with gas chromatograph (GC)/liquid chromatograph (LG), Atomic Absorption Spectroscopy (AAS) and Inductively coupled Atomic Emission Spectroscopy are the techniques of choice used for the analysis of various pollutants.

3.4.1. Hazardous Waste Treatment Tehnologies

The following treatment technologies are available for the treatment of hazardous wastes:

i) Physical methods: Physical treatment processes include gravity separation, phase change systems such as air and steam stripping of volatiles from liquid wastes, absorption, reverse osmosis, ion-exchange, electrodialysis.

ii) Chemical methods: Chemical methods usually aim at transforming the hazardous waste into less hazardous substances using techniques such as pH neutralization, oxidation or reduction, and precipitaion.

iii) Biological methods: Biological treatment methods use micro-organisms to degrade organic pollutant in the waste stream.

iv) Thermal Methods: Thermal destruction processes that are commonly used include incineration and pyrolysis. Incineration is becoming a more preferred option. In pyrolysis, the waste mateiral is heated in the absence of oxygen to bring about chemical decomposition.

v) Fixation/Immobilization/Stabilization techniques involve dewatering the waste and solidifying the remaining material by mixing it with a stablizing agent such as portland cement or a pozzolanic material, or vitrifying it to create a glassy substance. For hazardous inorganic sludges, solidification process is generally used.

i) Physical Methods

(a) Sedimentation: Gravity settling and flotation (natural or by employing finely divided air bubbles) are the simplest physical treatment system used to achieve solid - liquid separation. Several types of special sedimentation tanks and clarification tanks are designed to encourage solids to settle at the bottom which can be collected as a sludge. In flotation some solids can be floated with the help of tiny air bubbles which can be skimmed from the surface. The sludges separated by any of the above two methods can be further concentrated by evaporation, filtration or centrifugation.

(b) Adsorption: Small quantities of dissolved organic hazardous wastes can be removed by adsorption. Granular activated carbon (GAC) which has an enormous surface area (about 1000 m2/g) is most commonly used as an adsorbent. Contaminated water is allowed to trickle down through the GAC packed in a series of vessels. The hazardous organics in polluted water are adsorbed on the porous GAC matrix. The GAC filter after some time gets clogged with the adsorbed contaminants and hence must be replaced or regenerated or disposed properly. Regeneration is usually done by burning the contaminants from the surface of the absorbent granules or using a solvent.

(c) Aeration : This technique is used to drive volatile contaminants out of waste solution. Contaminate waste solution is sprayed downward through a suitable packing material in a tower while air is blown upward which carries away the volatile materials with it. Such packed - tower air - stripper can remove over 95% volatile organic compounds (VOCs) such as trichloroethylene, benzene, toluene, trichlorethane, and other organics derived from solvents.

In the induced - draft stripper contaminated water is sprayed through a series of nozzles horizontally from the sides of a chamber, while air passing through it drawn off the volatile.

By passing contaminated water first through an air stripper and then through granulated activated carbon adsorption system, many volatile and non-volatile organic contaminants can be removed from waste water to undetectable levels.

(d) Ion-exchage : This technique is often used to remove toxic metal ions form solution.

(e) Electro-dialysis : This technique uses ion-selective membranes and an electric field to separate anions and cations in solution. This technique, which was mostly used for desalination of brackish water, is now used in the field of hazardous waste treatment. Removal of metal salts from plating rinses is an example.

(f) Reverse osmosis : This device uses pressure to force contaminated water through the pores of a semi-permeable membrane while restricting the passage of larger contaminant molecules. This process is particularly effective for removing dissolved solid contaminants from waste waters.

ii) Chemical Methods

Chemical methods for treating hazardous waste have the dual advantages of converting it to less hazardous forms and also to recover useful by-products in some cases which may offset a part of treatment costs.

(a) Neutralization : As per Resource Conservation and Recovery Act (RCRA), hazardous wastes comprise of such wastes which are corrosive and having a pH of less than 2 or more than 12.5. Such wastes can be rendered less hazardous by chemical neutralization. Acidic wastewaters are usually neutralized with slaked lime. Alkaline wastewater may be neutrlized by adding acid directly or by bubbling in gaseos CO2 which forms carbonic acid (H2CO3). CO2 has an advantage that it is gaseous CO2 which forms carbonic acid directly or by bubbling in gaseous CO2 which forms carbonic acid (H2CO3). CO2 has an advantage that it is generally available readily in the exhaust gas form any combustion process at the treatment site. Simultaneous neutralization of acidic and caustic waste can be accomplished in the same reaction vessel.

(b) Chemical precipitation : The solubility of toxic metals in a waste stream can be decreased, leading to the formation of a precipitate that can be removed by settling and filtration. Precipitation of toxic metals as their hydroxides using lime is the most common metal removal process used.

Each metal has its own optimum pH for precipitation as hydroxide with minimum solubility. Therefore, it is tricky to control precipitation of metals from a hazardous waste containing a mixture of toxic metals.

Precipitation of metal ions in hazardous waste has an advantage to achieve much lower metal ion concentrations in the effluent because metal sulfides have much lower solubility as compared to the corresponding metal hydroxides. However, sulfide precipitation has a disadvantage because of the possibility of formation of odorous and toxic H2S gas.

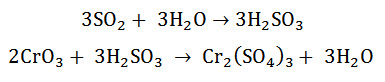

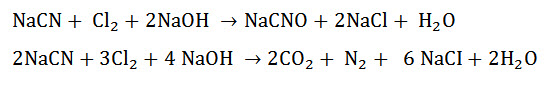

(c) Chemical reduction-oxidation: Redox reactions offer another important alternative for chemical treatment of hazardous wastes. Trivalent chromium ions are for less toxic and more easily precipitated than hexavalent chromium. Therefore, chromium (VI) from electroplating effluents is reduced to Cr(III) using a reducing agent as SO2:

Another important redox treatment system, commonly used in metal finishing industry, is the oxidation of cyanide wastes. The cyanide is oxidized to less toxic cyanate using alkaline chlorination. Further, chlorination oxidizes to CO2 and N2, thereby accomplishing total destruction of the hazardous cyanide.

Wastes that can be successfully treated via oxidation include benzene, phenols, cyanide, As, Fe, Mn and most organics, while those which can be treated via reduction include Cr(VI). Hg, Pb, Ag, chlorinated organics like Polychlorinate biphenyls (PCBs), and unsaturated hydrocarbons.

iii) Biological Treatment:

Biological treatment systems use micro-organisms, mainly bacteria, to metabolize organic matter, converting it to , water and new bacterial cells. The microbes need a source of carbon and energy, which they can get from the organics that they consume, as well as nutrients such as N and P. They are sensitive to temperature and pH. some of them need oxygen. Although, living organisms are susceptible to toxic substances, it is surprising that most hazardous organisms can be established and maintained. For any given organic substance, there may be some organisms that accept that substance as an acceptable food supply, while others may find it toxic. Further, organisms that flow with the substance at one concentration may die when the concentration is increased beyond some critical level. Moreover, even though a microbial population has been established to handle a particular type of organic waste, it may be destroyed if the characteristics of the waste are changed too rapidly. However, if changes are made slowly enough, selection pressures may allow the microbial consortium to adjust to the new conditions and thereby retaining their effectiveness.

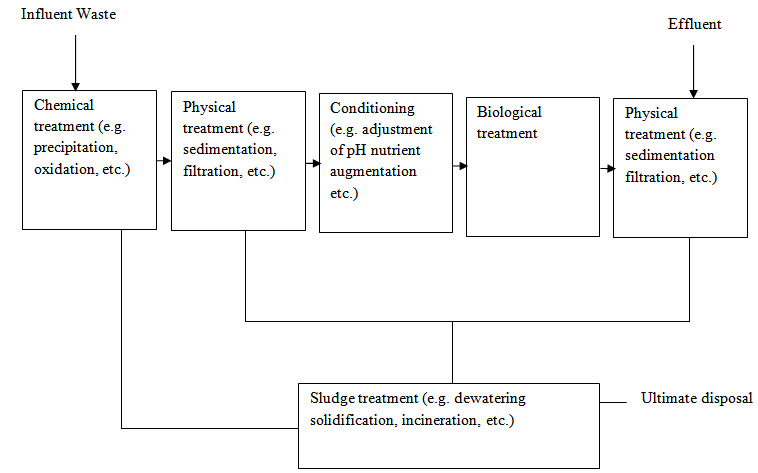

Biological treatment of a hazardous wastewater (e.g. leachates from hazardous waste landfills) is just one of the steps in an overall treatment system, as shown in the flow sheet given below:

General flow sheet for the treatment of liquid hazardous waste

"In Situ" Bio-degradation

To clean a contaminated aquifer, the following techniques are available: One is to pump out the ground water, treat it, and then either re-inject it back into the ground or find some acceptable way to reuse it, or dispose off the treated water in a suitable way.

Another method is to treat the contaminated soils above the aquifer by removing huge quantities of the soil from the site, then treating and disposing them elsewhere.

A relatively new promising alternative to the above two approaches is to move the treatment system to the site of contaminated soil and water. This can be accomplished by "In situ biodegradation" wherein suitable bacteria are used to degrade the organic contaminants in the soil and groundwater on the contaminated site itself. The following two approaches are used to achieve this process: First one is to enhance the environment of existing microbial populations by supplying necessary nutrients to the contaminated aquifer. Oxygen supply can be enhanced if necessary by injecting an oxidant such as H2O2 or by forcing air through wells with diffusers. The second approach is to alter the underground microbial population by seeding with new micro-organisms that have acclimated to the pollutants to be degraded. These new microbes can be selected on the basis of laboratory studies. Genetically altered microbes may be of great potential for this purpose. "In sit" biodegradation has been successfully used to treat soil contaminated with gasoline and diesel oil. It also shows great promise to treat trichlorecthylene, tetrachloroethylene and 1,2-dichloroethylene which are the most commonly found contaminants in underground water supplies.

iv) Incineration

This is a technology of choice for treating many types of hazardous organic wastes present in soils and other solids, liquids, gases, slurries and sludge. However, this process is not capable of destroying inorganic wastes, although it can concentrate them in ash, which can be transported and disposed more easily. A number of types of hazardous waste incinerator are the two designs which are most popular. Inspite of numerous controls, hazardous waste incinerators may emit noxious gases, products of incomplete combustion, odors, and particulates.

v) Land disposal

The various land disposal techniques used for containing hazardous wastes include landfills, surface impoundments, injection wells, and waste piles.

(i) Land fills : Hazardous waste landfill is now designed as a modular series of three dimensional control cells. Compatible waste only can be disposed together and others can be segregated in separate cells. The wastes dumped in the appropriate cell can be covered by a layer of cover soils at the end of each working day. Below the hazardous wastes dumped in every cell, a double liner system is provided to prevent the leachate from polluting the soil and groundwater beneath the site. The upper liner must be flexible - membrane lining made of plastic (eg. PVC, high density polythylene or chlorinated polyethylene) or rubber (e.g. chlorosulfonated polyethylene and ethylene diene monomer). Re-compacted clay of more than 3 feet thickness is also used as FML. Leachate that accumulates above each liner is collected in a series of perforated drainage pipes and pumped to the surface for treatment. A low permeability cap is placed over each completed cell to minimize the amount of leachate due to the rain water seeping into the cell. The possibility of contamination of the ground water beneath the landfill due to the leachate should be continuously monitored.

(ii) Surface impoundments: These are popular because they are cheap and the wastes stored in them are accessible for treatment (e.g. neutralization, precipitation, settling, and biodegradation) during storage. Surface impoundments are nothing but excavated or diked areas used to store liquid hazardous wastes. Storage in these facilities is usually temporary unless the impoundment is designed to be eventually closed as a landfill. Modern surface impoundment facilities are provided with liners, leachate collection system and monitoring programs similar to those of landfills.

(iii) Underground injection : The most popular way for disposal of liquid hazardous wastes is to force them underground at least below 700 m from the surface through deep injection wells. However, stringent regulations have to be followed to ensure prevention of contamination of ground water.

Recovery of useful materials from hazardous wastes is desirable for environmental and economic reasons. Over the years, this has become a thriving business all over the world. But there is a basic difference in the methods adopted in various countries. While industries in developed countries have adopted state-of-art technologies with environmental safeguards, entrepreneurs in developing countries, particularly those in the small scale sector, continue to operate with crude technologies paying scant regard to environmental safety. Industries in some countries prefer to export their wastes to other countries. This has lead to increased trade in trans-boundary transfer of wastes, particularly to the developing countries. The Basel Convention came about in response to the growing concern for regulating transboundary transfer of hazardous wastes and for promoting environmentally sound management practices. We must take preventive measures which are much less expensive than the curative ones. Sector-wise inventorisation and characterization of hazardous wastes, assessment of available facilities for recovery, recycling and reuse, identification of appropriate technologies for different categories of wastes, framing codes of practices and incentives for promotion of environmentally sound methods are among the priority areas for ensuring safe management and handling of hazardous wastes.

Hazardous Wastes Management – Maharashtra

India's biggest landfill for hazardous waste at the privately owned Mumbai Waste Management Limited (MWML) is in Taloja, in Raigad district near Mumbai.Over the 16m high damp of toxic waste, imported 2mm thick HDPE sheets with double scam are laid. This in turn consists of a series of complicated water tight layers that will ensure the hazardous waste does not leach into the soil or groundwater. Over the black HDPE sheets, a composite lining consisting of a layer of geo-synthetic clay liner and geo-net is placed. The final layer will be of vegetation soil and by the time the capping is over, the waste will be in the form of a pyramid with green lawn grass growing all over it. In front of the dump is the only incinerator in Maharashtra used for wastes with high calonfic content. The 100 acre complex has the common hazardous waste treatment, storage and disposal facility. The Rs.54 crore-project operational since November 2004 is run on a build, own, operate and transfer (BOOT) basic by the Hyderabad based Ramky Rroup. It has an annual capacity of 1.2 lakh metric tones of waste while the Rs.12 crore special incinerator can burn wastes of a calorific value of 2,500 kilo calories per kg and has a capacity of 20,000 metric tones per annum.

The air and water quality are monitored by the Central Pollution Control Based (CPCB) once in 2 months, by MPCB once in a month and by the company twice a month. Hazardous wastes from many industrial estates are sent to Tabja. The company charges Rs.787 per tonne of waste for the landfill and this cost increases from Rs.1500-3000 if waste has to be treated. The cost of incineration ranges from Rs.14000-25000 per tonne depending on the calorific value of the waste. The project will accept waste for the first 20 years and there will be a 30 year environmental monitoring period after that. After 90 years it will be handed over to the MPCB and MIDC for management.