Site pages

Current course

Participants

General

MODULE 1. Definition,Scope & Importance

MODULE 2. Ecosystem Types,Structure and Functions

MODULE 3. Biodiversity

MODULE 4. Natural Resources

MODULE 5. Environmental Pollution

MODULE 6. Nuclear Hazards -Solidwaste-disasterMana...

MODULE 7. Biosafety And Risk Assessment

MODULE 8. WASTE MANAGEMENT

MODULE 9. GLOBAL WARMING

MODULE 10. ENVIRONMENTAL ACT AND RELATED ISSUES

LESSON 34. Nuclear Waste Management

3.4.2. Nuclear waste management

Nuclear wastes can be divided into natural and manmade sources. Natural source may be cosmic radiation from space or naturally occurring isotopes in the Earth’s crust. Wastes from manmade sources are arising from mineral processing of radioactive elements, medical, nuclear explosion and atomic power plants. There are three types of nuclear wastes namely Low level; Medium level and High level waste. Nuclear wastes produced in power reactors is in the form of fission products which are sealed within the spent fuel bundles. Once these bundles are discharged from the reactors they are extremely radioactive due to the decay of fission products and transuranic isotopes and their daughters. some of the decay energy is transmitted to the uranium matrix. Thus, the fuel must be cooled to prevent a rise in the cladding temperature to a point where it could react chemically in the atmosphere and lose its integrity. The cooling is accompanied by immersing the bundles in water in a spent fuel storage bay. The water serves as a radiation shield as well. Thus fuel handling can be carried out from above the surface of the pool without the need for any additional shielding.

3.4.2.1. Mine and mill tailings

The storage and disposal of tailings is dependent on local climate, topography and geology and on the nature of the mining operation, e.g., whether it is underground or open pit. The proximity of populated areas will also have an impact on the engineering design.

In the arid regions of the south western United States, emphasis is placed on disposal of tailings in a depression below ground level followed by covering the deposit with a protective thickness of soil, sand, gravel, or crushed rock. The exact requirement will not known until specific regulations relating to random containment have agreed upon by various regulating bodies.

Tailings management in areas when precipitation is higher, such as Eilliot Lake, Canada is focused on designs which minimize dissolution of Ra-226, toxic metal ions and other contaminants such as sulfates and chlorides.

Most of the technology is available to design and construct secure facilities for uranium mine and mill tailings disposal. Intensive research and development efforts are continuing in uranium producing countries to produce the data to ensure that uranium mine and mill tailings will not present a hazard to humans or to environment.

Refinery and fuel fabrication wastes

Refineries purifying Uranium concentrates from the mines generate small amounts of uranium bearing wastes. These wastes are normally accepted back into the milling circuit a mill sites, since the material is equivalent to high grade ores from many mines. Another product of the refinery operation is ammonium nitrate. Its uranium content is reduced in the chemical processes involved to a concentration below that normally found in commercial fertilizers so that it can be marketed as an acceptable agricultural product.

In fuel fabrication operations, a small amount of uranium oxide waste is produced as a result of the pressing, sintering and grinding operations. It is simply recycled through the fabrication process by dissolution in nitric acid, precipitation as ammonium di-uranate, and conversion to unranium dioxide powder. In effect, the circuit is a closed one, with no significant uranium wastes escaping to the environment.

3.4.2.3. Spent fuel

During the first one or two years after discharge form the reactor, the heat flux from the decaying fission products is sufficiently high to make underground storage the most desirable option. As time passes, another possibility is interim dry storage in concrete flasks. The specific route for interim storage will be determined by economics and the proposed ultimate deposition of the spent fuel. The most economical method would be to store fuel underwater for perhaps the first 50 years. Another view, that dry storage in concrete canisters may offer a more economical option, for even longer storage times. Either method, however, offers the advantage of retaining the fuel bundles in readily recoverable form should repress the fuel to separate and recycle the fissionable plutonium become desirable in the future.

The waste disposal process envisaged is one which takes advantage of multiple barriers to fission-product release to the environment. The technology also exists to permit separated fission products from chemical reprocessing operations to be incorporated with glass or ceramic blocks for safe disposal. From available information, chemical compositions and mineralogical structures can be chosen that should remain essentially inert to underground water dissolution for periods counted on a geological time scale.

The government of India has promulgated various rules and guidelines on the management and handling of hazardous waste. These rules are implemented through the State Pollution Control Boards (SPCBs) and Pollution Control committees in the state and Union territories. The strategies recommended are as follows:

Scientific management of hazardous waste including its generation, segregation, transportation, treatment and disposal should be ensured with minimization/reduction of waste as its primary target.

Quantifying and characterizing the volume of waste generated by industries. Training and building the capacity of SPCB officials are required to prepare such an inventory waste.

To minimize the impacts of waste on human health and ecosystem by comprehensive environmental and social assessment of hazardous waste management operations.

To develop adequate infrastructure for the proper treatment and disposal of willingness-to-pay issues by the participating industries, type of ownership, financial mechanisms to finance such ventures, and the extent of private sector participation need to be addressed to ensure that such facilities come into existence.

To reduce the generation of solid waste at source through mandatory standards and regulation, fee and tax incentives, and education and voluntary compliance.

To develop technologies for waste collection, treatment and disposal in order to ensure proper solid-waste management.

Standards must be set up to clean the contaminated soils and groundwater.

BIO MEDICAL WASTE MANAGEMENT

In April 1995 the Ministry of Environment and Forests (MoEF) woke up to the threat of a health hazard from a grossly mismanaged hospital wastes disposal system and proposed legislation to make incineration of infectious medical wastes mandatory for hospitals.

Biomedical waste, (BMW), consists of solids, liquids, sharps, and laboratory waste that are potentially infectious or dangerous and are considered biomedical waste. It must be properly managed to protect the general public, specifically healthcare and sanitation workers who are regularly exposed to biomedical waste as an occupational hazard.

Biomedical wastes from hospitals and other medical facilities such as clinics, research laboratories and drug companies induce the following pathological and infectious wastes.

Pathological land surgical wastes

Experimental animals and cadavers.

Drug and chemical residues and containers.

Discarded linens, clothing and bandages.

Disposable needles, syringes and surgical instrument.

Contaminated equipment, food and other wastes

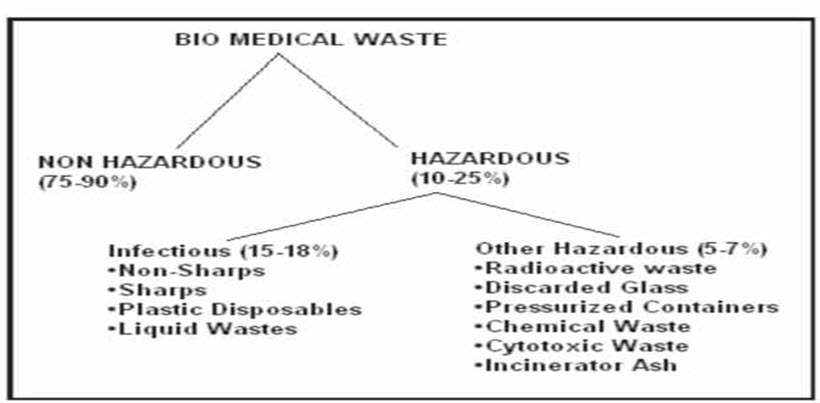

Approximately 75-90% of the biomedical waste is non-hazardous and as harmless as any other municipal waste. The remaining 10-25% is hazardous and can be injurious to humans or animals and deleterious to environment. It is important to realise that if both these types are mixed together then the whole waste becomes harmful.

Chemical and chemotheraphy wastes, organic wastes (solvents) and radioactive wastes are not usually considered as biomedical wastes and regulated under different legislation. Solid wastes from hospitals have been estimated by the American Public Works Association (1970) to be about 5kg per patient per day, with hazardous wastes accounting for two or four percent of this.

Classification of hospital waste

(1) General waste: Largely composed of domestic or house hold type waste. It is non-hazardous to human beings, e.g. kitchen waste, packaging material, paper, wrappers, plastics.

(2) Pathological waste: Consists of tissue, organ, body part, human foetuses, blood and body fluid. It is hazardous waste.

(3) Infectious waste: The wastes which contain pathogens in sufficient concentration or quantity that could cause diseases. It is hazardous e.g. culture and stocks of infectious agents from laboratories, waste from surgery, waste originating from infectious patients.

(4) Sharps: Waste materials which could cause the person handling it, a cut or puncture of skin e.g. needles, broken glass, saws, nail, blades, scalpels.

(5) Pharmaceutical waste: This includes pharmaceutical products, drugs, and chemicals that have been returned from wards, have been spilled, are outdated, or contaminated.

(6) Chemical waste: This comprises discarded solid, liquid and gaseous chemicals e.g. cleaning, housekeeping, and disinfecting product.

(7) Radioactive waste: It includes solid, liquid, and gaseous waste that is contaminated with radionuclide’s generated from in-vitro analysis of body tissues and fluid, in-vivo body organ imaging and tumour localization and therapeutic procedures.

Objective of Biomedical Waste Management

To prevent transmission of disease from patient to patient, from patient to health worker and vice versa

To prevent injury to the health care worker and workers and workers in support services, while handling biomedical waste

To prevent general exposure to the harmful effects of the cytotoxic, genotoxic and chemical biomedical waste.

Steps to be followed for Biomedical Waste Management

Segregation and safe containment of waste at the health facility level

Processing and storage for terminal disposal

Bio-medical waste shall not be mixed with other wastes.

Segregation at source – both at ward and unit level

Color coding to support segregation at source

Bio-medical waste shall be segregated into containers/ bags at the point of generation in accordance with Schedule II (BMW Rules 1998) prior to its storage, transportation, treatment and disposal.

The containers shall be labeled according to Schedule III (BMW Rules 1998)

Transport waste safely to pick up site

Identify destination for each type of waste and ensure safe disposal

Keep track of usage

Control of Biomedical Wastes

Control of biomedical wastes is based on guidelines practiced in different countries, such as US 1985 Guidelines for infectious waste management and the Canadian 1986 Guidelines for the Handling and Disposal of biomedical wastes. Enactment and enforcement of regulations governing the collection, processing, transport, and disposal of biomedical waste are generally the responsibility of the community in which the facilities are located. Arrangements for onsite handling of wastes and offsite disposal are left to the waste generators.

For hospitals, the normal practice is onsite incineration of combustible solids in a specially designed high temperature incinerator with after-burners to heat the gases leaving the chamber to at least 7000 C for odor control. As disposal is to a sanitary landfill, wastes from hospitals lacking incineration or sterilization facilities are segregated and packaged in special color coded and labeled containers for transportation and treatment elsewhere prior to land filling.

TRANSPORT TO FINAL DISPOSAL SITE

Transportation from health care establishment to the site of final disposal in a closed motor vehicle (truck, tractor-trolley etc.) is desirable as it prevents spillage of waste on the way. Vehicles used for transport of BMW must have the “Bio-Hazard” symbol and these vehicles should not be used for any other purpose.

DISPOSAL OF BIO MEDICAL WASTE PRETREATMENT

The infected waste that can not be incinerated (e.g. Plastic and rubber items, sharps) has to be disinfected first, before it is sent for final disposal.

FINAL DISPOSAL

Incineration is a high temperature dry oxidation process, which reduces organic and combustible waste to inorganic incombustible matter. This method is usually used for the waste that can not be reused, recycled or disposed of in landfill site.

Characteristics of waste suitable for incineration are:

1.Low heating volume – above 2000 Kcal/Kg for single chamber incinerators and above 3500 Kcal/Kg for pyrolytic double chamber incinerators.

2.Content of combustible matter above 60%.

3.Content of non combustible matter below 50%.

4.Moisture content below 30%.

LANDFILL DISPOSAL

It is another method of final disposal of BMW. If a municipality or medical authority genuinely lacks the means to treat the waste before disposal, sanitary landfill observing certain standards can be as an acceptable choice especially in developing countries.

Standards for deep burial

A pit or trench should be dug about 2 meters deep. It should be half filled with waste, then covered with lime within 50 cm of the surface, before filling the rest of the soil with soil.

It must be ensured that animals do not have any access to burial site.

On each occasion, when wastes are added to the pit, a layer of 10 cm of soil shall be added to cover the wastes.

Deep burial site should be relatively impermeable and no shallow well should be close to the site. The site should be away from the residential area and the vicinity of drinking water so as to avoid the risk of pollution.

The location of deep burial site will be authorized by the prescribed authority.

The institution shall maintain a record of all pits for deep burial.