Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

LESSON 20. Design of Gear Pump

20.1 Introduction

Most of the hydraulic systems are generally provided with positive displacement pumps. In these pumps there is hardly any slippage and the quantity of fluid pumped is nearly same for each rotation of shaft. Specially piston pumps exhibit this quality. The piston sucks and pushes the same quantity (volume) of fluid every rotation of shaft.

20.2 Design of Gear Pump

Therefore,

Q = V x N

Where, Q = Flow rate

V = Displacement

N = speed

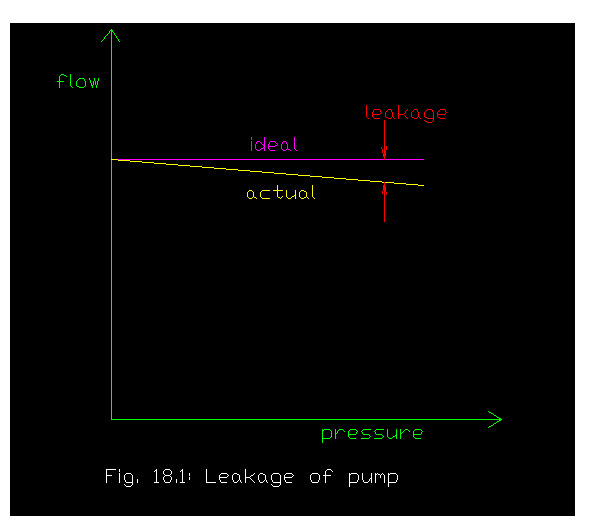

In actual practice there may be some leakages because of mating components are not perfect fits and therefore, the leakage occur in valves or pistons. The leakage will be more with the increase in pressure , as in fig . .

20.3 Volumetric Efficiency

The volumetric efficiency may be defined as the ratio of actual flow rate to the theoretical flow rate

Let

Qa = actual flow rate

Qt = theoretical flow rate

\[\eta \]vol = volumetric efficiency

\[\eta \]vol = \[\frac{{{\text{Qa}}}}{{{\text{Qt}}}}\] x 100

The piston pump is the most suitable example of positive displacement pump but other pumps like gear pump, lobe pump, screw pump and vane pump also come under the same category and calculations can be made accordingly.

20.4 Power of the Pump Shaft

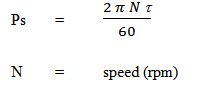

It can be defined as the mechanical power transmitted to the pump shaft by the shaft of power source. It is basically product of torque and speed of the shaft. Hence it can be given as –

Ps = ω x t

Ps = shaft power

ω = angular speed

t = torque

The angular speed of the shaft isfined as the in radians per second and torque transmitted is in Nm. Now if the torque is transmitted in Nm and speed in revolution per second (rpm) the the equation can be deduced as below-

20.5 Fluid Power Calculations

It can be defined as the energy per second by the fluid in the form of pressure and the quantity of fluid. It is product of fluid quantity (flow rate) and the differential pressure. Hence

Pf = Q x Dp

Where Pf = Fluid power

Q = flow rate , m3/s

Δp = differential pressure, N/m2

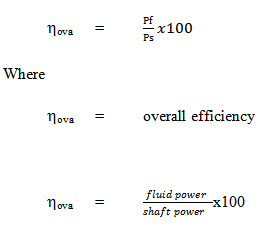

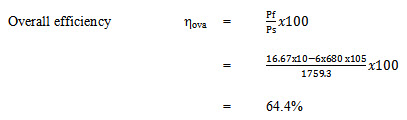

20.6 Overall Efficiency

It can be defined as the ratio of fluid power to the shft power or in other words ratio of output power to the input power. The input power is greater than the ouput power due to leakages in the sysem and friction between the moving parts. Hence overall efficiency can be given as-

Example 1

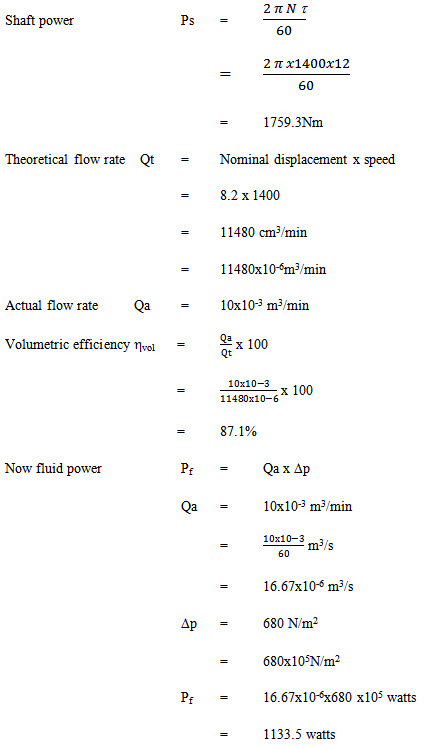

A pump delivers 10x10-3 m3 /min with a pressure rise of 680 N/m2 .The shaft speed of 1400rpm and the nominal displacement is 8.2 cm3/rev. The applied torque is 12 Nm. Determine the followings-

a) Shaft power

b) Volumetric efficiency

c) Overall efficiency

Soln.

Example 2

The pump is operating at a speed of 410 rpm and the pressure difference over the hydraulic pump is 82 bar. The nominal displacement is 5.2 cm3/rev. The overall efficiency is 83% and the volumetric efficiency

Is 91% calculate the followings-

a) Theoretical flow rate

b) Actual flow rate

c) Fluid power

d) Shaft power

e) Torque transmitted

Soln.

Given

N = 410 rpm

= 410/60 rps

= 6.83 rps

Theoretical flow rate Qt = Nominal displacement x speed

= 5.2 x 6.83

= 35.51 cm3/s

= 35.51x10-6m3/s

Volumetric efficiency \[\eta \]vol = \[\frac{{{\text{Qa}}}}{{{\text{Qt}}}}\] x 100

Qa = Qt x\[\eta \]vol /100

= 35.51x10-6x91/100

= 32.3 x 10-6 m3/s

Now fluid power Pf = Qa x Δp

Qa = 32.3 x 10-6 m3/s

Δp = 82 N/m2

= 82x105N/m2

Pf = 32.3x10-6x82 x105 watts

= 264.86 watts

Shaft power Ps = \[\frac{{2\pi N}}{{60}}\]

Overall efficiency \[\eta \]ova = \[\frac{{{\text{Pf}}}}{{{\text{Ps}}}}x100\]

Ps = Pf x 100/hova

= 264.86 x 100/83

= 319.1 watts

Ps = \[\frac{{2\pi x410x}}{{60}}\]

t = 319.1x60/ \[2\pi x410\] Nm

= 7.43 Nm