Site pages

Current course

Participants

General

Module 1: Formation of Gully and Ravine

Module 2: Hydrological Parameters Related to Soil ...

Module 3: Soil Erosion Processes and Estimation

Module 4: Vegetative and Structural Measures for E...

Keywords

Lesson 29 Control by Semi-permanent Structures

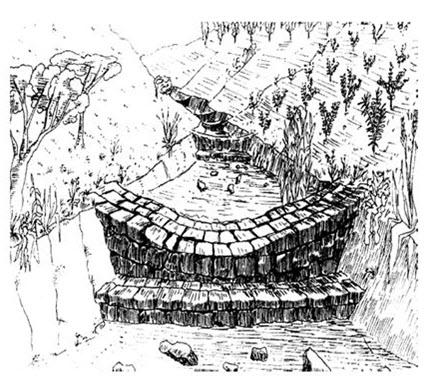

29.1 Loose Rock-fill Dam

This type of check dam is simple in construction and very effective for gully control. These dams are preferred in those areas, where plenty of loose rocks are available nearby the gully. The loose rock-fill dams are constructed with the help of stones. The stones are kept across gully width by wire netting made of fairly stout gauge of galvanized iron wire. The wire netting of about 2 meter or more in width is laid across the gully bed and over it the loose rocks are packed approximately up to half of the width of netting. The other half of netting is wrapped over the stones and laced to the other edge.

Fig. 29.1. Making of loose stones check dam. (Source: http://www.geoengineer.org/multimedia-virtual/item/282-history-of-rockfill-dam-construction-part-2)

Design and construction specifications of loose stone check-dam

The foundation of the dam is dug so that the length of the foundation will be more than the length of the spillway.

The width of the foundation depends upon the reservoir level height.

The dam should be properly keyed across its base and up the abutments to the crest elevation.

An adequate spillway should be provided for safe disposal of water.

An apron of non erodible material should be provided at the base, to dissipate the energy of water falling through the spillway.

Proper spacing between the successive dams should be ensured

The height of the dam should be properly planned

Stones should be placed such that they interlock easily and form a denser structure. If small stones are to be used they should be placed in the center and the outer surface covered with large stones to strengthen the dams.

Loose stone check-dams can be strengthened by covering the upstream wall and the crest with bamboo/reed-mat.

Fig. 29.2. A typical loose stone check-dam. (Source: http://opcgis.deq.state.ms.us/Erosion_Stormwater_Manual_2ndEd/Volume1/Chap_4_Sections/4_4/V1_Chap4_4_Runoff_Conveyance_CD.pdf)

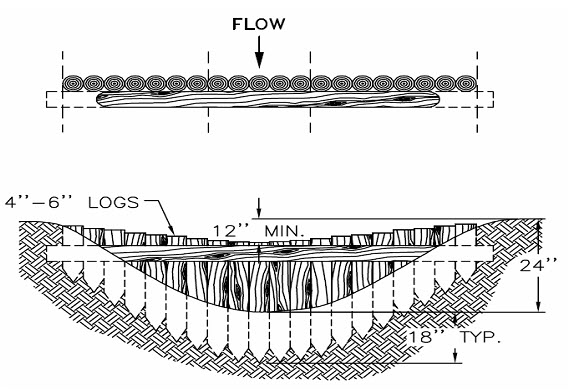

29.2 Log Check-dam

When large size timbers are readily available in the nearby area of gully, the log check dams are used for checking the gully. In this dam, the logs are used as brushwood but they make the structures substantially stronger. In the log check dam, two rows of vertical wooden posts are formed by inserting the wooden posts in line with the gully bed and extending up to the sides above the flood level and then logs are packed between the two rows. The vertical posts should be at least 10 cm in diameter and 2 m long. The spacing should be kept about one meter between each row, with the two rows of posts half meter apart. In wide and shallow gullies, it is better to keep all vertical post to a height of 60 cm above the ground surface so that the top of the dam can follow the section of stream bed. If the gully has steep sides, it should have a rectangular notch in the centre but the notch must be large enough to pass whole of runoff. The vertical posts on either sides of notch are responsible for dissipating the kinetic energy of flowing water. Therefore logs should not be swept down by the flow, for which stout posts must be driven to a greater depth than the others.

When the logs are fully packed between the rows of posts, the bottom layer to be sunk below the dam may be checked.

Fig. 29.3. Log Check Dam. (Source: http://opcgis.deq.state.ms.us/Erosion_Stormwater_Manual_2ndEd/Volume1/Chap_4_Sections/4_4/V1_Chap4_4_Runoff_Conveyance_CD.pdf)

29.3 Netting Dam

In this dam wire netting is used to form a small check dam. The netting dams are usually located near the top end of the gullies. This dam consists of wooden posts which are driven into the gully bed to support a strip of wire netting and thus, forming a low wall across the gully. The height of dam is kept about 60 cm. The lower edge of the netting is buried into the gully bed. The brush or straw is also piled loosely towards upstream side of the netting wall to form a barrier, which is porous in nature. But it slows down the flow velocity and results in deposition of sediment on the upstream side.

29.4 Geo-Textiles for Gully/Erosion Control

Geotextiles are porous fabrics known in the construction industry as filter fabrics, road rugs, synthetic fabrics, construction fabrics, or simply fabrics. Geotextiles are manufactured by weaving or bonding fibers made from synthetic materials such as polypropelene, polyester, polyethylene, nylon, polyvinyl chloride, glass and various mixtures of these. The uses of geotextiles include separators, reinforcement, filtration and drainage, and erosion control.

Geotextiles can be used for erosion control by using it alone. Geotextiles, when used alone, can be used as matting. Matting's are used to stabilize the flow on channels and swales. Also, matting is used on recently planted slopes to protect seedlings until they become established. Also, matting may be used on tidal or stream banks where moving water is likely to wash out new plantings.

Geotextiles are also used as separators. An example of such a use is geotextile as a separator between riprap and soil. This "sandwiching" prevents the soil from being eroded from beneath the riprap and maintaining the riprap's base.

Fig. 29.4. Mulch geotextiles. (Source: http://coirgreen.wordpress.com/2013/04/03/coirgreen-geotextiles-an-effective-soil-erosion-prevention-method/)

29.5 Sandbag Check-Dam

Sandbag check-dams are made from used jute or polyethylene bags (50 kg) filled with soil/sand. The bags are piled up to a maximum of 3 – 4 layers to form a small check-dam. This cheap technique is particularly useful in areas with insufficient supply of stones for building ordinary check-dams. By erecting sandbag dams large rills or small gullies (finger gullies) can be controlled, while they are not suitable for the treatment of large gullies.

Fig. 29.5. Sandbag check-dam. (Source: http://www.aquadam.net/Construction/Apple%20Creek-CA%20Dam/apple2.html)

29.6 Gravel-filled Burlap Bags

Gravel-filled burlap bags may be used for temporary check dams in areas of concentrated flow. The burlap bag flaps under the bags is folded in a direction away from the water flow. Gravel bag check dams are constructed such that the crest of the downstream check dam is approximately level with the toe of the upstream check dam. The check dams are installed so that the side end points are higher than the centerline crest. Erosion caused by high flows around the edges should be corrected immediately.

29.7 Retaining Wall with Bamboo-Mat

In gully rehabilitation scheme, the difficult part is to control the lateral flows which are coming from farm fields, footpaths, degraded grazing areas and other miscellaneous land use types. To protect the lateral flows and hence mass movement and soil sliding/melting from fragile sidewalls of a gully, retaining walls made out of reed/bamboo mat can be installed along the foot of the sidewall. The mat can be strengthened on the lower side by wooden sticks, possibly using vegetative propagating species like popular, willow and indigenous species. "Mini" bundles, with or without pegging, are also employed in small soil and moisture pockets. Arundo donax and Hyparrhenia stems consisting of three to four nodes each proved particularly useful for this purpose. Retaining, bundling and pegging commence with the onset of the rainy season.

Fig. 29.6. Protecting gully sidewall using bamboo-mat retaining wall. (Source: http://www.bebuffered.com/downloads/ManualonGullyTreatment_TOTFinal_ENTRO_TBIWRDP.pdf)

29.8 Precast Concrete Stacked Blocks Check-Dam

Stacked precast concrete blocks can also be used for the construction of check dam structures. Some requirements for precast concrete block check dams are:-

i) Proper foundation has to be provided to prevent excessive deformation and bearing capacity failure. If necessary the layer of soft and peat soils should be replaced.

ii) The stacked precast concrete blocks should be stable and designed as mass gravity wall that is able to resist both hydraulic and earth pressures.

iii) The dimensions of each individual precast block are to be decided based on handling as well as stability requirements

iv) The precast blocks should be able to be removed swiftly in case of overtopping and flooding problems.

a) Side View

a) Upstream View

Fig. 29.7 Precast Concrete Stacked Blocks Check Dam Structures. (Source: http://info.water.gov.my/attachments/article/324/GuidelineCheckDamsCompleteSet.pdf)

29.9 Locally Available "Organic" Gabion Boxes

“Organic” gabion boxes are made from locally available bamboo and reed strips, which are woven and tied together to form cubic, permeable boxes to be filled with stone. The organic gabions are placed across gully floors, and buttressed downstream for stability. The characteristic of the specific location determines the height and the width of the organic gabion check-dam, and consequently the number and size of gabions to be utilized for. Consequently, the velocity of the run-off is reduced, and sedimentation creates a favorable atmosphere/ environment for the establishment of permanent biological structures. Accordingly, appropriate vegetative structures are put in place so as to strengthen and finally replace the "organic" gabion that rots over time.

Fig. 29.8. Check-dams constructed out of organic boxes (bamboo and reed mat). (Source: http://www.bebuffered.com/downloads/ManualonGullyTreatment_TOTFinal_ENTRO_TBIWRDP.pdf)

29.10 Silt Fence

A silt fence is a temporary sediment barrier consisting of fabric stretched across and attached to supporting posts and entrenched into the soil. It is generally installed perpendicular to the flow direction to slow down or stop water and to allow filter/perimeter protection, settling of soil particles, and/or reduce water velocity/erosive forces.

Fig. 29.9. Silt Fence. (Source: http://www.interstatelandscaping.com/Page_4.html)

29.11 Sediment Basin

Semi-permanent to permanent version of the Sediment Trap is constructed by excavation, embankment, or a combination of these to intercept, trap, and retain sediment from runoff while allowing detained runoff to slowly drain, infiltrate, or both. These structures are used for indefinite periods of sediment collection associated with long term disturbance of the earth such as mining, farming, unpaved road drainage, etc. Sediment and runoff storage capacities are often larger than sediment traps, and embankments are usually constructed from more permanent materials such as compacted earth, rock, concrete, etc. Sediment laden runoff can be drained and filtered by perforated pipe, rock filtration, rock dam seepage, infiltration, pumping, or a combination of these.

Fig. 29.10. Sediment Basin. (Source: http://www.al.nrcs.usda.gov/news/sstories/1109sed_basin_lee.html)