Site pages

Current course

Participants

General

Module 1: Fundamentals of Reservoir and Farm Ponds

Module 2: Basic Design Aspect of Reservoir and Far...

Module 3: Seepage and Stability Analysis of Reserv...

Module 4: Construction of Reservoir and Farm Ponds

Module 5: Economic Analysis of Farm Pond and Reser...

Module 6: Miscellaneous Aspects on Reservoir and F...

Lesson 6 Earthen Embankment Classification

6.1 Introduction

Earthen dams and earthen levees are the most ancient type of embankments, as they can be built with the natural materials with a minimum of processing and primitive equipment. But in ancient days, the cost of carriage and laying of the dam materials was very low. The cost of gravity dams on the other hand has gone up because of an increase in the cost of concrete, masonry etc. Earthen dams are still cheaper as they can utilize the locally available materials and less skilled labour is required for them.

Gravity dams and arch dams require sound rock foundations, but earthen dams can be easily constructed on earth foundations. However earth dams are more susceptible to failure as compared to rigid gravity dams or arch dams. Before the development of the subject of soil-mechanics, the earth dams were being designed and constructed on the basis of experience, as no rational basis for their design was available. This led to the failure of various earthen embankments. However, now-a-day these dams can be designed with a fair degree of theoretical accuracy provided the properties of the soil placed in the dam are properly maintained. This condition makes the design and construction of such dams, thoroughly interdependent. Continuous field observations of deformations and pore water pressures have to be made during the construction of such dams. Suitable modifications in the design are then made during construction depending upon these field observations.

The earthen dam can be classified according to method of construction as follows:

Hydraulic-fill dam

Rolled-fill dam

6.2 Hydraulic-fill Method

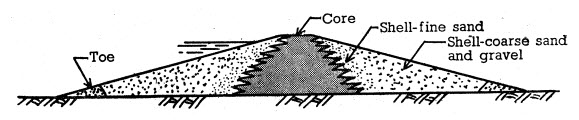

A hydraulic fill dam is one in which the material is transported in suspension in water to the embankment where it gets placed by sedimentation (Fig. 6.1). Pipes called flumes are laid along the outer edge of the embankment. The soil materials are mixed with water and pumped into these flumes. The slush is discharged through the outlets in the flumes at suitable intervals along their lengths. The sorting effect of flowing water is utilised in creating a fine-grained core at the centre of the embankment and the coarse shells on the sides. The slush flowing towards the centre of the bank tends to settle down. The coarser particles get deposited soon after the discharge near the outer edge, while the fines get carried and settle at the centre, forming a zoned embankment having a relatively impervious central core. In a semi-hydraulic fill dam the material is transported by hauling units and dumped at the edge of the embankment. It is then washed to its final position by water jets. Since the fill is saturated when placed, high pore pressures develop in the core material, and the stability of the dam must be checked for these pressures. This type of embankment is susceptible to settlement over long periods, because of slow drainage from the core. The use of this type of dam is rare, because;

The cost of rolled earth has dropped rapidly with the development of larger more economical earth moving equipment.

It is difficult to control the quality which makes them less dependable than other types of dam.

Hydraulic-fill method is therefore, seldom adopted these days. Rolled-fill method for constructing earthen dam is generally and universally adopted in these modern days.

Fig. 6.1. Cross sectional view of Earth-fill dam.

6.3 Rolled-fill Method

The embankment is constructed by placing suitable soil materials in thin layers and compacting them with rollers. The soil is brought to the site from burrow pits and spread by bulldozers etc. in layers. These layers are thoroughly compacted by rollers of designed weights. Ordinary road rollers can be used for low embankments (such as for levees or bunds); while power-operated rollers are to be used for dams. The moisture content of the soil fill must be properly controlled. The best compaction can be obtained at or near the optimum moisture content (the moisture required for obtaining optimum density in the fill). Compaction of coarse gravels cannot be properly done by rolling and is best done by vibrating equipments.

Rolled filled dams are further classified as:

Homogenous Embankment

Zoned Embankment

Diaphragm type.

6.3.1 Homogenous Embankment

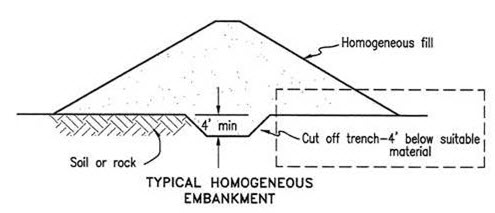

The simplest type of an earthen embankment consists of a single material and is homogenous throughout (Fig. 6.2). Sometimes a blanket of relatively impervious material may be placed on the upstream face. A purely homogenous section is used, when only one type of material is economically or locally available. Such a section is used for low to moderately high dams and for levees. Large dams are seldom designed as homogenous embankments.

Fig. 6.2. Homogeneous type embankments. (Source: htpp://vwrrc.vt.edu)

A purely homogenous section poses the problems of seepage, and so, huge sections are required to make it safe against piping, stability, etc. Due to this a homogenous section is generally added with an internal drainage system such as a horizontal drainage filter or rock toe, etc. The internal drainage system keeps the phreatic line well within the body and steeper side slopes of the dam and thus, smaller sections can be used. The internal drainage is therefore always provided in almost all types of embankments.

6.3.2 Modified Homogeneous Embankment

Although earlier homogeneous embankments were very common in the design of small dams, the purely homogenous section has been modified in recent designs. In this modified homogeneous sections, a small amount of carefully placed pervious materials control the action of seepage so as to permit much steeper slopes. Modification of homogenous type section by means of drainage furnishes a greatly improved design. Completely homogeneous section should not be used for storage dams. Drainage should always be provided when a reservoir pool will be maintained for an appreciable length of time. A homogenous (or modified homogenous) type dam is applicable in areas where readily available soil shows little variation in permeability.

Rock toes of appreciable size may be provided for drainage. In case of availability of suitably graded materials, a horizontal drainage blanket may be used. Another method of providing drainage is accomplished through installation of pipe drains. These are recommended for small dams in conjunction with horizontal drainage blanket in pervious zones. Pipe drains are not entirely reliable due to the possibility of clogging. Improper filters, root growth, or deterioration of the system components may be the reasons for such clogging of the drain pipes.

6.3.3 Zoned Embankment

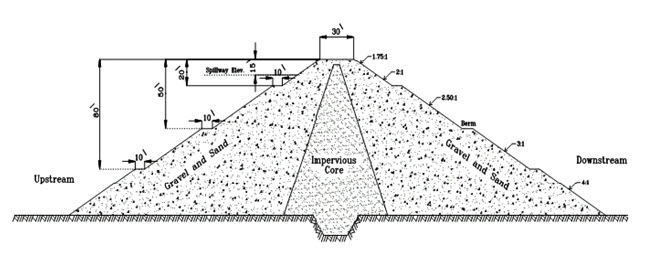

Zoned embankments are usually provided with three zones such as central, transition and outer zone. While the central impervious core is surrounded by a comparatively previous transition zone, the latter is covered with a much more previous outer zone (Fig. 6.3). The central core checks the seepage. The transition zone prevents piping through cracks which may develop in the core. The outer zone gives stability to the central impervious fill and also distributes the load over a large area of the foundation. These types of embankments are widely constructed and the materials of the zones are selected depending upon their availabilities.

Clay although highly impervious in nature may not be a good material for the best core because it shrinks and swells too much under dry and wet conditions, respectively. Due to this reason, the clay is sometimes mixed with fine sand or fine gravel in order to become the most suitable material for the central impervious core. Silts or silty-clay soil may be used as a satisfactory central core material. Freely draining materials such as coarse sands and gravels are used in the outer shell. Transition filters are recommended when there is an abrupt change of permeability of the material in between two contiguous zones. So, the transition filter is provided between the inner and the outer zone of the zoned embankment.

Fig. 6.3. Different forms of Zoned embankments. (Source: htpp://vwrrc.vt.edu)

6.3.4 Diaphragm Type Embankment

Diaphragm type embankments have a thin impervious core, which is surrounded by earth or rock fill as shown in Fig. 6.4. The impervious core is also called as diaphragm and it is made of impervious soils, concrete, steel, timber etc. It acts as a water barrier to prevent seepage through the dam. The diaphragm may be placed either at the central vertical core or at the upstream face as a blanket. In order to avoid excessive under-seepage through the existing previous foundations, the diaphragm may be tied to the bed rock or to a very impervious foundation material.

Fig. 6.4. Diaphragm type embankment. (Source: http://osp.mans.edu.eg)

The diaphragm type of embankment is differentiated from zoned embankment by the thickness of the core. When the thickness of the diaphragm at any elevation is less than 10 meters or less than the height of the embankment, the dam embankment is considered to be a diaphragm type. In case, the thickness of the diaphragm equals or exceeds these limits, it is considered to be a zoned embankment.

Keywords: Earthen dam, Zones, Seepage, Diaphragm

Suggested Readings

Garg, S. K. (2011). Irrigation Engineering and Hydraulic Structures. Khanna Publishers.

http://vwrrc.vt.edu/swc/july2009updates/IntroductionAppAEarthenEmbankmentsSCraftonRev30Jun09.html