Site pages

Current course

Participants

General

MODULE 1. Orhtographic Projections of Machine comp...

MODULE 2. Types of joints

MODULE 3. Computer Aided drawing

MODULE 4. Numeric control systems

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

LESSON 6. Types of rivet heads and riveted joints, process of producing leak proof joints

6.1.Introduction

When two plates or parts are joined together, they may joined permanently or temporarily. Thus the joints may be classified as

-

Permanent joints or fastenings, and

-

Temporary joints or fastenings.

Permanent fastenings

These are joints which cannot be disassembled without breaking the connecting or joining components. Welded joints, riveted joints are permanent joints.

Temporary fastenings

These joints are made temporarily so that they can be disassembled when ever required without destroying the connecting or joining components. Screwed joints and pin joints are temporary joints.

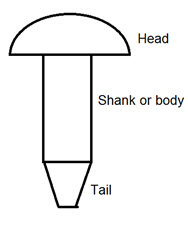

6.1.1.Rivet

The rivet is a piece of metal usually, mild steel or wrought iron used to make permanent joints that has strength and tightness. It is also made of brass, aluminium and copper.

Fig.6.1

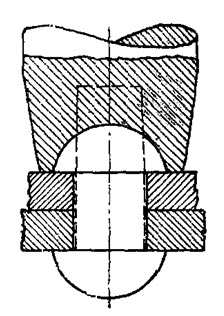

6.1.1.1.Riveting: The process of forming another rivet-head, after the rivet is placed in the holes previously drilled or punched through the plates, is called riveting

Fig.6.2.Riveting

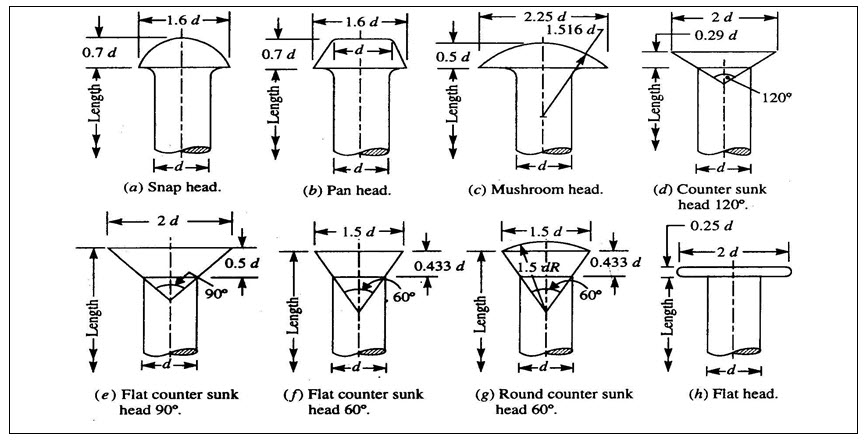

6.1.2.Types of rivet Heads

The rivet heads are classified in to three types according to the Indian standard specifications:

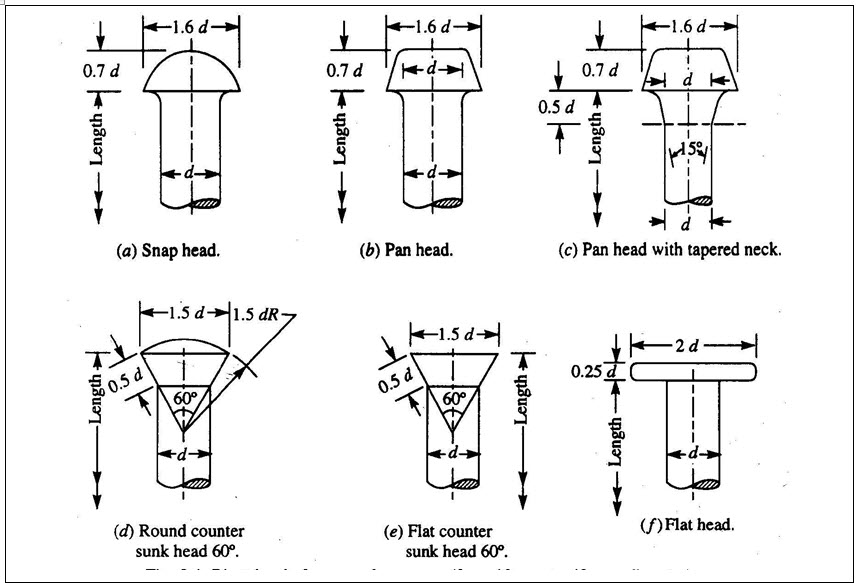

1.Rivet heads for general purposes (below 12mm diameter) according to IS: 2155-1982 (Reaffirmed 1996)

Fig.6.3.Rivet heads for general purposes (below 12mm diameter)

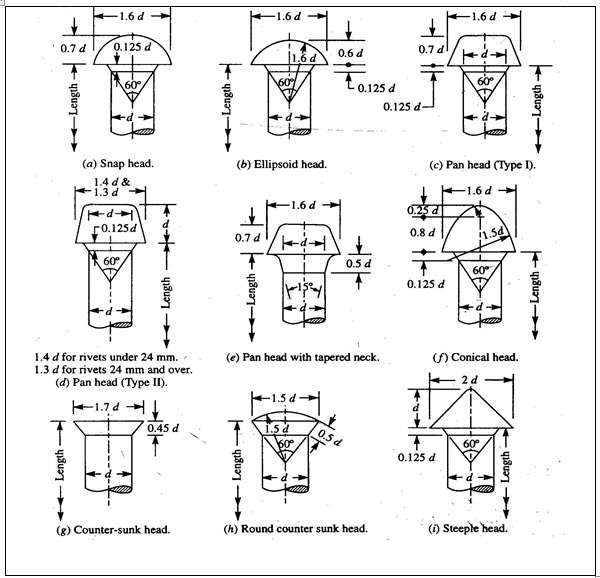

2.Rivet heads for general purposes (from 12mm to 48mm diameter) according to IS: 1929-1982 (Reaffirmed 1996)

Fig.6.4.Rivet heads for general purposes (from 12mm to 48mm diameter)

3.Rivet heads for boiler work (from 12mm to 48mm diameter) according to IS: 1928-1961 (Reaffirmed 1996)

Fig.6.5.Rivet heads for boiler work (from 12mm to 48mm diameter)

For machine riveting and structural work, snap heads are used.

For ship building, counter sunk heads are used.

For hand hammering, conical heads are used.

6.1.3.Types of riveted Joints

The riveted joints are used in ship-building and for the construction of steel buildings, bridges, boilers, tanks etc., There are two types of riveted joints depending on the way in which the plates are joined.

- Lap joint and 2. Butt joint

6.1.3.1.Lap joint

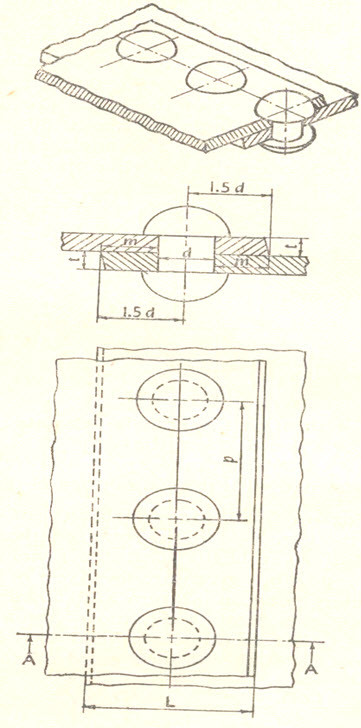

A lap joint is a joint in which one plate is kept over the other and then the two plates are riveted together.

When the joint is made with only one row of rivets, it is called a single-riveted lap joint.

The sectional front view and top view of a single-riveted lap joint are shown in the fig.6.6. The width of overlap L is equal to 3d.

Fig.6.6. Single riveted Lap joint

When the joint is made with only two rows of rivets, it is called a Double-riveted lap joint.

When the joint is made with only three rows of rivets, it is called a Triple-riveted lap joint.

TABLE – 1

|

Thickness of plate, t mm |

8 |

9 |

10 |

11 |

12 |

14 |

16 |

18 |

20 |

22 |

25 |

|

Diameter of rivet, d mm |

17 |

18 |

19 |

20 |

21 |

22 |

24 |

26 |

27 |

28 |

30 |

When two or more rows of rivets are used, rivets may be arranged in (i) chain or (ii) zigzag formation.

The distance between the rows of rivets, called the row pitch Pr, should not be less than 0.6p for zigzag riveting, and 0.8p for chain riveting. In terms of d, the approximate values of pr are 2d and 2d + 6 mm respectively. In zigzag arrangement, the distance between the centre of a rivet in one row and the centre of the nearest rivet in the adjoining row, is called the diagonal pitch.

This pitch is also often considered instead of the row pitch and its value is obtained by the formula,

6.1.4.2.Butt joint

6.1.4.2.Butt joint

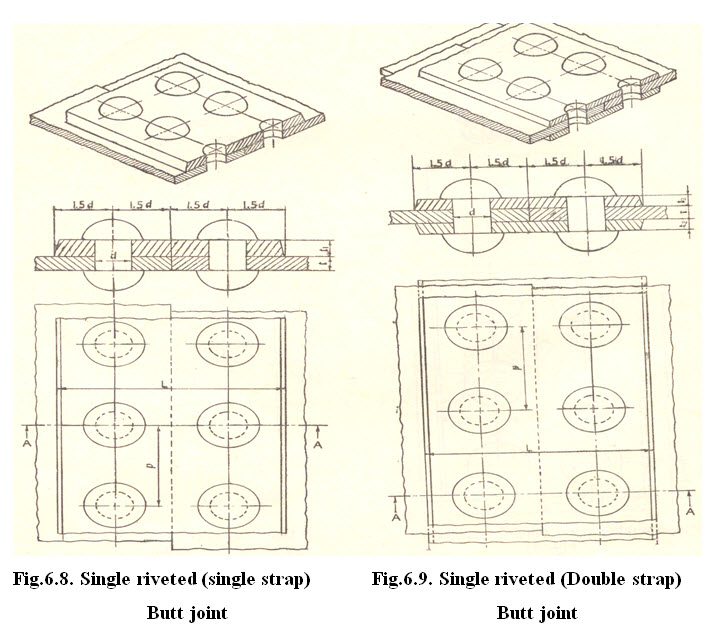

A butt joint is a joint in which the two plates to be connected are kept in alignment butting (touching) each other and a cover plate is placed on one side or on both the sides of the two main plates to be joined . The cover plate(s) are then riveted to the main plates. . At least two rows of rivets, one in each connected plate, are necessary to make the joint. The butt joints may be single strap butt joint or double strap butt joints.

Thickness of butt-strap: When only one strap is used, thickness t1 = t to 1.125t; when two straps are used, thickness t2 = 0.7t to 0.8t, where t is the thickness of the plates to be connected.

.

.

Similarly, double riveted single strap butt joint, double riveted double strap butt joint, double riveted (chain) single strap butt joint, double riveted(zigzag) single strap butt joint etc., are also made based on the requirement.

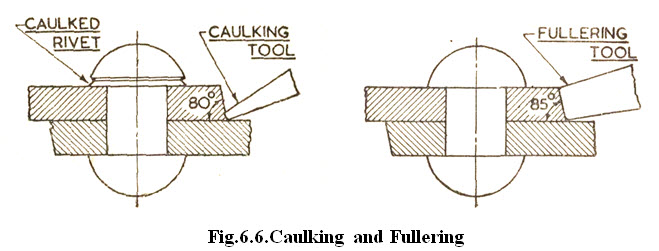

6.1.4. Process of producing leak proof joints

The riveted joints are used to produce leak proof joints in case of boilers and ship building works. These joints are made by the processes namely caulking and fullering. The edges of the plates are hammered and driven-in by a caulking tool (fig. 6.6) or a fullering tool (fig. 6.6). The caulking tool is in the shape of a blunt chisel. Leakage through the hole is prevented by the caulking operation on the edge of the rivet-head The thickness of the fullering tool is about the same as that of the plates. To facilitate these operations the edges of the plates are usually machined to an angle of about 80° before joining them together. This angle is increased to about 85° after the fullering process.