Site pages

Current course

Participants

General

MODULE 1. Orhtographic Projections of Machine comp...

MODULE 2. Types of joints

MODULE 3. Computer Aided drawing

MODULE 4. Numeric control systems

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

LESSON 7. Threads nomenclature, profiles, multi start, left and right hand and conventional representation of threads

7.1. Introduction

The temporary joints are made by means of bolts and nuts, keys and pins. The screwed fastenings are more advantageous and reliable. The bolts and nuts are having different types of threads. The threads are used based on the type of application of the screwed joints. A screw thread is formed by cutting helical groove on a cylindrical rod. If the helical groove cut is single, then the thread is known as single threaded and if a second groove is cut in between the first groove, a double threaded screw is formed. The helical groove may be right hand or left hand and the thread is known as right hand thread and left hand thread.

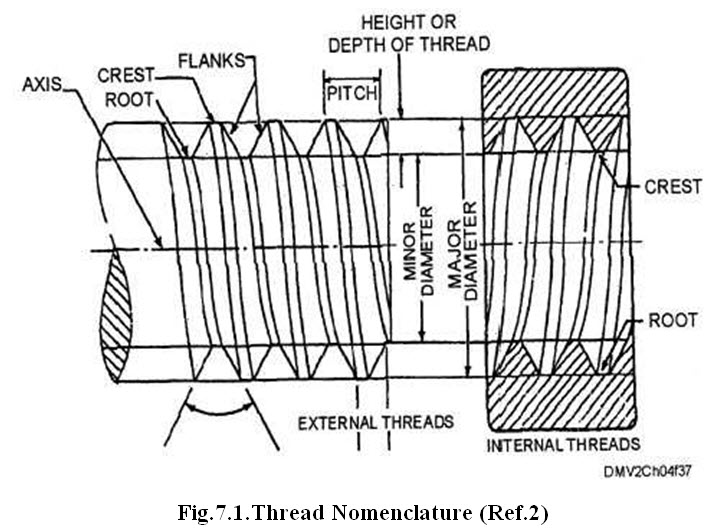

7.1.2.Thread nomenclature

1.Major diameter :Largest diameter of an external or internal screw thread.

2. Minor diameter : Smallest diameter of an external or internal screw thread.

3.Pitch diameter : The diameter of an imaginary cylinder passing through the thread at such points as to make the width of the thread and the width of the spaces between the thread are equal.

4.Pitch : The distance from one point on one thread to the corresponding point on the next thread.

5.Lead : The distance advanced by a screw thread axially in one rotation of the nut.

6. Crest : The top surface of the thread.

7. Root : Bottom part in between the two threads.

8.Depth of thread : Perpendicular distance between the crest and root.

9. Flank : surface joining the crest and root.

10. Angle of thread : Angle between the flanks of the thread.

11. External thread : A thread on the external surface of the cylinder.

12. Internal thread : A thread on the internal surface of the cylinder.

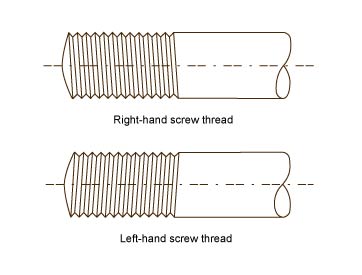

13.Right –hand thread : A thread when viewed axially, winds in a clockwise direction. Normally all the threads are right hand threads except for some specific needs.

14. Left-hand thread : A thread when viewed axially, winds in a anti-clockwise direction. Left hand threads are designated LH.

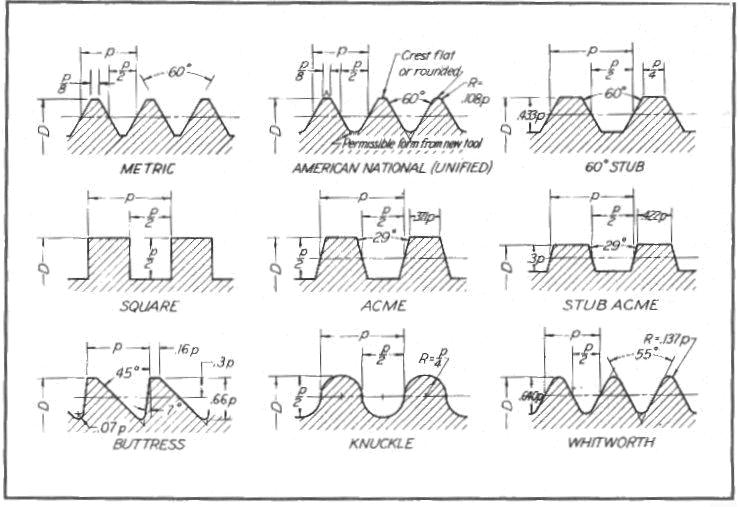

7.2.Screw thread Profiles

Fig.7.2. Screw thread profiles

Metric thread : It is an Indian standard thread with an included angle of 60°

Unified thread : It is a common screw thread system for Great Britain, Canada and United states with an included angle of 60°

Square thread : square threads have high efficiency and are used for transmission of power in either directions.

Acme thread : It is a modification of square thread. These are much stronger than square thread.

Buttress thread : It is used for transmission of power in one direction only.

Knuckle thread : This also a modification of square thread. These are used for easy engagement.

Whitworth thread : These are having symmetrical V thread with an included angle of 55°

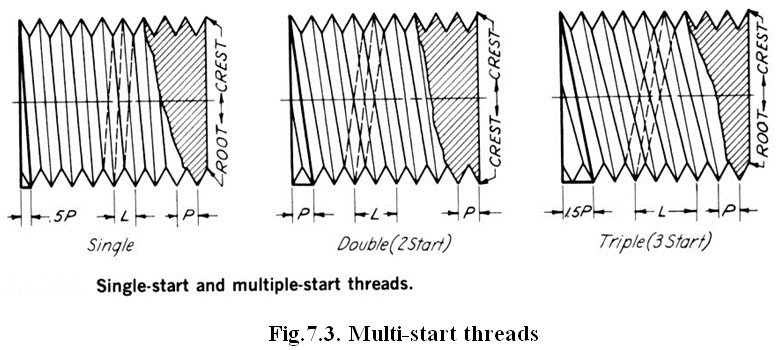

7.3. Multi-start thread

Normally threads will be single start and because this the core diameter will be small and the strength of the fastener will be less. To avoid this multi start threads are used. In multi start threads, the lead may be increased by increasing the number of starts without increasing the pitch. They are also used in fasteners where quick action is required like fountain pen, hydraulic valves etc.,

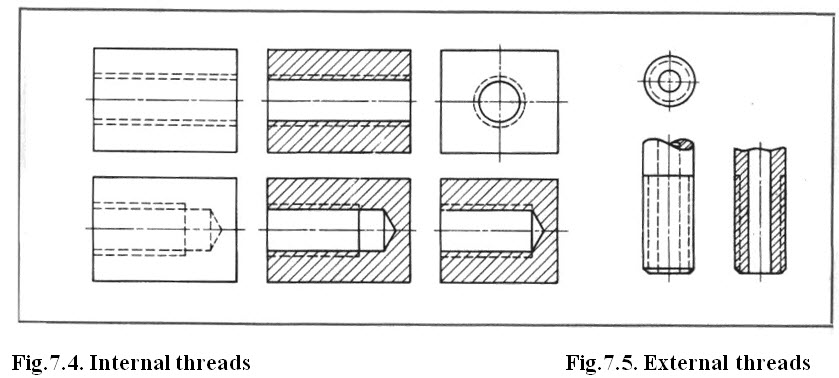

7.3. Conventional representation of threads

Fig.7.6. Right hand threads and Left hand threads