Site pages

Current course

Participants

General

MODULE 1. Orhtographic Projections of Machine comp...

MODULE 2. Types of joints

MODULE 3. Computer Aided drawing

MODULE 4. Numeric control systems

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

LESSON 8. Nuts and bolts- square headed, hexagonal, types of lock nuts, studs, machine screws, cap screw and wood screw, foundation bolts

8.1.Introduction

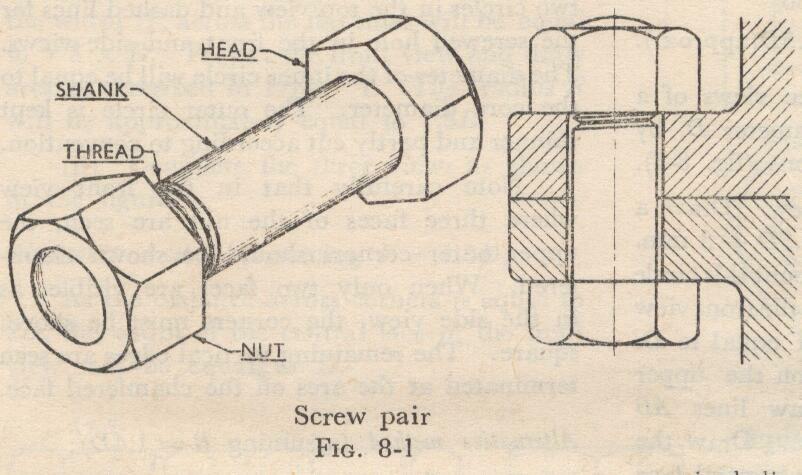

The bolt and nut joint or screwed fastening is a temporary joint. A bolt is used to join two assembled parts with the help of a mating part, the nut. A screw is used to join two parts by making its own thread in the joining part while screwing itself. We have different types of bolts and nuts classified based on the type of thread and also based on the type of application.

8.2. Nuts and bolts

A nut is an internally threaded component joined to the externally threaded bolt.

A nut and a screw or a bolt comprise what is known as a screw pair.

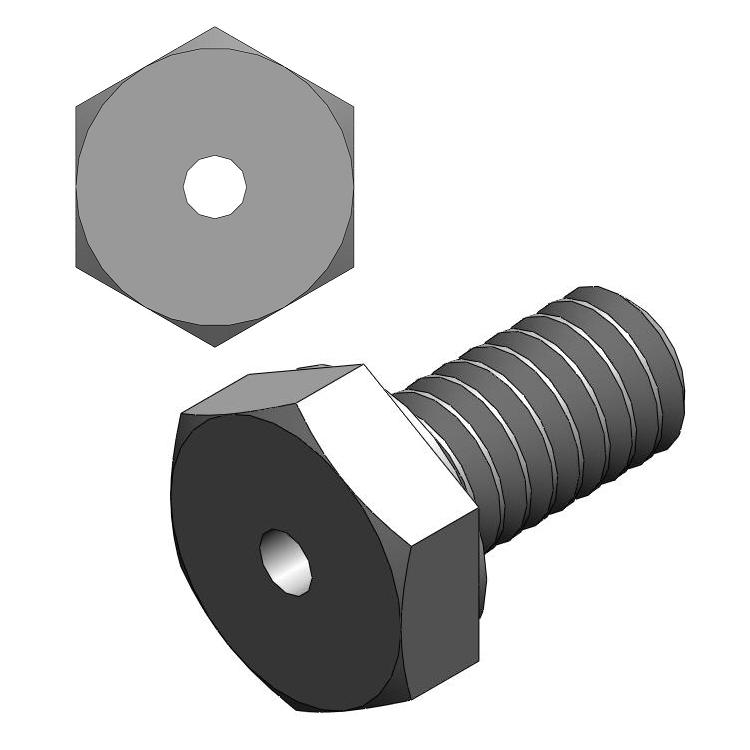

Fig.8.1. Bolts and Nuts

8.2.1.Nuts

Nuts are generally in the form of hexagonal or square prisms. Other forms are also used to suit specific requirements.

Hexagonal nuts are generally used in most of the applications. The spanner used for turning the nut can have better hold on a square nut than on a hexagonal nut, but the angle through which the spanner will have to be turned to get another hold is only 60° in case of a hexagonal shape, while it is 90° in case of a square shape. Hence, it is more convenient to screw-on a hexagonal nut than a square nut. An octagonal nut would require only turn, but there would be greater tendency for the spanner to slip. Hence, this shape is seldom used. Nuts of forms other than the above two are usually provided with special facilities for screwing them on or off the bolts.

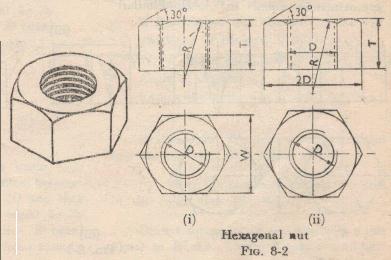

8.2.1.1.Hexagonal nut

The upper corners of this nut are rounded-off or chamfered. The chamfering is generally conical. The angle of chamfer is 30° or 45° with the base of the nut. Due to chamfering, an arc is formed on each vertical face, and a circle is formed on the top surface of the nut.

The dimensions of the hexagonal nut cannot be expressed exactly in terms of the nominal diameter of the bolt. The standard proportions for nuts and bolt-heads may be obtained from tables. For elementary work, the following approximately standard dimensions may be adopted

If D = the nominal diameter of the bolt,

Thickness of the nut, T = D

Width across flats, W = 1.5D + 3 mm

Angle of chamfer = 30°

Radius of chamfer arc, R = 1.4D (approx.)

Very often, and especially when a nut is shown in one view only, the following rough rule dimensions are used.

Thickness of the nut, T = D

Distance across diagonally

opposite corners = 2D

Angle of chamfer = 30°

Radius of chamfer arc, R = 1.5D(approx.).

Fig.8.2. Hexagonal Nut

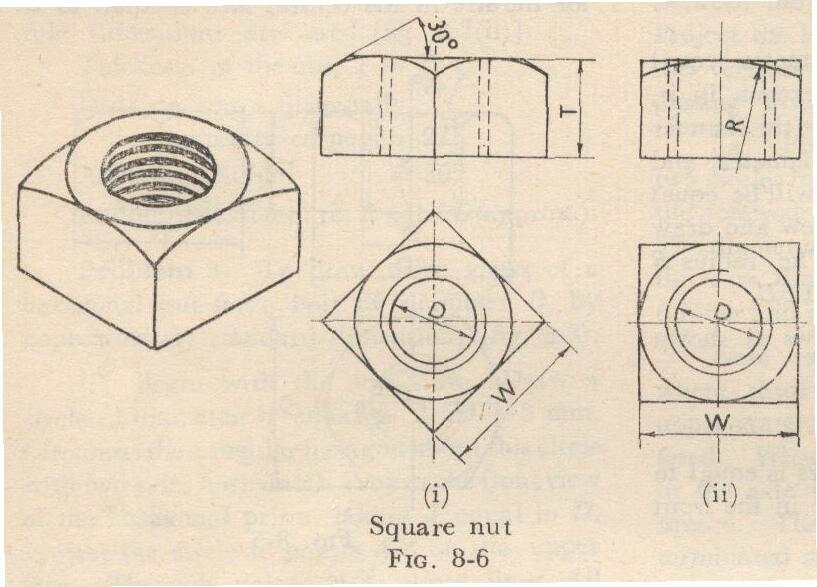

8.2.1.2.Square nut

The upper corners of the square nut are also chamfered in the same manner as those of the hexagonal nut. The widths across flats of a square nut and a hexagonal nut, for the same size of bolt, are also equal.

Dimensions of a square nut:

If D = the nominal diameter of the bolt,

Thickness of the nut, T = D

Width across flats, W = 1.5D + 3mm

Angle of chamfer = 30°

Radius of chamfer arc, R = 2D (approx.).

Fig.8.3. Square Nut

8.2.2. Bolts

A bolt comprises of two parts a shank and a head. The shank is cylindrical and is threaded at the tail end for a sufficient length so as to effectively engage with a nut. The shape of the head depends upon the purpose for which the bolt is required. While considering the length of the bolt, the thickness of the head is not taken into account.

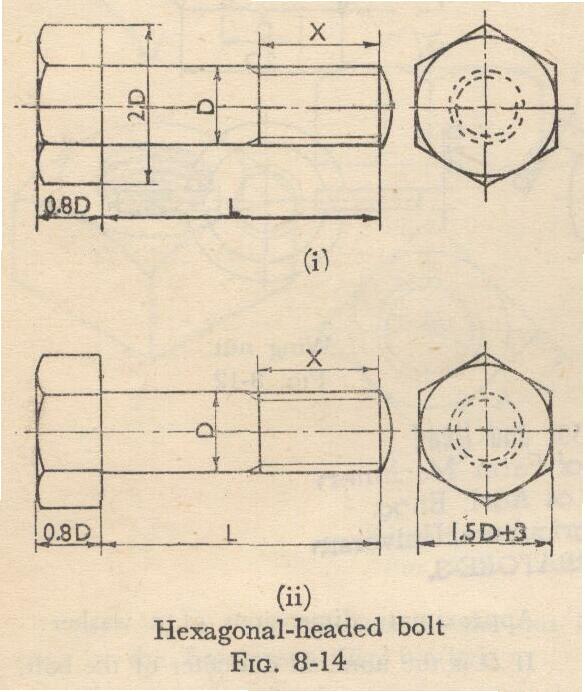

8.2.2.1.Hexagonal-headed bolt

This is the most common form of a bolt. The hexagonal head is chamfered at its upper end. To prevent rotation of the bolt while screwing the nut on or off it, the bolt-head is held by another spanner. The dimensions of the bolt-head are the same as those of the hexagonal nut, except for the thickness.

|

|

|

Fig.8.4. Hexagonal Bolt

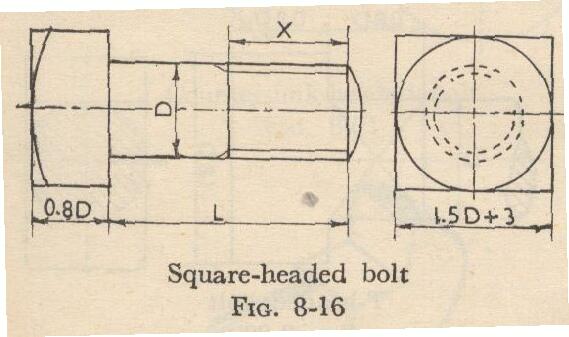

8.2.2.2.Square-headed bolt

This bolt is generally used when the head is to be accommodated in a recess. This recess also is made of square shape so that the bolt is prevented from turning when the nut is screwed on or off it. This bolt is commonly used in bearings for shafts. The bolt-head is chamfered as its upper end.

|

|

|

Fig.8.3. Square Bolt

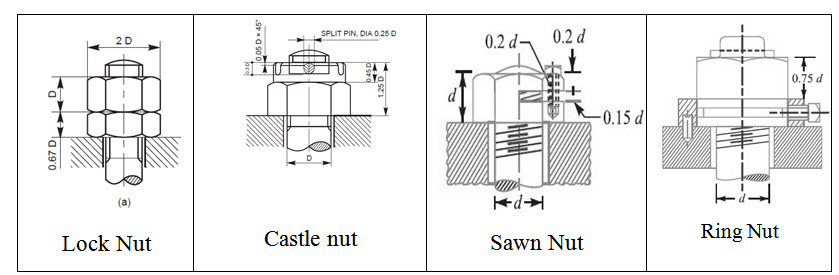

8.3. Types of lock nuts

In a bolted joint, the nut may become loose, due to vibration. This may loosen the joint itself. To avoid this, another nut is used to lock the original nut. The thickness of a lock nut is usually two-thirds D, where D is the major diameter of the bolt. The lock nut is usually placed below the standard nut. To make the joint, the lock nut is first screwed tightly and then the standard nut is tightened till it touches the lock nut. Afterwards, the locknut is then screwed back on the standard nut, which is held by a spanner. The threads of the two nuts become wedged between the threads of the bolt.

- Jam Nut or lock nut. This is about one half or two third thickness of standard nut.

Fig.8.4. Types of Lock Nuts

-

Castle nut. It is a hexagonal nut with cylindrical upper part. This part is slotted in line with the centre of each face. A split pin is inserted through two slots in the nut and a hole in the bolt. This used in automobile industry.

-

Sawn nut. It has a slot sawn half way through. After the nut is tightened, the small screw is screwed which produces more friction between the nut and the bolt preventing the loosening of the nut.

-

Penn, ring or grooved nut. It has a upper hexagonal part and a lower cylindrical part. The bottom cylindrical portion is recessed to receive the tip of locking set screw.

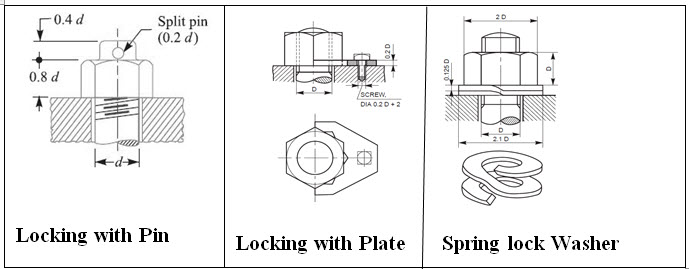

-

Locking with pin. The nuts are locked by means of taper pin or cotter pin.

-

Locking with plate. A plate or locking plate is used to lock the bolt.

-

Spring lock washer. As the nut is tightened, one edge of the washer will be digging itself in the that piece thus increasing the resistance so that the nut will not be loosened.

Fig.8.5. Types of Locking

8.4.Studs

The stud is a cylindrical shank threaded at both ends. The nut-end N is threaded for a length slightly more than the thickness of a nut or nuts to be used. The other end M, called the metal-end is threaded for a length at least equal to the diameter of the stud. The length of the plain part P, between the two ends, depends upon the thickness of the piece adjoining the nut. The stud is used in place of a bolt, when there is insufficient space to accommodate the bolt-head or to avoid use of an unnecessarily long bolt. Studs are commonly used to connect cylinder covers to engine cylinders.

Fig.8.6.Stud

Machine screws

Machine screws are uniformly threaded bolts having nominal diameter less than quarter inch and tightened by a nut, used to fasten various components together in machines, tools, etc.,

Fig.8.7.Machine screw

Cap screws

This is screw having a shank threaded throughout its length and is usually tightened in a tap made in the machine.

Fig.8.8.Cap screw

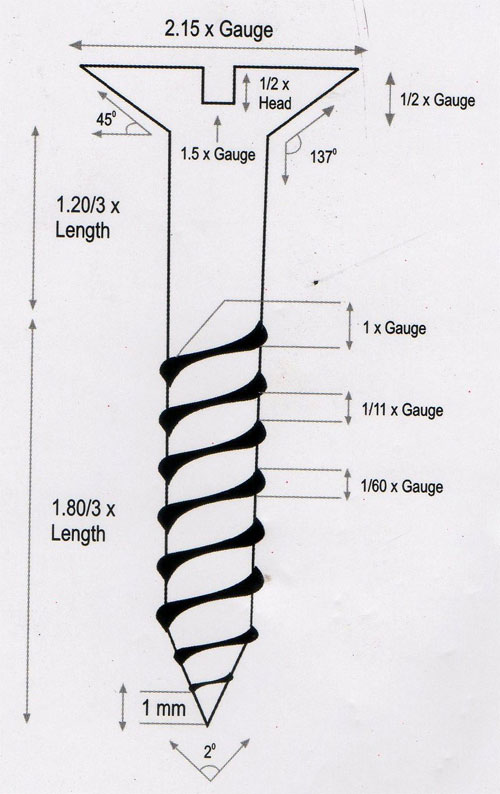

Wood screws

Any of the screw having slotted head so that it can be tightened by a screw driver in to wood is known as wood screw.

Fig.8.9.Cap screw

Foundation bolts

These bolts are made from mild steel or wrought iron rods for fixing heavy machines in the ground. The size of the bolt depends on he size of the machine. These bolts are placed in cement concrete so that they are permanently fixed in the ground.

Fig.8.10.Foundation bolt