Site pages

Current course

Participants

General

MODULE 1. Electro motive force, reluctance, laws o...

MODULE 2. Hysteresis and eddy current losses

MODULE 3. Transformer: principle of working, const...

MODULE 4. EMF equation, phase diagram on load, lea...

MODULE 5. Power and energy efficiency, open circui...

MODULE 6. Operation and performance of DC machine ...

MODULE 7. EMF and torque equations, armature react...

MODULE 8. DC motor characteristics, starting of sh...

MODULE 9. Polyphase systems, generation - three ph...

MODULE 10. Polyphase induction motor: construction...

MODULE 11. Phase diagram, effect of rotor resistan...

MODULE 12. Single phase induction motor: double fi...

MODULE 13. Disadvantage of low power factor and po...

MODULE 14. Various methods of single and three pha...

LESSON 19. DC series motor characteristics

The Series Motor.

In the series motor the field is connected in series with the armature, as shown in figure 8.9.

Fig. 8.9 Series motor

The field has comparatively few turns of wire and this wire must be of sufficient cross-section to carry the rated armature current of the motor. In the series motor the flux, φ depends entirely on the armature current. If the iron of motor is operated at moderate saturation, the flux will be almost directly proportional to the armature current. Therefore, in the expression for torque,

T = Kt I φ , if φ is assumed to be proportional to I,

the expression becomes

T = K't I2 where K't is a constant.

The torque is proportional to the square of the armature current, as shown in figure below. The doubling of the armature current results in the quadrupling of the torque. It will be noted that as the current increases above 60 A, the torque rises very rapidly. This characteristic of the series motor makes its use desirable where large increases of torque are desired with moderate increases in current. In practice, saturation and armature reaction both tend to prevent the torque increasing as rapidly as the square of the current. When speed equation already seen for shunt motor, is applied to the series motor, the speed

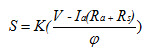

where K is a constant, V the terminal voltage, Ia the motor curtrent, Ra the armature resistance including brushes, Rs the series field resistance and φ the flux entering the armature from a north pole. Rs the resistance of the series field, is now added to the armature resistance in order to obtain the total motor resistance. Both Ia and φ vary with the load.

As the load increases, the voltage drop in the field resistance and the armature resistance increases because this voltage drop is proportional to the current. Therefore, the back emf. becomes less, which causes the motor to run more slowly, although this effect is only of the magnitude of a few per cent. The flux φ, however, increases almost directly with the load. Therefore the speed must drop, such that the back emf is less than the terminal voltage. Both effects tend to slow down the motor. The resistance drop is ordinarily from 2 to 6 per cent, of the terminal voltage V, so its effect on the speed is only of this magnitude. The speed is, however, inversely proportional to the flux φ and a given percentage change in φ produces the same percentage change in the speed.

When the load is decreased, the flux φ correspondingly decreases and the armature must speed up in order to develop the required back emf. If the load be removed altogether, φ becomes extremely small, resulting in a very high speed. It is dangerous to remove the load from series motors, as their armatures are almost certain to reach speeds where centrifugal action will wreck them.

Figure 8.10 shows the characteristic curves of a series motor plotted with current as abscissas. The torque curve concaves upward for the reasons which have just been stated. The speed is inversely proportional to the current. The characteristics cannot be determined for small values of current because the speed becomes dangerously high. The efficiency increases rapidly at first, reaches a maximum at about half load and then decreases. This is due to the fact that at light loads the friction and iron losses are large as compared with the load. The effect of these becomes less as the load increases. The field and armature loss varies as the square of the current , so these losses increase rapidly with the load. The maximum efficiency occurs when the friction and iron losses are practically equal to the copper losses.

Fig. 8.10 Typical series motor characteristics.

Series motors are used for work demanding large starting torque, such as locomotives, cranes, etc. In addition to the large starting torque, there is another characteristic of series motors which makes them especially desirable for traction purposes. Assume that a shunt motor is used to drive a locomotive. When the vehicle ascends a grade, the shunt motor maintains the speed at approximately the same value that it has on level ground. The motor therefore tends to take an excessive current. A series motor, on the other hand, automatically slows down upon reaching such a grade, because of the increased current. It therefore develops more torque at reduced speed. The drop in speed allows the motor to develop a large torque with but a moderate increase of power. Hence, a series motor could be made smaller than a shunt motor operating under the same conditions.