Site pages

Current course

Participants

General

Module 1: Fundamentals of Reservoir and Farm Ponds

Module 2: Basic Design Aspect of Reservoir and Far...

Module 3: Seepage and Stability Analysis of Reserv...

Module 4: Construction of Reservoir and Farm Ponds

Module 5: Economic Analysis of Farm Pond and Reser...

Module 6: Miscellaneous Aspects on Reservoir and F...

Lesson 31 Runoff Inducement Methods

31.1 Introduction

The term water harvesting is used to describe the process by which water is collected from an area, that may have been modified or treated to increase surface runoff, and stored for use later. This chapter describes some of the methods and materials used to induce runoff in agricultural systems. Some general ideas and concepts are presented on runoff inducement techniques (such as surface modification, cover sheets, and soil surface treatment) that are feasible for use in arid and semi-arid regions of the world. The advantages and disadvantages, cost, and conditions favouring each method are also discussed.

31.2 Methods for Improving Runoff

The success of a water harvesting system depends mainly on the runoff efficiency of a catchment which can be defined as the runoff produced per unit rainfall on a given piece of land. The runoff efficiency of a runoff inducement method depends on land factors like vegetal cover interception, depression storage on land, infiltration rate of soil, antecedent soil moisture and precipitation factors like threshold quantity of rainfall, its intensity, amount and duration. Since manipulation of rainfall is a very difficult process, most runoff inducement methods are different ways and means of manipulating and modifying the land surface. Often the catchment area needs to be modified to increase surface runoff. Some of the methods followed in regard to increase the catchment runoff are through:

Modification of the topography or soil surface

Modification of the soil

Covering the surface with an impermeable layer

There is not a single technique or method that is best in all situations. The best techniques to use for the purpose are chosen depending on topography, soil condition, storage devices, labour, availability of treating/covering materials, and intended use of the water harvested. The cost of alternative water sources and the importance of water supply determine whether the costs involved are justified?

The total cost for preparing a catchment area includes two main items such as the cost of materials and the cost of labour. Some materials and installation techniques are labor-intensive but have relatively low capital costs. This type of techniques may be suitable for areas where labour is cheap. Other approaches may have high capital cost but require a minimum of labour, e.g. mechanized compaction. Such techniques may be appropriate in areas where labour cost is very high. Usually the water harvesting systems used in runoff farming are constructed from materials that are cheap, locally available, and handled easily.

31.2.1 Creating Shallow Channels

In long-slope water harvesting systems the yield of runoff water can be increased substantially by creating shallow channels within the catchment area. Depending on local conditions, the work involved can be done manually or by heavy machinery. Special care is needed to avoid soil erosion within those channels. The construction of small bunds perpendicular to the direction of flow slows down the running water, promotes sedimentation and reduces the erosion risk.

31.2.2 Clearing the Catchment

Clearing rocks and vegetation from the catchment area usually reduces infiltration rate and increases runoff. When the vegetation is removed the fine soil particles that are detached due to raindrop impact help seal the surface which results in reduced infiltration and increased runoff. Only some of the gravels, stones and vegetation need be cleared, with little modification to the topography or surface structure. Clearing the catchment in this way can be a very economical way of harvesting rainwater in arid lands if erosion is limited and low-cost hillside land is available. However if erosion is severe, soil conservation measures have to be selected that do not significantly reduce runoff water yield.

31.2.3 Smoothing the Soil Surface

The soil surface may be smoothed by removing small obstructions such as ridges and furrows across the slope of the land. In this method small amount of topographic modification is required. However, the labour requirement and use of machinery for the purpose of smoothing depend on the topography and soil conditions. Adoption of the method of smoothing the soil surface alone is not that efficient for runoff generation. Rather runoff efficiency improves by laying out a system of ditches and ridges in a fish-bone pattern on suitable slopes. These treatments are effective on suitable soil types with appropriate topography.

31.2.4 Compacting the Soil Surface

Compaction of the soil surface of the catchment reduces infiltration rate and increases runoff. The slopes are graded and compacted manually or mechanically. For manual compaction, a hand hammer may be used; mechanical compaction requires a tractor and rubber-tired roller or other compacting machinery, depending on field conditions and the area to be compacted.

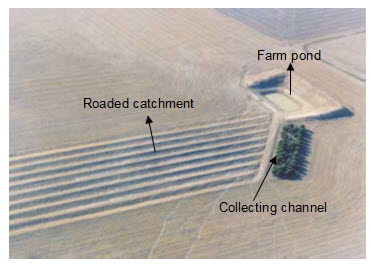

Compacting and smoothing methods have been used successfully in roaded catchments in Western Australia. A roaded catchment is a water-harvesting structure designed to increase the amount of run-off from the catchment above a dam (Fig. 31.1). The ‘roads’ of a roaded catchment are parallel ridges of earth with batters or side slopes that cause run-off to be directed into troughs or channels. The surface is lined with clay and compacted to make it smooth and impervious to reduce infiltration and increase run-off. In this area, an average annual rainfall of 500 mm is received during seven winter months. The surface layers of the soil are sandy, while the subsoil is clayey. The sand is moved into rows, exposing the clay. This is then shaped and spread to cover the whole surface. The ridges discharge induced runoff water into a channel which conducts it to a tank. The major advantage of this method is that the system uses the existing soil and can be built up with readily available equipment. Compacting and smoothing the steep road surfaces is most important, and this is achieved by tractors and rubber-tired rollers. The method of runoff inducement may be used in other arid and semi-arid areas having similar soil and topographic conditions. However the high capital cost of the technique makes it unsuitable for many developing countries.

Fig. 31.1.A typical farm pond with roaded catchment.

(Source: Xiao-Yanet al., 2004)

31.2.5 Surface Sealing

Surface sealing involves chemical treatments either sprayed on to the catchment area or mixed into the soil surface to reduce or stop water infiltration. Many types of materials have been tested. Unfortunately many of them work only on specific soil types and are not successful for long-term use.

Sodium salts, when applied, clay particles of the soil disperse, swell or break down into small particles, which in return clog the soil pores and reduce the infiltration rate. Reduction in infiltration rate results in increasing runoff. These salts are widely used as a soil sealant because of their low cost, ready availability and ability to retard weed growth. However, soil erosion might be a potential problem with this treatment. Negative effects on plant growth by this kind of treatment have not been observed.

The treatment consists of mixing a water-soluble sodium based salt (NaCl) into the top 2 cm of soil at a rate of about 1t/ha. The catchment area is then wetted and compacted to make a smooth surface. This treatment requires a soil containing 20% or more of kaolinite or illite type clay. The sodium salt disperses the clay particles which clog the soil pores and ultimately, the permeability of the soil is reduced. It is observed that some of these chemicals work perfectly as water repellent but enhance the weathering ability of the soil.

A second type of soil surface modification treatment is the application of water-repellent chemicals. These chemicals when applied to the catchment area create a hydrophobic or water repellent soil surface. It does not change the porosity of the soil, but instead changes the surface tension characteristics between the water and soil particles. One of the simplest water-repellent chemicals is sodium silanolate (H12Na4O4Si4). This is applied in a water solution and forms a water-repellent layer 1-2 cm deep with an effective life of 3-5 years. The treatment does not provide any soil stabilization; hence wind and water erosion can be a problem. It is not suitable for soils containing clay more than 15%.

Another water repellent treatment consists of spraying molten, refined, low melting point paraffin wax onto the prepared soil surface. The wax is initially deposited as a thin layer on the surface. As the sun heats the surface, the wax partially melts and moves deeper into the soil, coating each individual soil particle with a thin wax layer and rendering the soil water repellent. This treatment is best suited to soil containing clay less than 20% and on catchment sites where the soil temperature will exceed the melting point of the wax during part of the year. Wax-treated plots yield on an average 90% of the rainfall as runoff as compared to 30-40% from untreated plots. However the paraffin wax does not provide significant soil stabilization and the treatment is susceptible to water and wind erosion.

To overcome the difficulties of using paraffin wax in inducing runoff, the wax may be emulsified by using low-cost additives. The emulsified wax can be applied easily to catchment plots using a small sprayer. The use of the wax thus helps increase the amount of runoff from small plots.

31.2.6 Impermeable Coverings

Instead of making the soil itself the water-shedding surface, it may be better in some situations to cover it with a waterproof layer. Low and high density plastic films and other thin sheeting materials including butyl rubber, asphalt membranes, and highway surfaces have been investigated as potential soil coverings for water harvesting catchments. Bitumen or asphalt are best suited to fine sandy soils, but have an effective life of only 2-5 years. However, the thin film coverings are susceptible to damage by wind and/or sunlight. Partial covering of the ground with plastic sheets around trees also contributes to evaporation reduction and increase in rainwater collection.

One of the simpler techniques of utilizing low cost sheets of plastic or tar felting sheets used in roofing is to place a shallow layer of clean gravel on the sheet after it has been positioned on the catchment surface. The sheets of plastic or the tar paper provide the waterproof membrane and the gravel protects it from wind and sun. An efficient runoff producing catchment surface can also be made by covering asphalt with a better quality film of gravel layer on top. The asphalt layer helps binding the film of gravel to the catchment surface, while the film protects the asphalt from oxidation. This treatment requires periodic maintenance to ensure the sheeting remains covered with gravel. In such cases, the runoff is essentially 100% of all precipitations in excess of 2 mm. Such catchments, if carefully constructed and maintained, can last for 20 years. Windblown dust particles trapped in the gravel layer develops a potential seedbed for plants, which would otherwise negatively affect runoff efficiency. The treatment is relatively inexpensive subject to readily availability of clean gravel. Experiments conducted in the USA on the use of asphalt as catchment cover demonstrate the following:

Strong and durable catchments, for runoff inducement and water harvesting, can be constructed by spraying asphalt on the surface of loamy sand and sandy loam soils.

The larger the catchment size, the lower the cost of construction per unit area.

In areas with high solar radiation and low precipitation, runoff from asphalt catchments is coloured by asphalt oxidation agents. This coloured water was consumed by cattle without problem.

An effective treatment used for supplying water for wildlife and irrigation is the asphalt-fabric membrane. In this system random-weave fiberglass matting or synthetic polyester engineering filter fabrics is unrolled on the prepared catchment surface and saturated with an asphalt emulsion. Three to 10 days later, a final asphaltic emulsion seal coat is brushed on the membrane. These membranes are relative resistant to damage by wind, animals, and weathering.

Many conventional construction materials such as concrete, sheet metal, or artificial rubber sheeting can be used on water harvesting catchments. These materials are relatively expensive, but when properly installed and maintained have an effective life up to 20 years. They are useful where gravel is readily available and maximum runoff is not required.

Another study in China evaluated runoff characteristics of six surface treatments relative to rainfall amount and intensity, and antecedent rainfall during naturally occurring rainfall events in the semi-arid loess regions of northwest China. The surface treatments included two basic types, i.e. earthen (natural loess slope and cleared loess slope) and barrier type (concrete, asphalt fiberglass, plastic film, and gravel covered plastic film). The results indicated that runoff and runoff efficiency of the earthen surface treatments were more governed by the amount of rainfall. As presented in Table 31.1, asphalt fiberglass had the highest average annual runoff efficiency of 74-81%, followed by the plastic film (57-76)%, gravel covered plastic film(56-77)%, concrete (46-69)%, cleared loess slope (12-13)% and natural loess slope (9-11)%. Antecedent rainfall had an obvious effect on runoff yield for the cleared loess slope, natural loess slope, and concrete. The threshold rainfall was 8.5, 8.0, and 1.5 mm for the natural loess slope, cleared loess slope, and concrete treatment, respectively, without antecedent rainfall effects, and 6.0, 5.0 and 1.2 mm, respectively with antecedent rainfall effects. Due to the impermeable surface,

Table 31.1. Characteristics of methods for inducing runoff on catchment areas to enhance water harvesting

*(Source: Xiao-Yanet al.(2004)), **Plastic films not UV resistant

|

Treatment |

Runoff efficiency (%) |

Estimated life (years) |

|

Clearing of catchment |

10-15 |

2-10 |

|

Cleared loess slope |

12* |

5-10* |

|

Smoothing of soil surface |

15-20 |

2-5 |

|

Compacting the soil surface |

20-30 |

2-3 |

|

Surface sealing |

30-80 |

3-6 |

|

Impermeable coverings concrete |

69* |

10* |

|

Plastic film |

76* |

0.5** |

|

Gravel-covered plastic film |

77* |

0.8** |

|

Asphalt fibreglass |

81* |

5* |

antecedent rainfall had little effect on the runoff yield for the asphalt fiberglass, plastic film, and gravel covered plastic film treatments, which had threshold rainfall of 0.1,0.2 and 0.9 mm, respectively.

Not all of these characteristics may be obtained with any one treatment. Table 31.1 lists design estimates of runoff efficiency and average expected life of material for some common catchment treatments of runoff inducement.

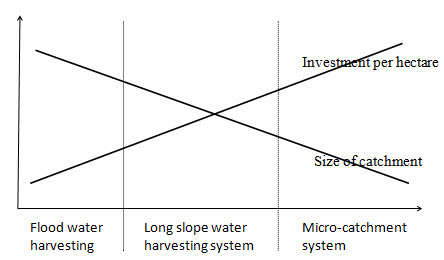

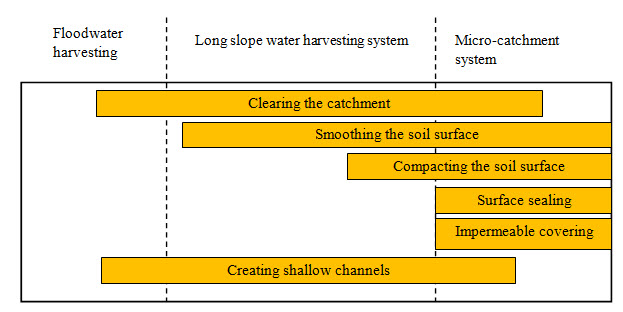

Some of the more expensive methods have higher runoff efficiency (> 90%) and longer life (15-20 years) than the less expensive methods. More labour intensive and cheaper methods usually have low runoff efficiency between 10 to 20%. Fig. 31.2 and Fig. 31.3 show the general trend of investment requirements and suitability of various runoff inducement techniques in relation to the type of water harvesting system. Selecting the most appropriate method still depends on an expert assessment of technical, cultural, socioeconomic, and political considerations.

Fig. 31.2. Relationship between catchment size and investment (labour and/or capital) for various runoff inducing practices.

(Source: Xiao-Yanet al., 2004)

Fig. 31.3. Suitability of runoff inducement techniques to various water harvesting systems. (Source: Xiao-Yan et al., 2004)

31.3 Advantages and Disadvantages

Many runoff inducement methods are site and area specific. The best method to use for a specific area depends upon the catchment characteristics, topography, rock type, and soil conditions. The socioeconomic condition of the stakeholders is also an important consideration. Some of the desirable characteristics of catchment area treatments to be used for runoff inducement are:

The resulting surface of the treated area should be relatively smooth and impermeable to water.

The treated catchment area should have a high resistance to weathering damage (hot and cold) and resistance to deterioration from internal chemical and physical properties.

The treatment should be able to resist damage by hail, intense rainfall, wind, occasional animal traffic, moderate flow of water, plant growth insects, birds and burrowing animals.

The treatment should be inexpensive on an annual cost basis, and should permit minimum site preparation and construction costs.

Operation and maintenance should be simple and inexpensive, and the lifespan of the treatment should be as long as possible.

Runoff water collected from the treated area must be nontoxic to plants and should not be harmful to human health.

31.4 Further Considerations

Care is needed to minimize the side effects of runoff inducement methods. Poorly designed and managed rainwater harvesting can lead to soil erosion, soil instability, and local flooding. However data on rainfall intensity, variability and hydro-geology are lacking in many developing countries, which hampers selection of the appropriate method.

Soil erosion is a constant concern and can be controlled if the slope is short and not too steep. Slope of the drainage area affects the quantity and quality of runoff. In long slope systems the most efficient water harvest is from a small, gently sloping catchment with good soil conditions (or from steep catchments with rocky surface).

A rainwater harvesting catchment must withstand weathering and occasional traffic. However most soil treatments have a limited lifespan and must be maintained and renewed periodically. They also require occasional maintenance because of cracking caused by unstable soil, oxidation and weathering; plants growing up through the ground cover or treated soil; and penetration by grazing animals.

Runoff water may be contaminated by the materials used to enhance runoff. If new materials are to be deployed, it should be done on small scale first, before this material is applied at large scale.

Dry-lands often have rich ecosystems, consisting of many species of flora, fauna, and microorganism. The preservation of this diversity must be taken into consideration when clearing sites for water harvesting.

Key words: Runoff inducement, Catchment clearing, Runoff efficiency

References

Xiao-Yan, L., Zhong-Kui, X. and xiang-Kui, Y. (2004).Runoff characteristics of artificial catchment materials for rainwater harvesting in semiarid regions of China. Agricultural Water Management (Elsevier), 60(3-31):217-226.