Site pages

Current course

Participants

General

MODULE 1. Introduction to mechanics of tillage tools

MODULE 2. Engineering properties of soil, principl...

MODULE 3. Design of tillage tools, principles of s...

MODULE 4. Deign equation, Force analysis

MODULE 5. Application of dimensional analysis in s...

Module 6. Introduction to traction and mechanics, ...

Module 7. Traction model, traction improvement, tr...

Module 8.Soil compaction and plant growth, variabi...

LESSON 8. ASSESSMENT OF THE DYNAMIC PROPERTIES OF SOILS (continued)

8.1. Field measurements of soil shear strength.

The direct shear and triaxial shear tests are laboratory procedures to measure the shear strength. Soil samples must be taken from the field to perform these tests. The samples may get disturbed and their shear strengths may be altered in the process. To avoid this, field methods to measure the shear strength have been developed. Two methods are most commonly used for measuring the soil shear strength in the field. They are,

i. Round shear box apparatus

ii. Vane type shear apparatus

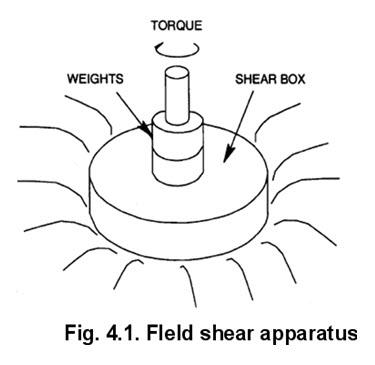

i. Round shear box apparatus

The first method is a round shear box which is rotated after it is inserted into the soil as shown in Figure 4.1. The box is driven into the soil until the top of the box is in contact with the soil surface. The soil is excavated carefully outside the box before applying the torque to shear the soil. The soil at the bottom of the box is sheared.

The shear strength is calculated using the following equation:

-------------- (4.1)

-------------- (4.1)

where,

s = soil shear strength

M = moment at failure

r = shear box radius

Markers are placed on the soil inside the box that are visible through small holes in the top of the box. The markers are used to ensure that the soil shears uniformly.

To overcome the problem that the soil located near the outer edge of the shear box must move considerably farther than that near the center, a narrow annulus has been designed as a shear box. Shear strength for the narrow annulus shaped box is calculated from the following equation:

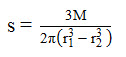

-------------- (4.2)

-------------- (4.2)

where, r1 and r2 are the inner and the outer radii of the annulus, respectively.

The field apparatus described above requires excavating the soil at the outside after inserting it into the ground.

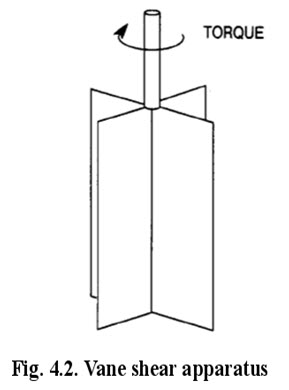

ii. Vane type shear apparatus

A vane type shear apparatus is shown in figure 4.2. It does not require excavation asw in the case of round shear box apparatus.

Once driven into the soil the rotation causes shear of soil along the surface of the cylinder that is generated by the vanes. This device may be used at greater depths. Measurements can be made at increasing depths without extracting the shear device so that a rather complete strength profile of natural soil conditions can be obtained. The vanes have a height-to-radius ratio of 4:1. The vane shear apparatus provides no means of varying normal load. Shear strength is computed as:

------------------- (4.3)

------------------- (4.3)

where, r is the radius of the circle inscribed by vane tips.

ii. Friction

All tillage operations involve a sliding action of soil over some surface of the tool. Friction of soil against a tool having large contact areas represents a significant component of the draft requirement. Friction is also involved when two rigid bodies of soil move with respect to each other.

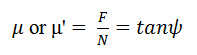

Hence, there are three types of frictional parameters in problems involving soil dynamics. These are soil metal-friction (μ′), soil-soil friction (μ), and soil internal friction (tan φ). Soil internal friction (tan φ) has been discussed in reference to soil shear strength in equation 2.10. To determine soil-soil friction and soil-metal friction, we make use of Coulomb’s concept of friction coefficient,

------------------ (4.4)

------------------ (4.4)

μ = coefficient of friction (soil on soil)

µ’= coefficient of friction (soil metal-friction)

F = frictional force tangent to the surface

N = normal force (perpendicular to the surface)

ψ = friction angle

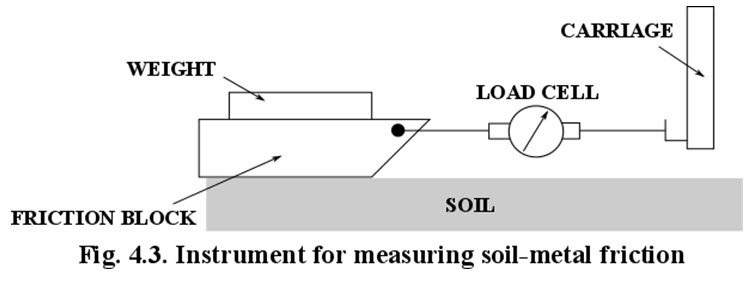

An apparatus to measure soil-metal friction is shown in Figure 4.3.

Frictional force corresponding to different normal loads are measured and plotted against the normal loads. The slope of the line is the coefficient of friction. It must be pointed out that there is a difference between the soil-soil friction and the internal friction angle. In soil-soil friction phenomenon, the soil moves as a rigid body against another soil surface.

The internal friction of soil comes into play when soil fails under shear load ing. Therefore, if we continue to apply shearing load in a shear test after failure, then we will measure soil-soil frictional behavior.