Site pages

Current course

Participants

General

MODULE 1. Introduction to production of agricultur...

MODULE 2. Advance in material for tractor and agri...

MODULE 3. Advanced manufacturing techniques

MODULE 4. Heat treatment of steel

MODULE 5. Industrial lay out planning and quality ...

MODULE 6. Economics of process

MODULE 7. Techno economic feasibility of project r...

MODULE 8. Servo motors, drives and controllers

MODULE 9. CNC controllers for machine tools

MODULE 10. CNC programming

MODULE 11. Assembly and plant automation storage a...

LESSON 21. CASE STUDY ON AGRICULTURAL TINES

2.0 Introduction

Agricultural tine is a part of cultivator and is fitted with a plough on it. A cultivator has usually 7-11 tines depending upon the make of the tractor with which it is used.

2.1 Product requirement

2.1.1 Quality and standards

The Bureau of Indian Standards has laid down specification No.SI:7565(l) for manufacture o tines for tractor operated cultivators which may be followed for quality production of tines

2.1.2 Production capacity

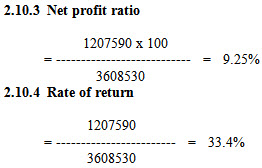

This project profile envisages production of 162000 nos. of Agricultural Tines of assorted sizes per annum. The design of the may, however, change according to its application i.e. the make the make the size of tractor to which the cultivator will be fitted for its use.

2.1.3 Month and year of preparation : August, 1992.

2.3 Market

The demand for cultivators picks up in the month of April to June and September to November and so is the remand for tines. According to estimates, there are 12 small scale units manufacturing agricultural tines in the country.

The demand for agricultural tines is directly linked to the demand for cultivators and due to mechanisation on the field of agriculture in the country. There exists good scope for the item for development in the small scale sector.

2.4 Basis & presumption

-

This project profile is based on 6 working hours a day and 25 days in month and the break even efficiency has been calculated on 75% capacity utilisation basis.

-

The gestation period in implementation of on the project may be in the tune of 6 to 8 months which includes making all arrangements, completion all formalities, market survey and tie-ups etc. Once all the arrangements are made and quality/standard achieved the project capacity may be achieved, the end of one year. However, a detailed PERT CPM/chart with implementation period has been given in the report.

-

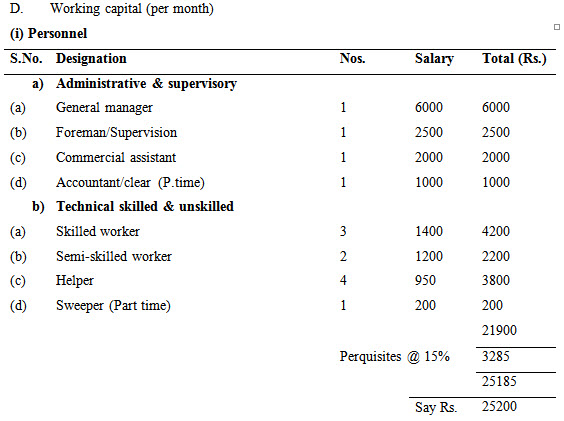

The normal wages are salaries being paid in the industry to various grade of personnel have been considered and also the provision of minimum wages has been taken into care.

-

The rate of interest both for fixed and working capital has been taken as 20% p.a.

-

The margin money as applicable to general categories to entrepreneurs may be 25% of project cost.

-

The payback period may be 5 years after the loan has been disbursed.

-

The rental period of accommodation for office etc. has been taken @ Rs. 15 per sq. metre and for workspace and for open space/others the same has been considered @Rs. 10 per sq. metre.

2.5 Implementation schedule

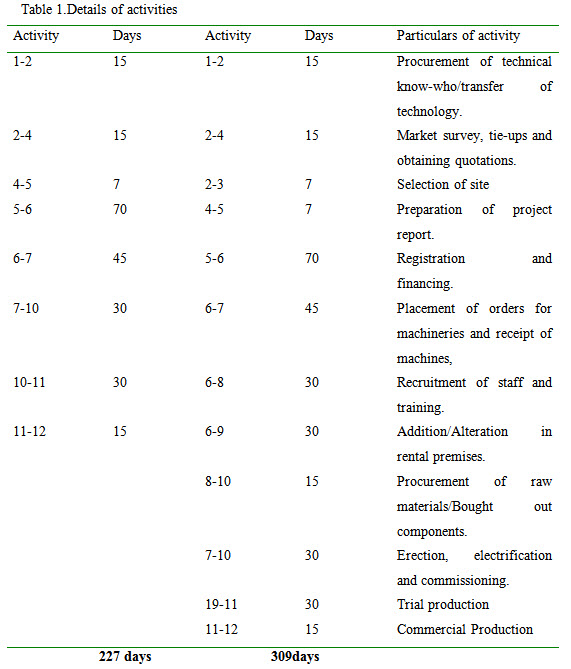

The implementation of the project includes various jobs/exercised such as procurement of technical know-how, selection of site, registration, financing of project, procurement of machinery and raw-material etc., recruitment of staff, erection/commissioning of machines, trial production and commercial production etc. In order to efficiently and successfully implement the project in the shortest period the slack period is curtailed to minimum possible and as far as possible simultaneous exercise is carried out. In the view of above a CPM-PERT Chart has been illustrated below according to which a minimum period of 227 days in involved in finally starting the product on commercial basis. By following this process a time period of 82 days can be saved.

2.5.1 Details of activities: The CPM of the activities is given at Table 1.

Table 1.Details of activities

2.6 Technical aspects

-

The manufacture of agriculture tines involves operations like cutting of rectangular flats to sizes on power press and the heating then in the oil fired furnace in bulk quantity. After this the flats are forged at both ends of power press to give desired shape. Simultaneously, the holes are made on one side followed by flatting straightening of the same on power press and drilling of holes on other side with drilling machine. After this final inspection and the testing is undertaken. The tines are then coated with red oxide primer and packed. The provision for milling machine and lathe has been made for rectification/manufacture of dies required for the process.

-

No Indian standard specification has been laid down for exclusive manufacture of tines. However, BIS has lain down IS: 7565(I) for the manufacture of tractor driven cultivators which may be referred to for manufacture of quality products of line.

-

No sophisticated technology for manufacture of tines is required. The use of proper jigs and fixtures will not only increase rate of production but will also ensure quality tines.

-

The cost of final product will vary according to the type of raw material used.

-

The motive power required for the project is about 30 kw.

-

Provision has been made in the oil fired furnace for proper outlet of smoke through the chimney of proper height. Exhaust fans should also be fitted on the four sides of the walls at roof level. By these arrangements pollution will be controlled.

-

No specific energy conservation systems have been providing. However, the oil fired furnace should have heat-resistance fire bricks to avoid heat dissemination.

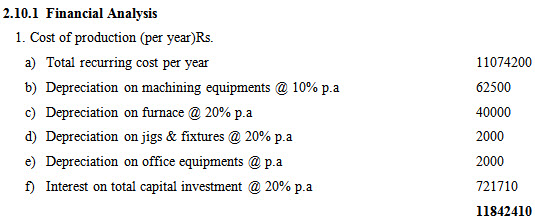

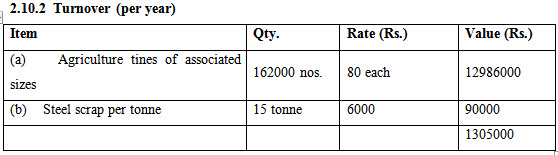

2.7 Financial aspects

2.7.1 Fixed capital: land & building

A built-up area of 400 sq. meter on rental-basis as follows:

I. For office, stores, parking etc. 100 sq .meter

Rent @Rs.15/-per sq. meter 1500

II. For work shed and open space etc. 300 sq. meter

Rent @Rs.10/-per sq. meter. 3000

--------

4500

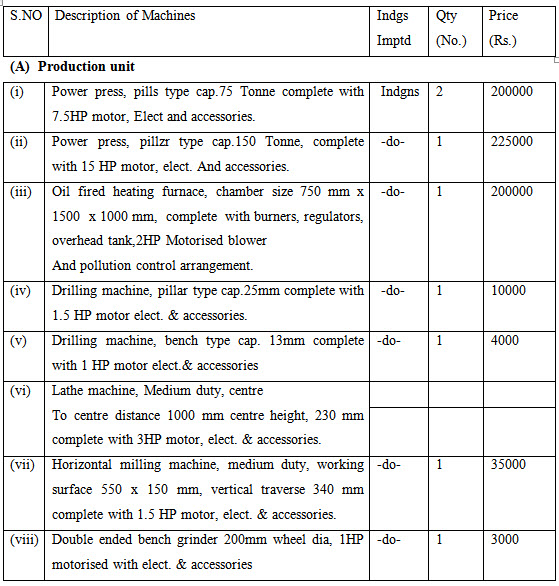

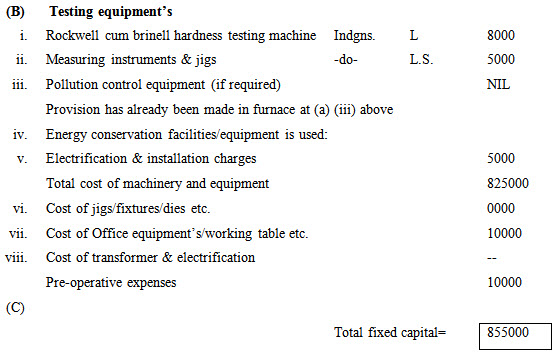

2.8 Machinery & equipments : The details of machinery and equipments is given at Table 2.

2.10 Machinery utilisation

The bottleneck operation in the project will be forging on power press. The utilisation of the major machinery facilities has been considered to the tune of 75% which may be achieved by the end of a year after commissioning plant.

2.11 Additional information

(a) The design/specifications of agricultural tines may differ in view of there is source of application. The cultivator incorporation the tines may be used with various makes of trailors such as ford, HMT, Ziether, Eicher, etc. etc. Therefore the weight of the tine may also charge accordingly. However in this project report the same has been considered on an average of various items.

(b) As regards alternate method of manufacture of agricultural tines, the tines can also be manufactured by hot forging on forging hammers. Since the cost also be manufactured by hot forging on forging hammers. Since the cost of appropriate size of hammer required for tines is quite on higher side an SSI unit proposing to work at medium level may to find it vlable & easy to manufacture the same. In case the manufacturing with forging hammer is considered, the other working details will be the same as indicated in the above project profile.

2.12 Address of machinery & equipment suppliers

(a) Power presses

(i) M/s. Basanth Industries,

369, Basanth Road Industrial Area-6, Ludhina (Punjab)

(ii) M/s. Birds Drawing & Power Press Industries

St. No. 7, 1169 Vishwakarma Colony, Link Road,

Ludhiana-141603(Punjab)

(iii) M/s. Prem Engg. Works

Ckhia Industrial Estate, New Delhi-110020

(b) Furnace

(i) M/s.Walking Engg. Co.

Sanasia Market, Vishwas Nagar,

Shahdara-Delhi-110030

(iii) M/s. Manti Oil Furnance Co.

Link Road 689, Industrial Area,

Ludhiana-141003.

(c) Machines

(i) M/s.Sandhu Mechnical Works

Industrial Area ‘A’, Ludhiana-141003

(ii) M/s. R.K. Machines Tools

Industrial Area ‘A’, Ludhiana-141003

(iii) M/s. Prerfecst M/c. Tools

Jeewan Tara building, Parliament Street,

New Delhi-110001

(d) Milling machines

(i) M/s. R.K. Machine Tools

Industrial Area ‘A’, Ludhiana-141003(Punjab)

(ii) M/s. Bhambar Machine Tools(India)

493, Janatha Nagar, Gill Road, Ludhiana-141003.

(e) Drilling machines

(i) M/s. Mahalaxmi Engg. Works

27, DLF Industrial Area,

Najafgarh, New Delhi-110015.

(ii) M/s. Indian Tools Corpn.

3-180, Industrial Area, Jalandhar-144004.

(iii) M/s. Fine Engineers

Kashmir Road, Batala-143505

(iv) M/s. Birdhi Mech. Works

G.T. Road, Near Manju Cinema, Ludhiana-141003(Punjab)

(f) Bench grinder

(i) M/s. Pem Brothers

9/16, Indl, Area, Kirti Nagar, Delhi.

(ii) M/s. Jeet M/c. Tools Corpn.

48, Shardhanand Marg, Delhi-11006.

(iii) M/s. Globe Engg. co.

2225,G.B. Road, Delhi-110006

(g) Tools

(i) M/s. Auto Teat

B-5, D-STDC, Indl. Complex,

Rohtak Road, Nangloi, Delhi-110041.

(ii) M/s. Mithard & Co.

G.T. Road, Millerganj, Ludhana

(iii) M/s. Philips India Ltd.

Siva Nagar, Estate, Dr. A.B. Road,

Bombay-400018.

(h) Addresses of raw materials suppliers:

Local/neaby suppliers/manufactures.

References:

Ashish Shrivastav, Project Report-Techno Economic Feasibility

Ex. Manager, Centre for Entrepreneurship Development Madhya Pradesh, Bhopal