Site pages

Current course

Participants

General

Module 1. Role of mechanization and its relationsh...

Module 2. Performance and power analysis

Module 3. Cost analysis of machinery- fixed cost a...

Module 4. Selection of optimum machinery and repla...

Module 5. Break-even point and its analysis, relia...

Module 6. Mechanization planning

Module 7. Case studies and agricultural mechanizat...

Topic 8

Topic 9

Topic 10

Lesson 17. Selection of matching farm equipment

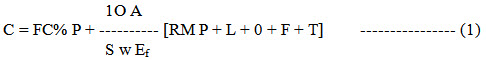

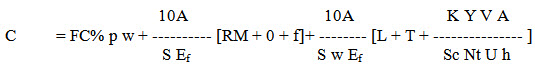

An important aspect while buying a new machine is to make the decision regarding the size of the machine required. Economic selections of field equipment are a complex problem. Size selection is mainly based on anticipated performance and costs. For selecting proper capacity of a field machine, the minimum cost of the machine can be calculated by using the following equation:

Where,

C = Annual cost of operating the machine, Rs/year

FC% = Annual fixed cost percentage, decimal

P = Purchase price, Rs

A = Annual use, ha

S = Forward speed, km/h

w = Width of machine, m

Ef = Field efficiency of machine, decimal

RM = Repair & maintenance costs, decimal of purchase price per hour

L = Labour wages, Rs/h

F = Fuel cost, Rs/h

0 = Oil cost, Rs/h

T = Cost of tractor use by machine, Rs/h

T = 0, if it is a self-propelled machine

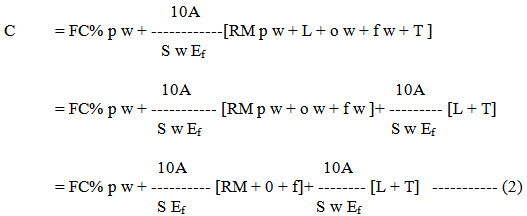

All variables in Eq. (18) depend upon the size of machine and so they must be expressed in terms of width (w).

Let, p be the purchase price per meter width of the machine, then P= p w

And so, RM P = RM p w

0 = o w

F = f w

Where,

0 = Oil cost/h/m of width of machine

f = Fuel cost/h/m of width of machine

Equation 1, thus becomes

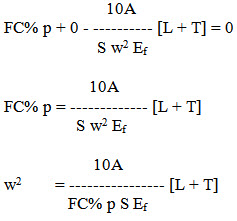

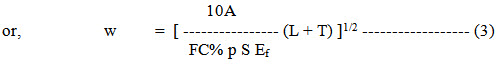

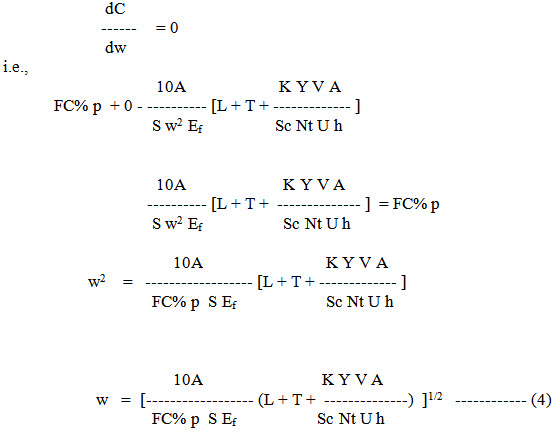

To determine the minimum point, differentiate equation (2) with respect to w and equate it to zero.

This is called the least cost width. The least cost width can also be determined by plotting equation (2) as shown in Fig. 1. The lowest point on the curve is least cost width. Values of fixed cost percentage as required in equation (3) are given in Table 1.

Timeliness of a field operation must be considered in selection of optimum width of a farm machine. Enough evidence is available to estimate timeliness loss factor (K) for most machine operations. If a crop requires multiple operations, say 2 cultivations then the K factor should be divided by 2. Similarly, for 3 or more cultivations K should be divided by 3 or more when used in the selection analysis.

Table 1: Values of fixed cost percentage

|

Service life (years) |

Values of FC% |

|

1 |

100 |

|

2 |

53 |

|

3 |

37 |

|

4 |

29 |

|

5 |

25 |

|

6 |

22 |

|

7 |

20 |

|

8 |

18 |

|

9 |

17 |

|

10 |

16 |

|

15 |

13 |

Source: Hunt (1977)

Equation 2 can be modified to include a charge for timeliness we get

Taking

Least cost width can be estimated by the equation (4).

Example: A farmer is having a 20 ha of land. The land is to be ploughed first before sowing of wheat crop. Farmer is using a 2-bottom mould board plough at a forward speed of 2.5 km/h for ploughing the field. The field efficiency of the plough is 70% and used for 8 hours a day. Find the least-cast-width of mould board plough. The sale price of wheat is Rs 6500.00 per tonne and productivity 5.2 t/ha. The price of mould board plough per meter width is Rs 15000.00. Given FC% = 16; K = 0.002, U = 0.8, Sc = 4 and Nt = 1.

Solution:

Labour cost (L) = Prevailing operator’s charge = Rs. 20.00/h

Total cost of operation of tractor (T) = Rs. 187.35/h (Calculated in section 3.3)

The least-cost-width of a mould board plough can be calculated by the equation (21),

i.e.

Thus, the least-cost width of mould board plough should be 3.52 m. Or in other words, the farmer might have to purchase 2 or 3 mould board ploughs depending upon the width of machine commercially available.