Site pages

Current course

Participants

General

Module 1. Introduction to human engineering

Module 2. Human performance and responses

Module 3. Working environment and work space design

Module 4. Rehabilitation scheme and DMR Act

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Lesson 3. HUMAN PERFORMANCE AND PERFORMANCE RELIABILITY

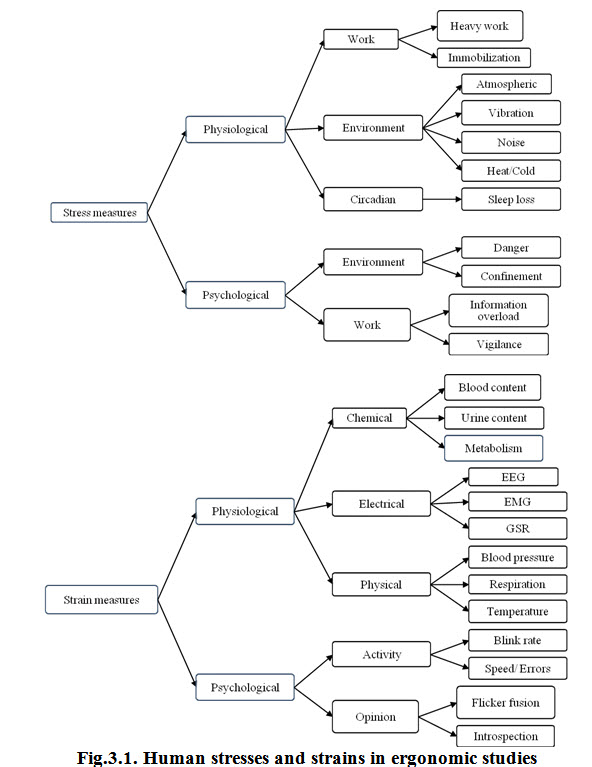

3.1 Human performance

The ergonomic aspects during application in agricultural machinery are of great importance as the operator has to operate the machine in field. The physiological as well as psychological fatigue affects performance of the operator and: hence, man-machine-environment system. There are many factors acting as stress on the operator during the work. These stresses may be due to workload, immobilization for longer duration work, ambient temperature, relative humidity, vibrations, noise, dust, smoke, exhaust gases, etc. A feeling of chance of accident during work, space confinement, overload of information to be handled, etc. results in psychological fatigue. During the ergonomic studies, these stresses can be measured in terms of strain on the operator. The most important among physiological strains are related to heart activity, respiration, discomfort, muscular fatigue, etc. During ergonomical studies, stress on eyes, hearing loss, errors, speed of work, work performance are some of the commonly used parameters for measurement of psychological/ mental strain.

During ergonomic intervention, subjects (operators or workers) are an integral part of the man-machine-environment system. The subjects must be medically fit and represent real user population in operation of the selected machinery.

3.1.1 Physiological factors for measurements

Physical activities stimulate certain physiological responses in human beings. These responses provide basis for human energy expenditure and fatigue. The physiological measurements are made generally in terms of heart and respiration activities.

3.1.1.1 Heart rate

Heart rate (HR) is the most reliable dependent parameter in ergonomic studies. This is because the heart rate has a direct and linear relationship with the human workload and stress. A starting period of 2-3 minutes is sufficient for heart/pulse rate to stabilize depending upon nature of exercise. Also, care has to be taken so that the operator is not subjected to workload leading to heart rate more than HRmax i.e. the upper limit of heart rate allowed during an activity.

Here,

HRmax (beats/min) = 220 – Age (years) ------ (1)

3.1.1.2 Respiration rate

The respiration is another basic variable in work physiology as it is linearly related to the workload. It is measured in terms of rate of volume of air inhaled or air exhaled or oxygen intake (VO2) or respiration rate. The greater the demands made on the muscle by the physical activities, the more air or oxygen is inhaled. The human energy expenditure (kilo Joule, kJ) is computed by multiplying the oxygen consumption (litres, l) with the calorific value of oxygen (20.88 kJ/l). The human workload has been categorized between light work and extremely heavy work depending upon heart rate or oxygen consumption (Table.1). Another criterion for measurement of human performance is Relative Load (RL) which is expressed as percentage of maximum aerobic power (VO2max); where, VO2max is volume of oxygen intake corresponding to HRmax calculated from established relation between VO2 and HR of an individual through subject calibration on treadmill or bicycle ergometer. Daily (8 hours) physical activity involving 35% of VO2max might be considered as an acceptable workload (AWL) for Indian workers.

Table 1. Limits of physiological responses and work category.

|

S. No. |

Work category |

Physiological response |

|

|

Oxygen consumption (l/min) |

Heart rate (beats/min) |

||

|

1 |

Light work |

< 0.5 |

Up to 90 |

|

2 |

Moderate work |

0.5 - 1.0 |

90-110 |

|

3 |

Heavy work |

1.0-1.5 |

110-130 |

|

4 |

Very Heavy work |

1.5-2.0 |

130-150 |

|

5 |

Extremely heavy work |

> 2.0 |

150-170 |

Source: Astrand and Rodahl (1986)

3.1.1.3 Discomfort rating

Body posture is one of the major factor which causes muscular fatigue and discomfort in the body. Uncomfortable body posture in different activities reduces work efficiency, capacity and safety of operator. The effect due to working posture can be measured in terms of overall discomfort rate and body part discomfort rate techniques. Table-2 gives the pain intensity score as measure of overall discomfort rate. The same score can be used for measurement of body parts discomfort rating.

Table 2. Pain intensity score as a measure of overall discomfort rating (ODR).

|

Subjective feeling |

ODR Score |

Subjective feeling |

ODR Score |

|

Comfortable |

0 |

Moderately painful |

4 |

|

Uncomfortable |

1 |

Highly painful |

5-6 |

|

Pain starts |

2 |

Very highly painful |

7-9 |

|

Slightly painful |

3 |

Extremely painful |

10 |

Source: Borg (1982)

3.1.2 Psychological factors for measurements

Certain working operations need overload of information, vigilance, danger or work performance accuracy. In such conditions, there is a higher load on sensory/neuro organs of the human body. Such situations cause higher stress on eyes, hearing system, brain activity, etc. resulting in poor work performance, more errors, more missing, lesser endurance, etc. These situations sometimes may lead to headache, drowsiness and even accident. These stresses can be measured in terms of reaction time measurement technique, blink rate, flicker fusion, critical hearing threshold level, speed & errors in work performance, etc.

3.2 Performance reliability

Performance reliability refers to quantitative values that characterize the dependability of system or components performance. The reliability of system can be defined in many ways:

Reliability is probability of a system performing its intended function over a given period of time under the operating condition encountered.

Reliability is the probability that a system will operate without failure for a given period of time under given operating conditions.

Reliability is mean operating time between two successive failures.

Reliability is integral of distribution of probabilities of failure free operation.

A state of fault is denoted by failure. It may be any of the three types:

Completely un-operational.

Operational but intended function is not performed satisfactory.

Serious deterioration in quality of its operation or unsafe operation.

Reliability in terms of probability of successful performance is applicable when the performance consists of discrete events. However; reliability in terms of mean time to failure is applicable in case of time for successful continuous performance before failure. If a system includes two or more components (machine or human or both), then reliability of the composite system will depend upon reliability of individual components and how they are combined within the system. Components can be combined within the system either in series or parallel or a complex system of series and parallel arrangement.

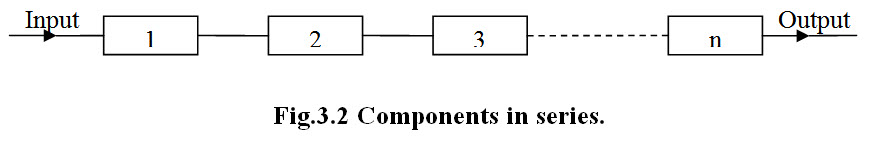

3.2.1 Components in series

System consists of number of components connected in series i.e. system operates if all are OK and system fails if any one of components fails. So weakest link i.e. component having lowest possibility of survival is the most critical one

Here, reliability of system (Rs) is product of reliability of each and every individual component connected in series.

Thus; Rs = R1 x R2 x R3 x……… Rn ------ (2)

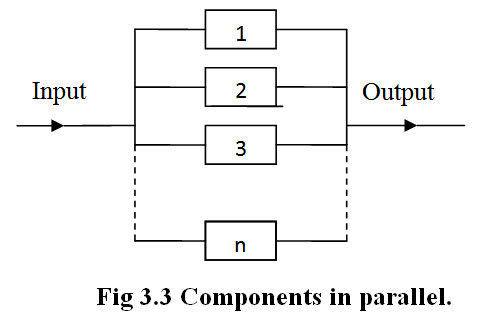

3.2.2 Components in parallel

Parallel system involves more cost, but is more reliable because if any of the components in parallel is functioning, that means system is in working order. The system fails only if each and every component connected in parallel fails simultaneously. Reliability of system (Rs) is determined after calculating probability of failure of the system (Qs)

Thus; Rs = 1 – Qs ------ (3)

Where, Qs = Q1 x Q2 x Q3 x……… Qn ------ (4)

Here, Qi is failure probability of ith component.

Suggested Readings:

Astrand P. And and Rodahl K. 1977. Textbook of Work Physiology. Mc Hill Corporation, New York.

Barry Kirwan. 1994. A Guide to Practical Human Reliability Assessment. Taylor and Francis.

Borg G. 1982. A category scale with ratio properties for intermodal and inter individual comparison. In: Geissler G.H. and Petgold P. (Eds) Psychophysical Judgement and the Process of Perception. VEB Dentsher, Berlin.

Bridger R.S. 1995. Introduction to Ergonomics. Mc Hill Corporation, New York.

Gavriel Salvendy.1997. Handbook of Human Factors and Ergonomics. John Wiley and Sons, Inc.

K.U.E. Kroemer and E. Grandjean. 2001. Fitting the Task to the Human: A textbook of Occupational Ergonomics. Taylor and Francis.

Mark S. Sanders and Ernest James McCormick,1993. Human Factors in Engineering and Design. Mc Hill Corporation, New York.

Nag P.K., Sebastian N.C. and Mavlankar M.G. 1980. Occupational workload of Indian agricultural workers. Ergonomics, 23 (2), 91-102.

Saha P.N., Datta S.R., Banrjee P.K. and Narayane G G. 1979. An acceptable workload for Indian workers. Ergonomics, 22 (09), 1059-1071.

Weybrew B.B. 1967. Psychophysiological Response to Military Stress. In: M H Apply and R Trumbull (Eds.), Psychological Stress Appleton Century Crafts, New York, USA.