Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

LESSON 4. Maintenance after 125 hours of operation

The 125-hour maintenance generally includes the following:

- Repeating the activities carried out in 50h maintenance schedule

- Changing crankcase oil

- Replacing the oil filter

- Servicing the crankcase breather

- Maintenance of tractor tyres

- Checking and servicing other parts of the tractor

1. Repeating the activities carried out in 50h maintenance schedule

2. Changing Crankcase Oil: The procedure for changing crank case oil is as under

a) Keep the tractor on the level ground. Operate its engine until thoroughly heated up

b) Remove drain plug

c) Allow crankcase to drain for several minutes

d) Change oil filter as described in steps (3)

e) Put drain plug again

f) Refill crankcase with new oil up to desired level

g) Start engine and operate it for few minutes at low rpm

h) Check oil leakage, if any

i) Check oil level with dip stick and keep it at recommended level.

Fig: 1.View of crank case oil (Courtesy: Escort Tractor)

3. Replacing the oil filter:

It removes 1/20 to 1/30th solids from the lubricating oil.

a) Locate oil filter

b) Clean it with used cloth

c) Loosen filter bowl and remove it

d) Remove oil filter cartridge and discard it

e) Clean inside of bowl with diesel

f) Install new gaskets

g) Install new filter unit

h) Refill the filter bowl

Fig: 3. View of oil filter (Courtesy: Escort Tractor

4. Servicing the Crank Case Breather:

a) Remove the crankcase breather

b) Wash filter element with diesel

c) Shake out excess cleaning fluid

d) Re-lubricate mesh with light crankcase oil

e) Remove excess oil

f) Reinstall the crankcase breather

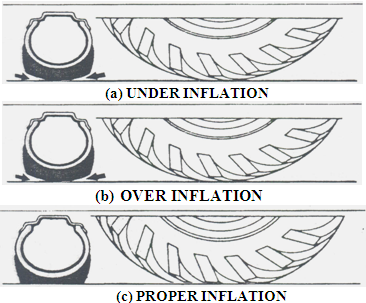

5. Maintenance Tractor Tyres:

a) Check Tyre inflation pressure in rear and front tyres with pressure gauge:

b) Recommended tyre pressure are:

Front - 1.1 to 1.25 kg/cm2 and Rear - 1.6 to 1.85 kg/cm2

c) Have proper tyre pressures & check with tyre pressure gauge

d) Check Tyres for any cuts

e) Check tor bruising, buckle etc

6. Checking and servicing other parts of the tractor

Check the following and if needed put some lubricating oil.

a) Generator/ Alternator bearing

b) Distributor shaft

Fig: 8. View of alternator used in tractor (Courtesy: Escort Tractor)

References:

Sharma D N. & S. Mukesh (2004). Design of Agricultural Tractor (Principles and Problems) Book Pub. Jain Brothers, New Delhi

Wadhwa D.S., Dhingra H. S. & Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual by, Department of Farm Machinery and Power Engineering, PAU Ludhiana