Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

LESSON 5. Maintenance after 250 hours of operation

The maintenance after 250 hours of operation service includes the jobs which are necessary for tractor to tune-up, which are as below:

1. Repeating the activities carried out in 125hours maintenance schedule

2. Valve clearance adjustment:

Proper valve clearance is very important because:

a) Valves give longer life

b) Increases fuel efficiency

c) Starting becomes easy

d) Maximum power generation

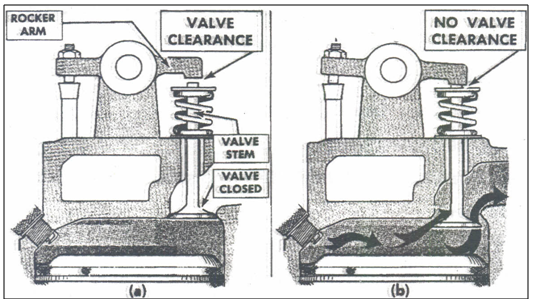

Fig: 1. View of valve system in tractors (Courtesy: Escort Ltd.)

Recommended valve clearances for tractor engine are given in table below:

|

Type of valve |

Recommended valve clearance |

|

Inlet valve |

0.008" |

|

Exhaust valve |

0.010 to 0.016" 0.004” (1 thou) = 0.1 mm |

Following steps may be followed to valve clearance adjustments:

Steps for valve clearance adjustment:

a) Check cylinder head bolts for tightness.

b) Slowly turn crankshaft until piston number 1, in the cylinder is at top dead centre (TDC) of compression stroke.

c) Check clearance with filler gauge between valve stem and rocker arm of both the valves.

d) If the clearance is not proper, loosen the adjusting screw nut and turn adjusting screw and check with filler gauge.

Fig: 2. Viewhowingnder head for tightness. of proper and improper valve clearance (Courtesy Lab. Manual PAU Ludhiana)

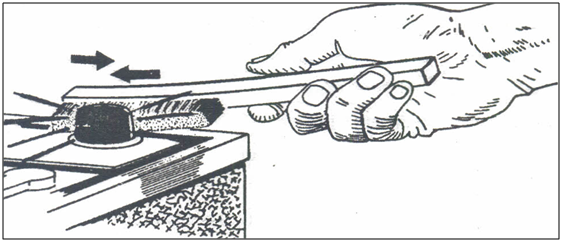

Fig: 3. View of removal of corrosion from battery terminal (Courtesy Lab. Manual by PAU Ludhiana)

e) Determine which cylinder fires next.

f) Turn crankshaft till the next cylinder in firing order is on compression.

g) Adjust valves, following the same procedure as on No. 1 cylinder.

3. Checking the battery:

a) Disconnect cable and ground strap from the battery terminals.

b) Clean cable clamps.

c) Remove dust and corrosion particles from battery terminals.

d) Brush soda and water mixture on top of the battery.

e) Apply coating of petroleum jelly.

f) Reconnect power cable and tighten properly.

Fig: 4. View of Battery used in tractor (Courtesy: Tractor Manual FPM Deptt. CCSHAU)

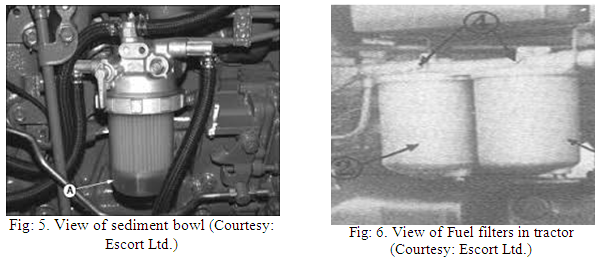

4. Cleaning the sediment bowl and fuel filters:

a) Remove the sediment bowl after closing the fuel supply. (Fig: 5.)

b) Remove gasket, if any.

c) Remove the filter or strainer and wash it with diesel. Pass the compressed air through it, so that dust and dirt can be removed more effectively.

d) Clean sediment bowl also. Open fuel valve and check whether fuel is coming from tank is free from dirt or not, if not make a free flow:

e) Assemble the sediment bowl and reinstall it over to the tractor.

f) Change fuel filter elements as per recommendation of the manufacturer.

Adjust tractor brakes:

a) Check what provision is made for the brake adjustment.

b) Jack up rear of the tractor until both the rear wheels clear the ground.

c) Release brake interlocks and locks.

d) Complete the preliminary arrangements for adjustment for first brake. Remove adjusting cover.

e) Tighten adjusting screw, adjusting rod or adjusting nut. The brake is tightened by shortening the linkage between the brake pedal and the brake. It is tightened until there is 15-20 mm of free travel on the brake pedal between its released position and the point where you can feel the brake starting to take hold.

Fig: 7. View of brake system (Courtesy: Escort Tractor)

f) Complete reassembling, or tightening of the locknuts to maintain adjustment.

g) Adjust second brake in the same manner as explained above.

h) Check to make certain that the brakes are equalized then lower tractor from the jacks.

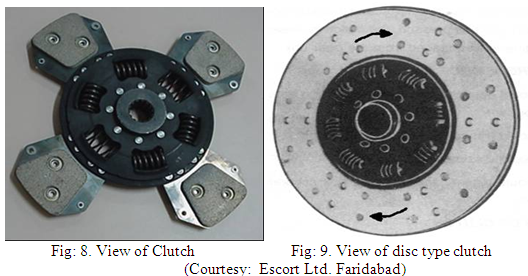

5. Adjust engine clutch: Adjustment of foot operated clutches: To adjust the foot operated clutch proceed as follows:

a) Determine from your operator's manual how much free travel in clutch pedal is needed. Recommendations vary from 15mm to more than 60mm.

b) Check clutch pedal for free travel.

c) Locate means provided for clutch adjustments.

d) Adjust linkage until clutch pedal has sufficient free travel.

e) Tighten lock nut so that it holds adjustment securely.

Adjustment of hand-operated clutches: To adjust the hand-operated clutch proceeds as follows:

a) Check clutch lever adjustment to determine whether adjustment is needed.

b) Disengage the clutch.

c) Place gear shift lever in neutral.

d) Remove hand-hole cover on clutch housing

e) Turn clutch by handle until locking mechanism is on side next to hand-hole.

f) Do the adjustment

g) Reassemble it.

References:

Sharma D N. & S. Mukesh (2004). Design of Agricultural Tractor (Principles and Problems) Book Pub. Jain Brothers, New Delhi

Wadhwa D.S., Dhingra H. S. & Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual, Department of Farm Machinery and Power Engineering, PAU Ludhiana

Sharma D N., Tractor Manual, Department of Farm Power and Machinery, CCSHAU

Service and Maintenance Manual of Tractor, Escort Ltd. Faridabad