Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

LESSON 6. Maintenance after 500 hours of operation

The 500-hour maintenance operation includes the following jobs:

- Repeating the activities carried out in 250 hours maintenance schedule

- Front-axle adjustment

- Servicing front-wheel bearings

- Maintaining the cooling system

1. Front-Axle adjustment

Toe-in adjustment

The front wheels are slightly drawn in at the front side in such a way that the distance between the front sides of wheels is slightly less than their back side. The difference is known as toe-in and varies in the range of 4±2 mm. To get the desired font wheel toe-in, procedure followed is as under:

- Bring the tractor on a levelled ground with front wheels in straight-ahead position. This can be done by moving the steering wheel from one extreme to another extreme position and then bringing it in the middle of its revolution.

- Adjust the wheel alignment apparatus between the front wheels both at the front and the rear side and measure the distances on the scale provided. Adjust the toe-in if the need be.

2. Servicing Front-wheel Bearings

A). Disassembling the Front-wheel bearings

To disassemble the front-wheel bearing, proceed as follows:

- Raise the front wheels off the ground.

- Clean dirt from wheel and hub cap and remove hub cap.

- Remove cotter pin and adjusting nut.

- Remove thrust washer and outer bearing.

- Pull wheel off the spindle.

- If the inner bearing remained in the hub, remove it.

B). Clean the Front-wheel Bearings as below:

- Wash bearings thoroughly.

- Clean, hub, hub cap and spindle with solvent.

- Remove solvent from the bearings and other washed parts.

- Examine bearings for wear.

- Examine grease-retainer ring and seal. Replace if damaged.

C). Greasing & refitting of front wheel bearings:

- Remove solvent from the bearings and other washed parts.

- Examine bearings for wear.

- Examine grease-retainer ring and seal. Replace if damaged.

- Grease the bearing, hub and spindle.

3. Maintaining the Cooling system: Flushing or cleaning the cooling system

Following procedure is followed for cleaning of cooling system:

- Run engine until thoroughly warmed.

- Completely drain cooling system while engine is still warm.

- Close drain cocks.

- Refill cooling system with water.

- Add flush compound or cleaner.

- Start engine and operate until normal operating temperature is reached.

- Check external condition of cooling system for any leakage.

- Completely drain the cooling system.

- Refill with water and wash it & then drain it.

- Refill it with appropriate coolant.

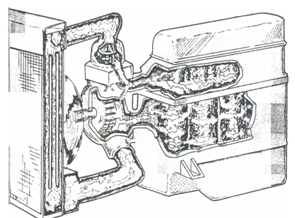

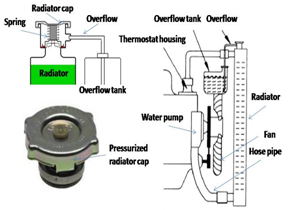

Fig: 3. View of tractor cooling system showing the flow of water (Courtesy: Lab. Manual PAU Ludhiana)

Fig: 4. View of pressurized radiator cap (Courtesy: Sharma & Jain)

References:

Sharma D N. & S. Mukesh (2004). Design of Agricultural Tractor (Principles and Problems) Book Pub. Jain Brothers, New Delhi

Wadhwa D.S., Dhingra H. S. & Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual by, Department of Farm Machinery and Power Engineering, PAU Ludhiana

Sharma, D. N., Tractor Manual, Department of Farm Power and Machinery, CCSHAU

Service and Maintenance Manual of Tractor by Escort Ltd. Faridabad