Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

19 April - 25 April

26 April - 2 May

LESSON 14. Pressure Gauges

14.1 Introduction

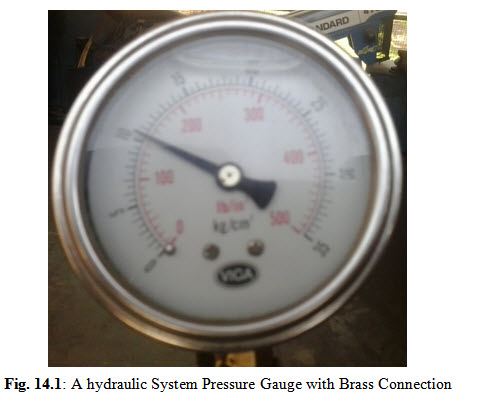

The behaviour of a fluid can be gauged from measurements of pressure or flow. A flow transducer has to be fixed in the line in a way that it obstructs the flow of fluid, thereby changing the local behaviour of fluid. On the other hand, pressure transducers can be added non-intrusively to the pipe through which fluid is flowing.The pressure gauges are generally used to monitor the pressure in filter systems, pumps and pipeline systems in the hydraulic circuit. Pressure gauges are essential in liquid-powered systems to measure pressure to maintain efficient and safe operating levels. Pressure is generally measured in kg/cm2, psi and bar. A typical pressure gauge for a hydraulic system is shown in Fig. 14.1

14.2 Pressure Gauges

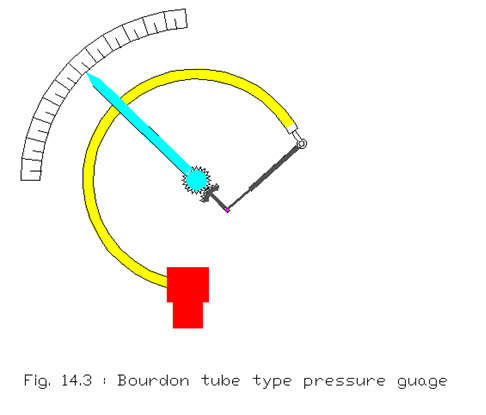

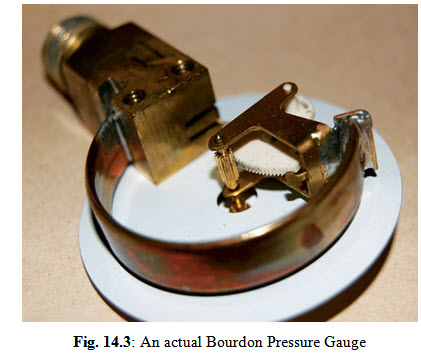

Mostly dial type pressure gauges use a bourdon tube-sensing element generally made of a copper alloy (brass) or stainless steel for measuring pressures. Bourdon tube gauges are widely used in the hydraulic machines or systems to measure pressure and vacuum. Its construction is simple but is considered to be rugged and operation does not require any additional power source. The sensing element is usually a C-shaped tube having oval cross-section, fig 14.2 and 14.3. One end of the tube is exposed to the system pressure through suitable connection. The other end is sealed and free to move. This end is connected to the pointer through mechanical linkages. When pressure is applied to the tube it tends to attain a circular cross-section. This results in distortions which lead to a movement of the free end. The elements of a bourdon tube pressure gauge are shown in Fig. 14.2.

Add sktch

Add sktch

Fig. 14.2: Elements of a Bourdon Pressure Gauge

The movement of the free end of the bourdon tube is converted to circular movement of a pointer using a sector and pinion arrangement. The restraining force is provided by a hair spring. As the external surface of the bourdon tube is exposed to atmospheric pressure, the pointer indicatesgauge pressure. These gauges are generally suitable for most of the fluids. A photograph of bourdon pressure gauge without the pointer is shown in Fig. 14.3. Note the almost flattened C-shaped bourdon tube made of copper alloy.

(Courtesy: http://www.indiamart.com/nationalinstruments/fluid-mechanics.html)

For low pressure ranges, a spiral tube is used to increase the sensitivity.Other configurations of bourdon tube used are helical and twisted type.

Digital gauges use an electronic pressure sensor to measure the pressure and then transmit it to digital display readout. Using this method information can be stored for processing.