Site pages

Current course

Participants

General

Module 1 - Water availability and demand and Natio...

Module 2 - Irrigation projects and schemes of India

Module 3 - Concepts and definitions

Module 4 - Command Area Development and Water Mana...

Module 5 - On-Farm-Development works

Module 6 - Water Productivity

Module 7 - Tank & Tube well irrigation

Module 8 - Remote Sensing and GIS in Water Management

Module 9 - Participatory Irrigation Management

Module 10 - Water Pricing & Auditing

LESSON 18. Chak Water Delivery System – Control Structures For Black Cotton Soil

18.1 Structures in Black Cotton Soils

The structures on the micro-distribution system are very small hydraulic structures and since the cost of each structure involved is comparatively low, not much attention is paid to the design of the foundation. It is often argued that the load of the structures is so small that the foundation presents no problem. But the failure cases show that the structures fail mainly because of developments of crack in structures, which can be attributed to volume changes in the foundations. Thus, the failure is not because of the load involved, but because of the alternate expansion and contraction in the foundations in expansive clayey soils. It is therefore recommended that whenever the soils met with are expansive clays, special treatment for foundation should be given.

The evaluation study of O.F.D. structures in B.C. Soil carried out by D.I.R.D., Pune (March 1988) recommends as follows:

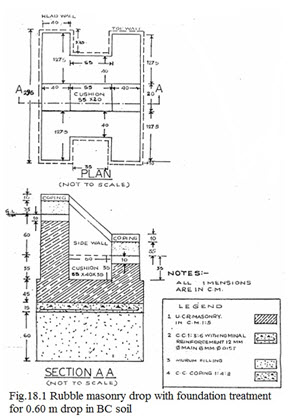

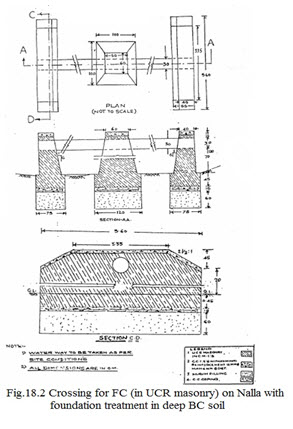

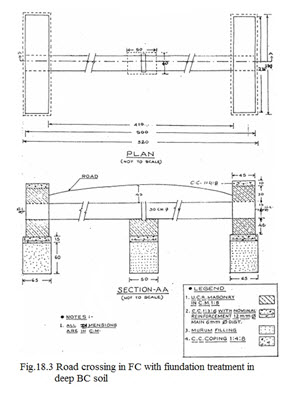

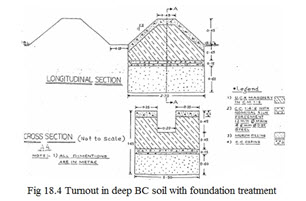

(i) Depth of foundation should necessarily be below the cracking depth.

i.e.1 to 1.2 m where actual observed data is not available.

(ii) The foundation should be first filled with well compacted murum for the depth of about 60 cm.

(iii) Over this, concrete with nominal reinforcement of 15 cm depth be placed.

(iv) Above this, will be provided U.C.R. masonry.

(v) The extra cost of the structure with such foundation treatment will be though substantial but with added advantage.

(vi) Structures in B.C. soil should be of local material for facilitating easy repairs.

(vii) Quality of construction plays important role in making them durable. Hence rigid quality control is necessary.

(viii) Non-conventional structures like pre-cast structures are liable for tampering and are difficult to maintain. Moreover they are costly. Though, they facilitate quick construction, their life is short. Their use, therefore, should be kept to the minimum as far as possible.

(ix) Vertical Hume pipe drops with horizontal pipe, facilitates Field Channel Crossings. These can be tried. Such drops would also be much cheaper and easy for construction.

The details of typical structures in B.C. Soil are shown in Figure-18.1 to 18.4

18.2 Non-Conventional Structures:

The cost of precast structures presently being used with modifications is 3 to 3½ times more than conventional structures. They are very costly and cannot fit into the prescribed cost norms. Hence their use is prohibitive. Moreover, on tampering, they cannot be easily replaced.

Fiberglass structures are 1.5 to 2 times costlier than the conventional structures. But these are lightweight, and liable for tampering. This material lacks bondage with Field Channel material and is difficult to be fixed with the foundation, making it prone for undercaving. Considering the long life of the system, such structures are not recommended.

18.3 Tips for ensuring Quality in Construction of Structures:

(a) The concrete or mortar shall not be prepared by mixing on natural ground, due to which the quality gets deteriorated by mixing earth and other deteriorous materials in concrete or mortar. Galvanized iron sheet 1.5 m x 1.5 m shall be used as platform for mixing. The iron sheet may be provided with wired handle so that it can be dragged easily from one spot to other.

(b) For the good quality and strength, curing of concrete and mortar shall not be ignored. If sufficient water for curing is not available, it can be achieved by apply curing compounds.

(c) Earth back filling behind the structures should be done properly and compacted well.

(d) To achieve the level of accuracies in construction of field channel and structures, the sequence of construction shall be as follows.

i) Excavate field channel as per given alignment, bed gradient and cross section.

ii) Construct Division boxes with design sill levels and check that these match with bed gradients as at that location.

iii) Construct falls and crossings with required level of accuracy.